Water soluble package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

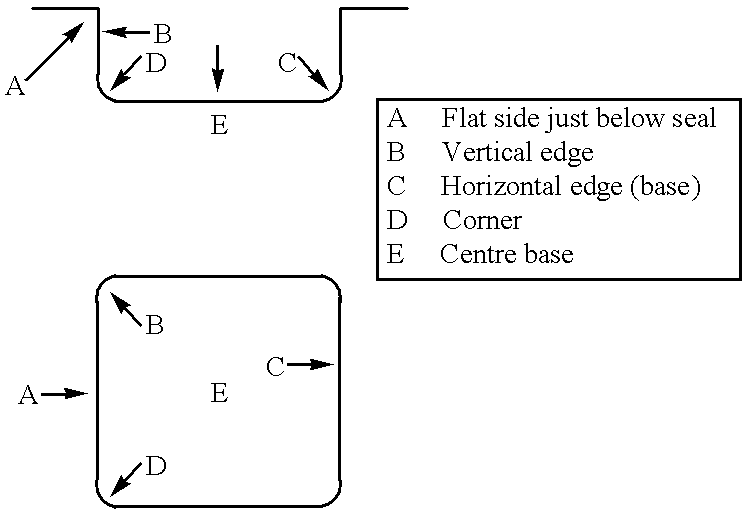

[0029] In this example a thermoforming process is described where a number of packages according to the invention are produced from two sheets of water soluble material. In this regard recesses are formed in the sheet using a forming die having a plurality of cavities with dimensions corresponding generally to the dimensions of the packages to be produced. Further, a single heating plate is used for thermoforming the film for all the cavities, and in the same way a single sealing plate is described.

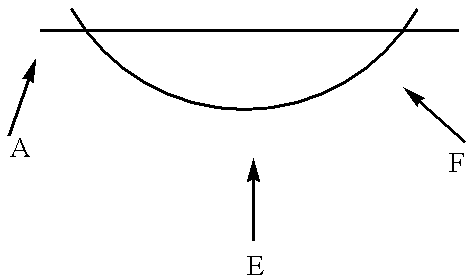

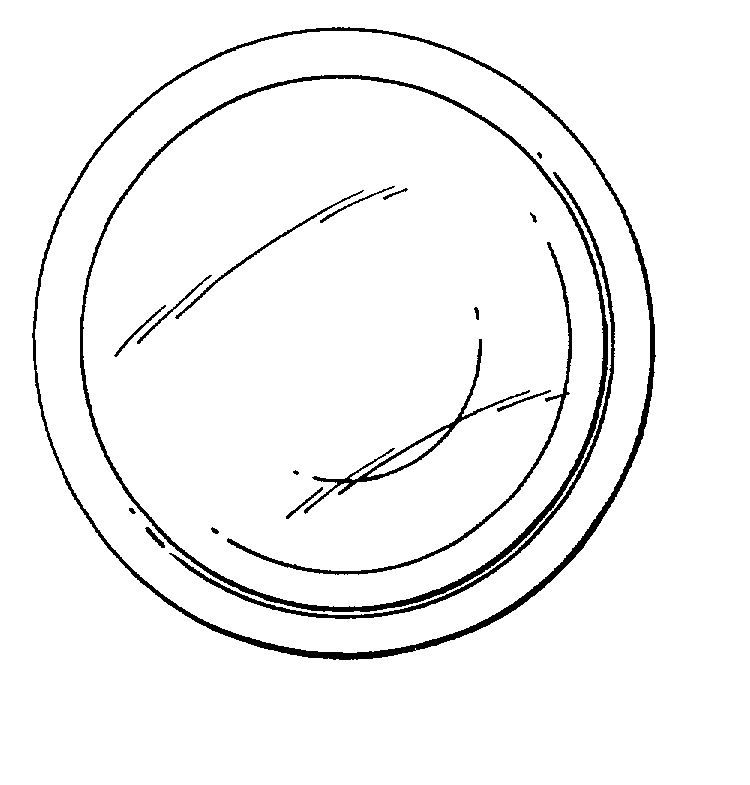

[0030] A first sheet of polyvinyl alcohol film is drawn over a forming die so that the film is placed over the plurality of forming cavities in the die. Each cavity is generally dome shape having a round edge, the edges of the cavities further being radiussed to remove any sharp edges which might damage the film during the forming or sealing steps of the process. Each cavity further includes a raised surrounding flange. In order to maximise package strength; the film is delivered to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility (mass) | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com