Systems and methods for converting cryogenic liquid natural gas to high pressure natural gas and to low pressure natural gas and retain all converted product and to further dispense only by voluntary actions of the user

a technology of liquid natural gas and conversion method, which is applied in the direction of container discharging method, container filling under pressure, transportation and packaging, etc., can solve the problems of limiting the strength of containing pressure and inability to allow high pressure in containers, and achieves enhanced gasification, enhanced gasification, and enhanced thermal transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

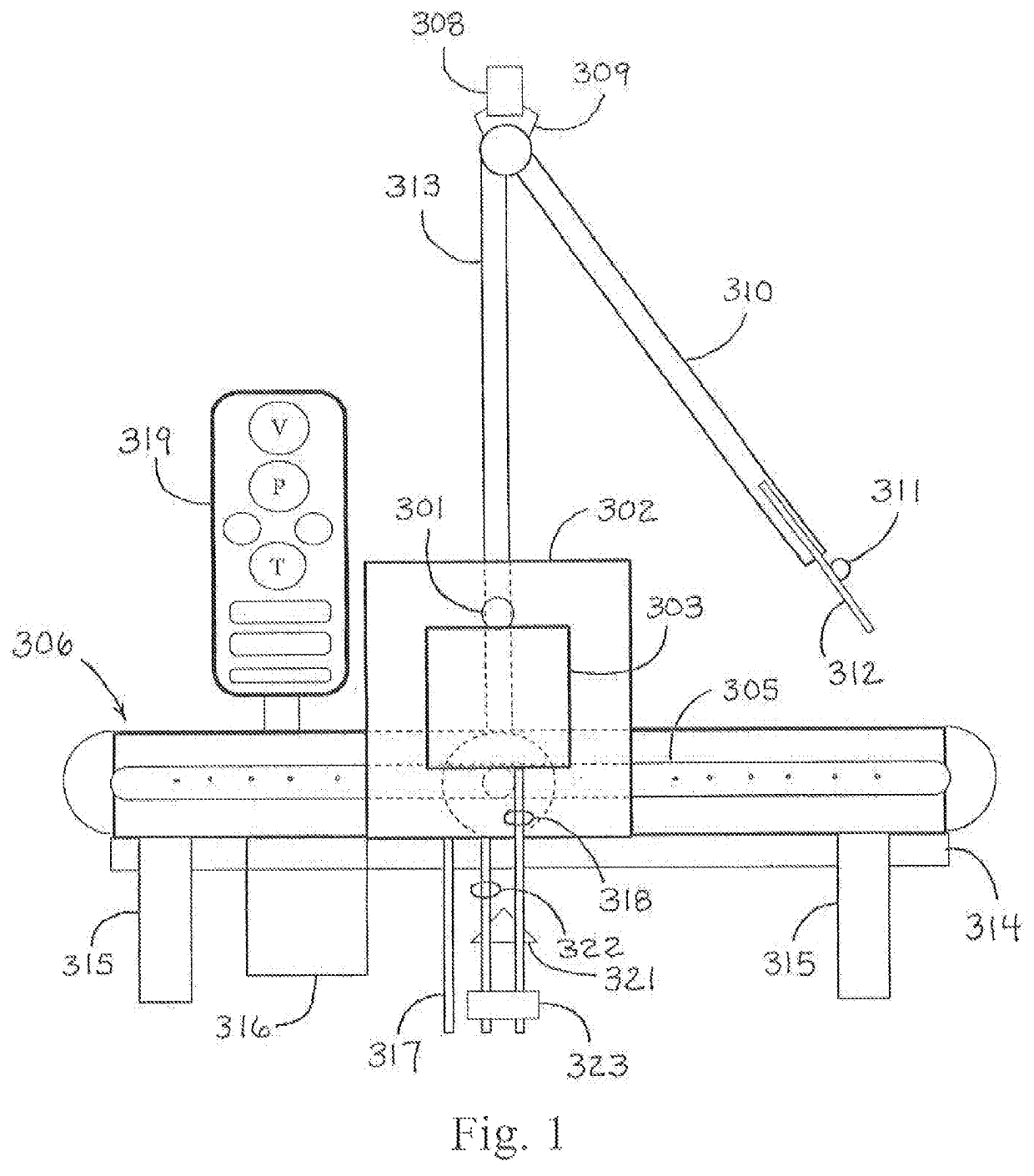

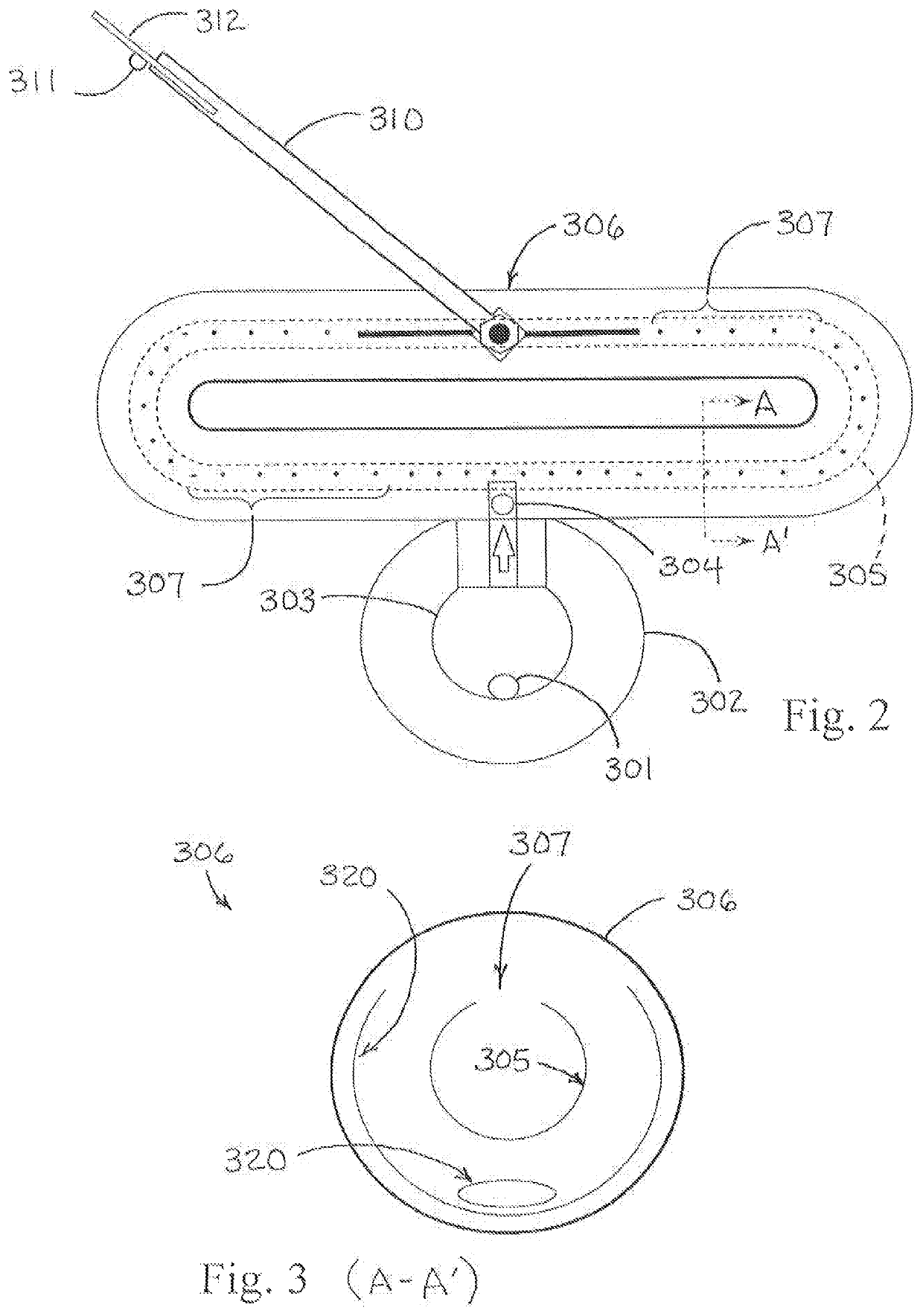

[0053]The present invention provides a LNG to CNG to NG system and method. This system may be optionally enhanced by a system generating hydrogen gas such as an electrolysis at pressure and / or at depth system. The system may also be optionally enhanced by a steam and methane reformation system, including as a heat exchange mechanism described. In the system of FIGS. 1 & 2, an oval CNG expansion chamber 2.4 times the size of the LNG cryogenic container is provided with center tube circles vented. High nickel alloy steel and some layered composites and aluminum alloys are preferably used in the construction of this system where there is contact with cryogenic liquids. The system further may include passive and / or active heat sinks. The system includes LNG fill portal 301 for the cryogenic like vessel. Also disclosed are outer container 302 and inner container 303 for the LNG Again, the approximate ratio of the container volume being 1:2.4 (41.6%) to the volume of oval pressure vessel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com