Flue gas heater by evaporative cooling

A flue gas heater and evaporative cooling technology, applied in lighting and heating equipment, etc., can solve the problems of GGH flue gas leakage and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

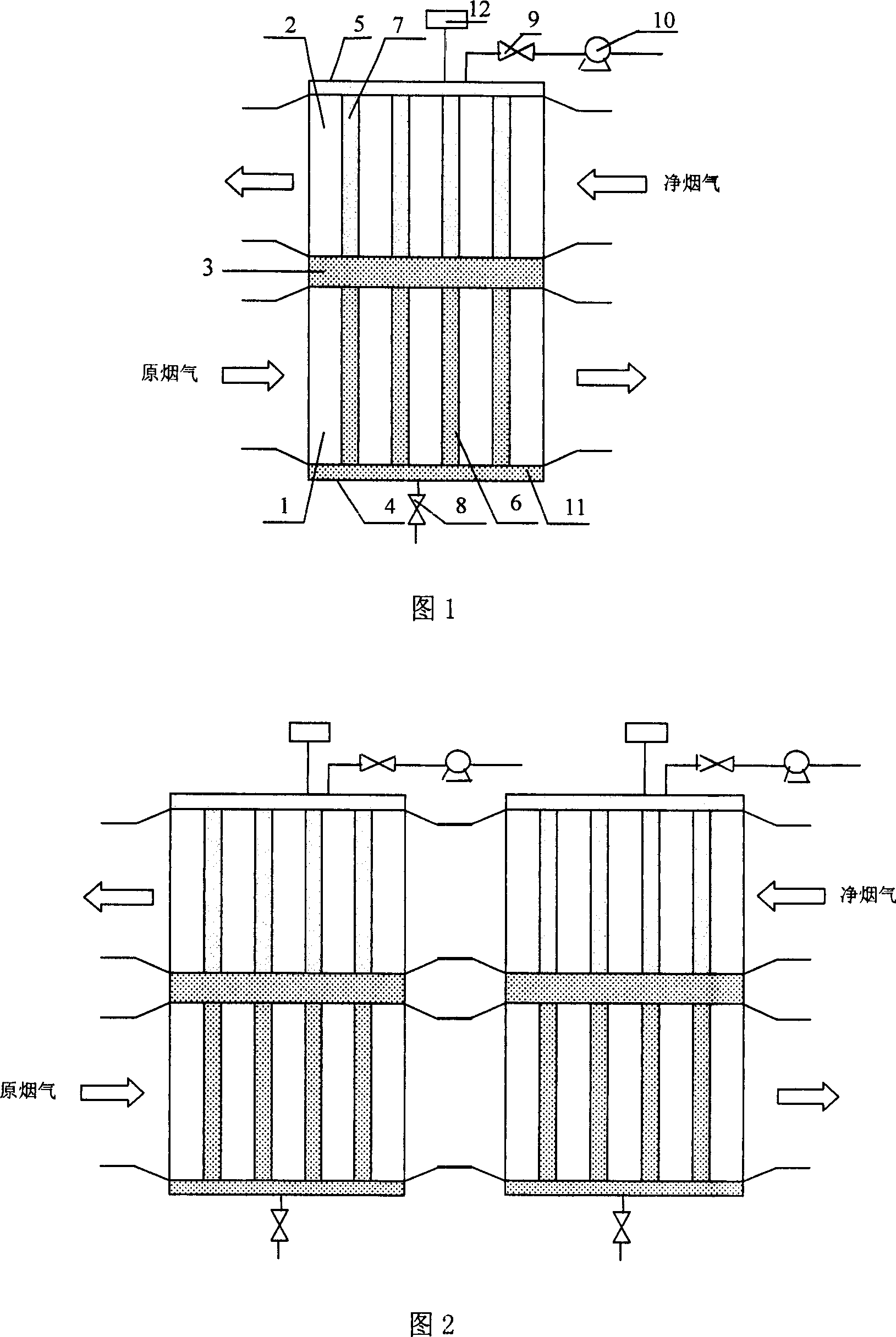

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0010] As shown in Figure 1, the present invention mainly includes three parts: a raw flue gas heat exchanger 1, a clean flue gas heat exchanger 2, and a steam chamber 3. The steam chamber 3 is arranged in two parallel arrangements of the raw flue gas flue and the clean flue gas between gas flues. The raw flue gas heat exchanger 1 is located above the clean flue gas heat exchanger 2 . The raw flue gas heat exchanger 1 and the clean flue gas heat exchanger 2 are directly connected through the steam chamber 3 . The evaporative cooling medium 11 is distilled water, which has the characteristics of colorless, odorless, non-toxic and non-combustible. The medium 11 exists in the form of liquid in the heat exchange tube 6 on the raw flue gas side, and in the form of steam in the heat exchange tube 7 on the clean flue gas side. The liquid medium 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com