Preparation method for hollow glass mirco-bead

A technology of hollow glass microspheres and hollow microspheres, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as instability, heavy weight, and easy breakage, and achieve the effect of simple structure and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. The preparation method is as follows: (1) After mixing 90 kg of sodium silicate and 10 kg of boric acid raw materials, enter the spray dryer, and spray dry at an air inlet temperature of 300 degrees and an air outlet temperature of 145 degrees. The powder was collected and its powder was shaped into a spherical shape, which was a solid sphere with a diameter of 5 μmr.

[0016] (2) The powder is put into the upper section of the high temperature main tower of the hollow microsphere high temperature energy-saving furnace, and the inlet air temperature of the upper section is 650 degrees. Under the action of natural wind entering through the body through hole, it falls into the first and second stage recoverers respectively, and the temperature of the air outlet of the lower section of the cone is 150 degrees.

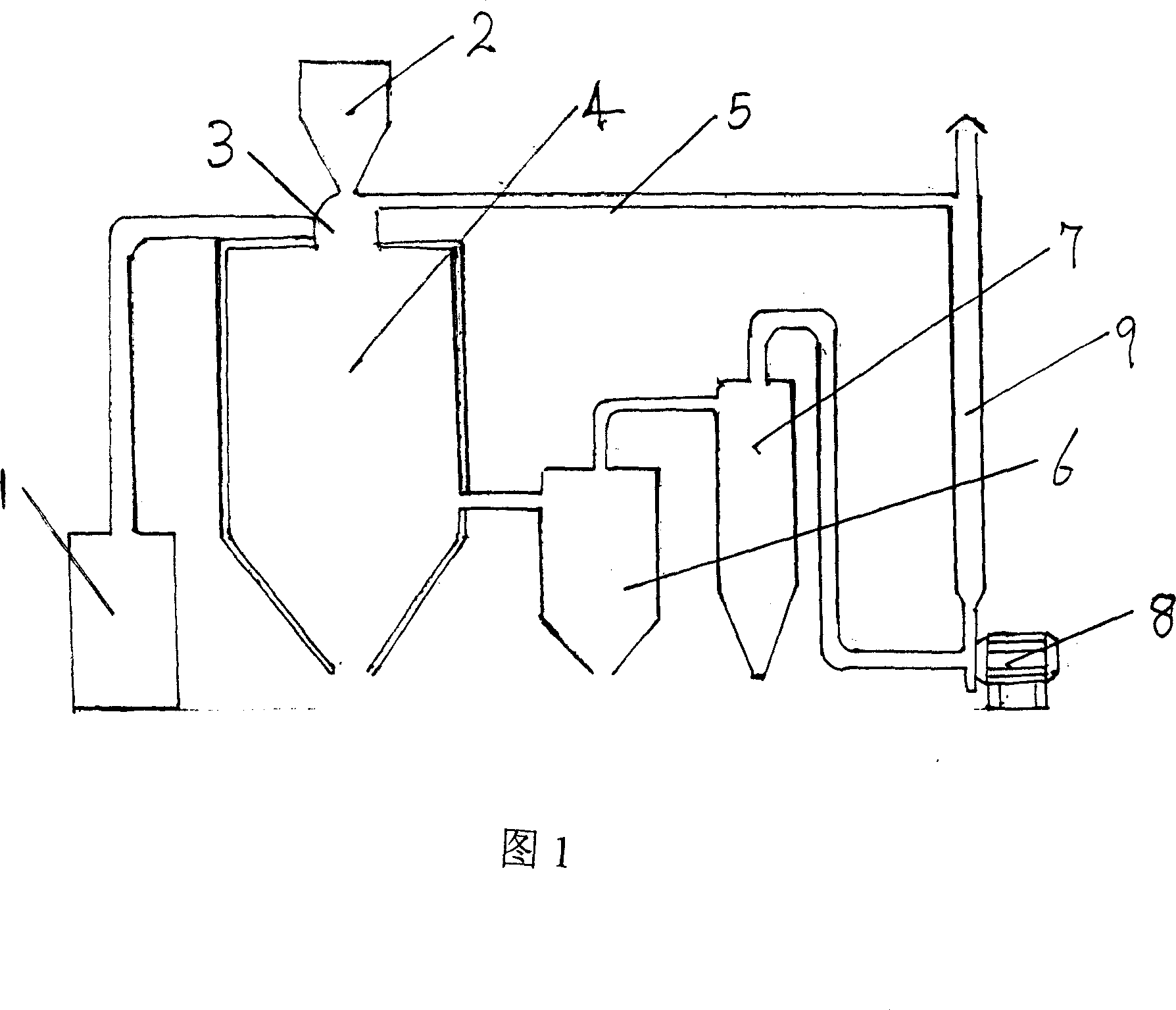

[0017] Adopt the above-mentioned method to prepare the device of hollow glass microsphere, it comprises spray drier, hollow microsphere high-temperature energy-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com