Data storage media

a data storage and media technology, applied in the field of data storage media, can solve the problems of inability to store and retrieve data, inhibit accurate retrieval of data, damage to read/write devices, etc., and achieve the effect of constant linear velocity and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

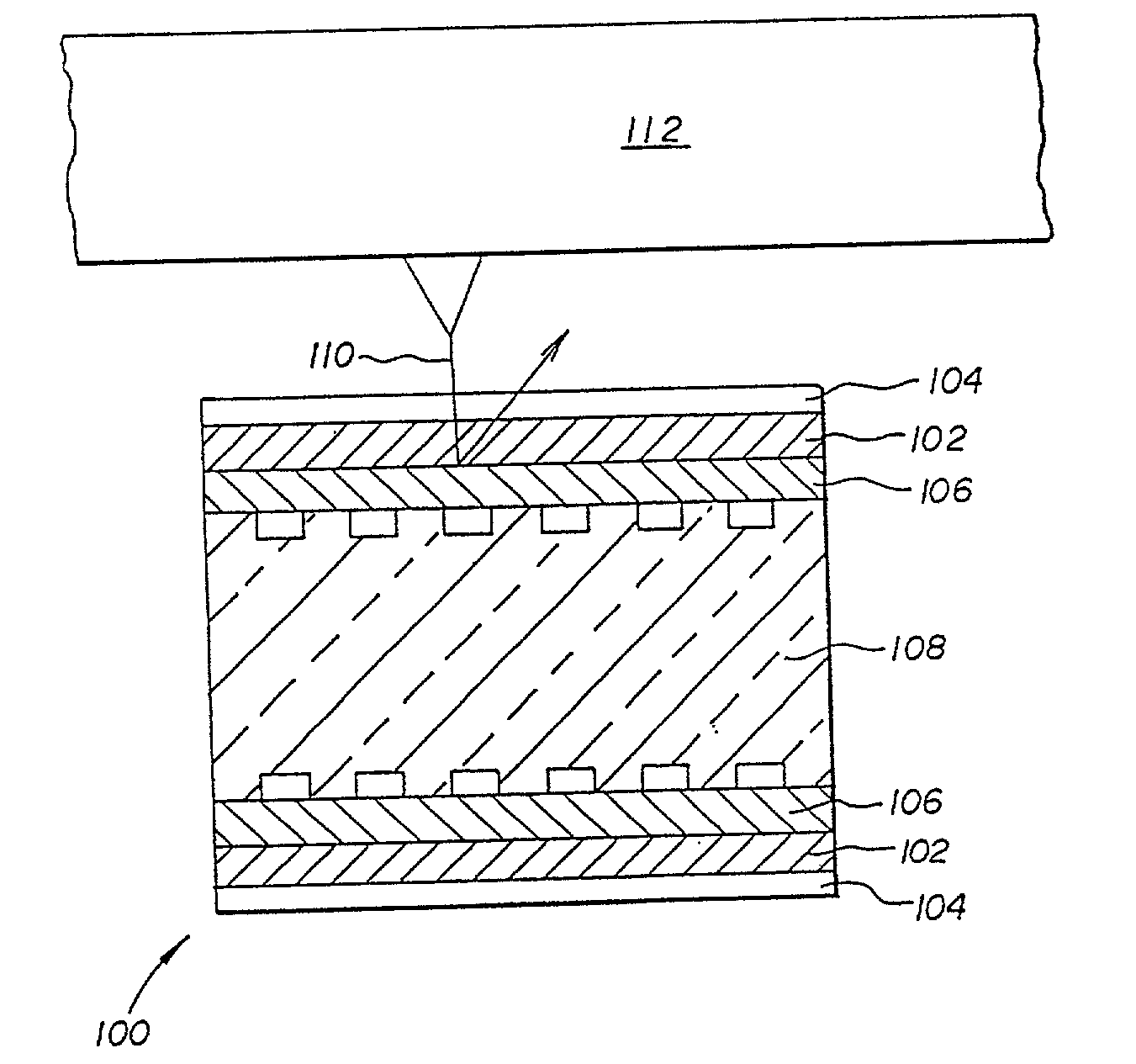

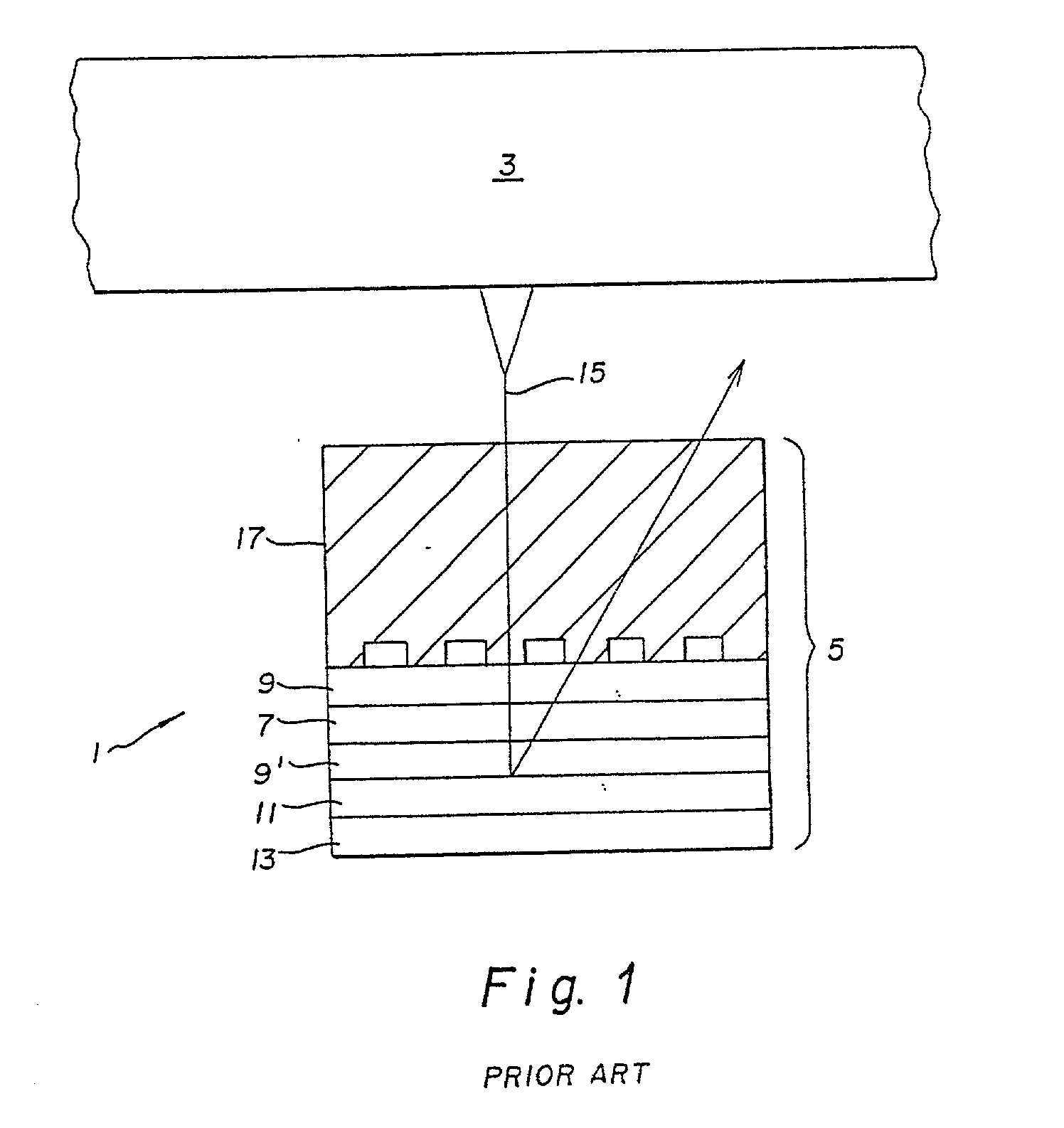

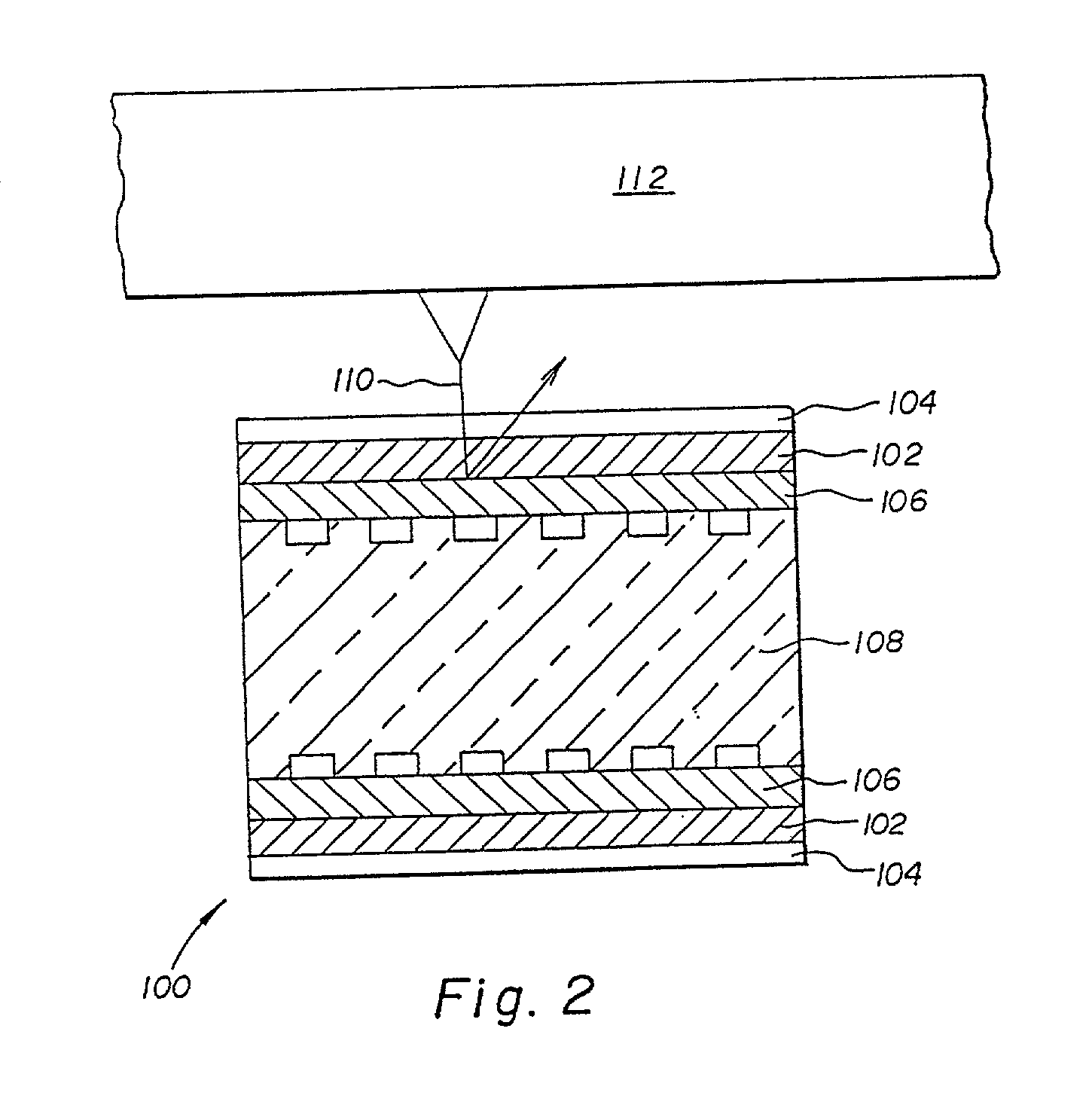

Image

Examples

example 2

[0093] A substrate with dimensions of 130 mm diameter and 1.2 mm thickness can be produced by injection molding of polycarbonate filled with 20 wt % carbon fiber. The material will exhibit a flexural modulus of 1.6 million psi, a mechanical damping coefficient of 0.015, and specific gravity of 1.29 g / cc. The storage media will demonstrate a maximum axial displacement of 0.32 mm during vibrational excitation, and a first modal frequency of 302 Hz.

example 3

[0094] A substrate with outer diameter of 95 mm and thickness of 2 mm was formed with a core of polyphenylene ether / polystryrene (PPE / PS) containing 20 wt % ceramic microfibers and a skin of PPE / PS (40 / 60) by co-injection molding. The microfibers, with average dimensions on the order of 10-20 .mu. length.times.0.3-0.6 .mu. diameter) were significantly smaller than conventional carbon fibers. The surface smoothness of the substrate was improved by approximately a factor of 2 compared to the conventional carbon fiber co-injected disk and the first modal frequency was about 425 Hz. At this frequency, the axial displacement was about 0.15 mm. The benefits compared to the prior art (Comparative Examples #1) are clear.

example 4

[0095] A substrate with outer diameter of 130 mm and thickness of 1.2 mm was formed with a core of 20 wt % carbon fiber-filled polycarbonate and a skin of pure polycarbonate using co-injection molding with a thickness ratio of about 1 unit of core to 1 unit of skin under standard conditions known in the art. The surface smoothness of the substrate was about 10 .ANG. R.sub.a and the first modal frequency was about 210 Hz. At this frequency, the axial displacement was about 1.27 mm; however, the displacement and frequency can be changed with changes in the core to skin ratio. The benefits compared to the prior art (Comparative Example #1) are clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com