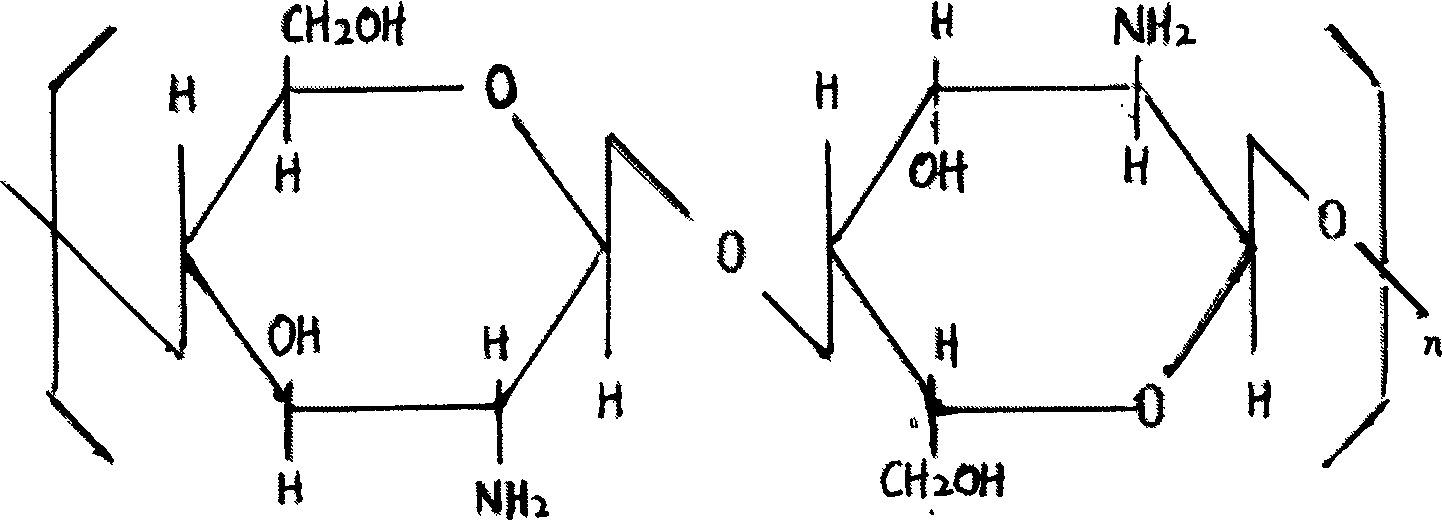

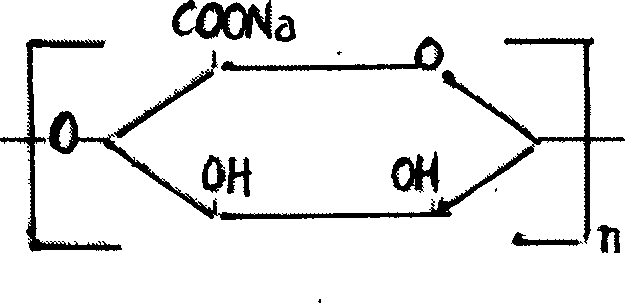

Chitosan fiber, alga fiber and natural fiber blend-spinning yarn and its preparation method and uses

A technology of chitin fiber and blended yarn, which is applied in the field of yarn, and can solve the problems of blended fibers not having hygroscopicity, comfort, gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Prepare each component ratio of the present invention as follows: chitin fiber: seaweed fiber (the weight ratio of sodium alginate, calcium alginate, silver alginate, zinc alginate is 5:2:2:1): blending ratio of tencel fiber (weight ratio) was 5:20:70.

[0079] Above-mentioned each component is made into the production method of the present invention is:

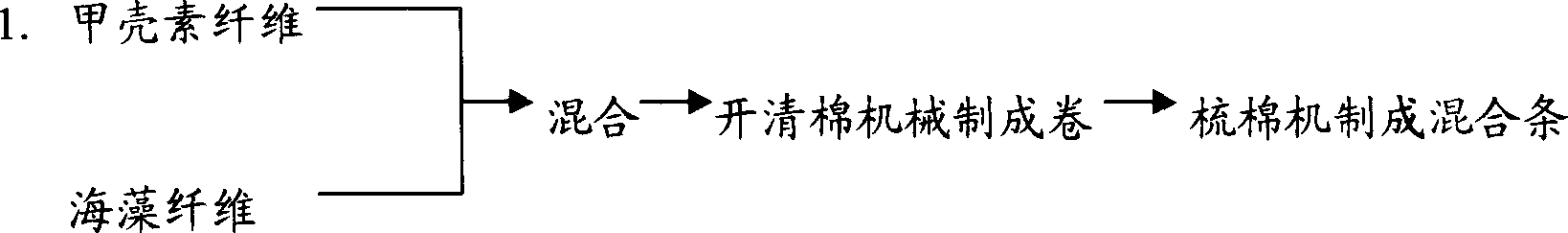

[0080] (1) Chitin fiber and seaweed fiber are mixed, opened and cleaned to make rolls, and carded to make mixed strips;

[0081] (2) Tencel fibers are made into rolls by opening and cleaning machines, slivers by carding machines, rolls by sliver winding machines, and combed slivers by combing machines;

[0082] (3), chitin fiber, seaweed fiber mixed sliver and tencel fiber combed sliver drawing, roving, spun yarn, winding to make chitin fiber, seaweed fiber and tencel fiber blended yarn. Wherein in the present invention, beater speed is 600 rpm in the opening and cleaning process, the licker-in speed is controlled a...

Embodiment 2

[0084] Prepare each component ratio of the present invention as follows: chitin fiber: seaweed fiber (the weight ratio of sodium alginate, silver alginate, zinc alginate is 5:2:2): the blending ratio (weight ratio) of tencel fiber is 20 :5:50.

[0085] Above-mentioned each component is made into the production method of the present invention is:

[0086] (1) Chitin fiber and seaweed fiber are mixed, opened and cleaned to make rolls, and carded to make mixed strips;

[0087] (2) Tencel fibers are made into rolls by opening and cleaning machines, slivers by carding machines, rolls by sliver winding machines, and combed slivers by combing machines;

[0088] (3), chitin fiber, seaweed fiber mixed sliver and tencel fiber combed sliver drawing, roving, spun yarn, winding to make chitin fiber, seaweed fiber and tencel fiber blended yarn. Wherein in the present invention, beater speed is 550 rpm in the opening and cleaning process, the licker-in speed is controlled at 800 rpm in the...

Embodiment 3

[0090] Prepare each component ratio of the present invention as follows: chitin fiber: seaweed fiber (the weight ratio of sodium alginate, silver alginate, zinc alginate is 4:2:2): the blending ratio (weight ratio) of tencel fiber is 30 :40:30.

[0091] Above-mentioned each component is made into the production method of the present invention is:

[0092] (1) Chitin fiber and seaweed fiber are mixed, opened and cleaned to make rolls, and carded to make mixed strips;

[0093] (2) Tencel fibers are made into rolls by opening and cleaning machines, slivers by carding machines, rolls by sliver winding machines, and combed slivers by combing machines;

[0094] (3), chitin fiber, seaweed fiber mixed sliver and tencel fiber combed sliver drawing, roving, spun yarn, winding to make chitin fiber, seaweed fiber and tencel fiber blended yarn. Wherein in the present invention, beater speed is 580 rpm in the opening and cleaning process, the licker-in speed is controlled at 820 rpm in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com