Light emitting diode and its producing method

A technology of light emitting diodes and anode electrodes, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency and high cost of light emitting diodes, and achieve the effects of low cost, high luminous efficiency and obvious quantum effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

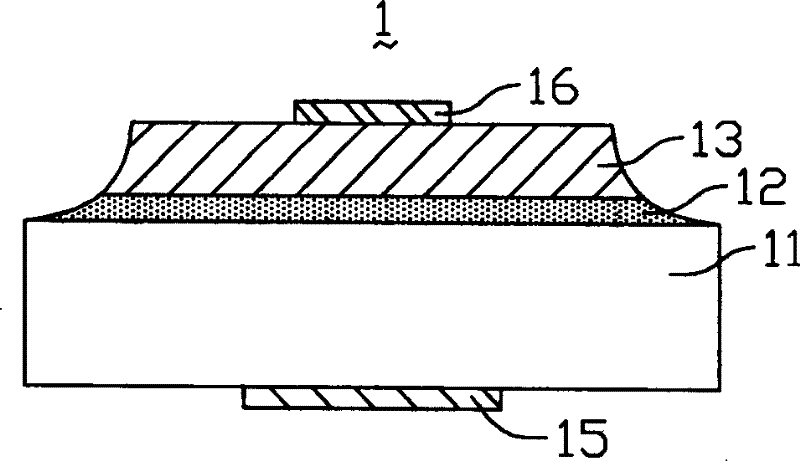

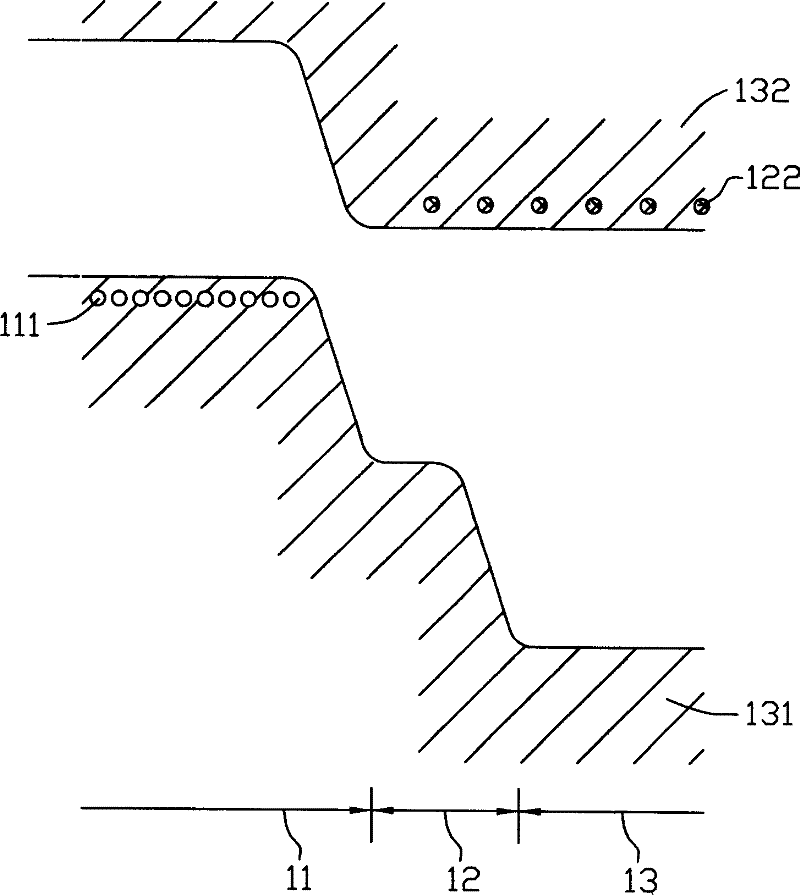

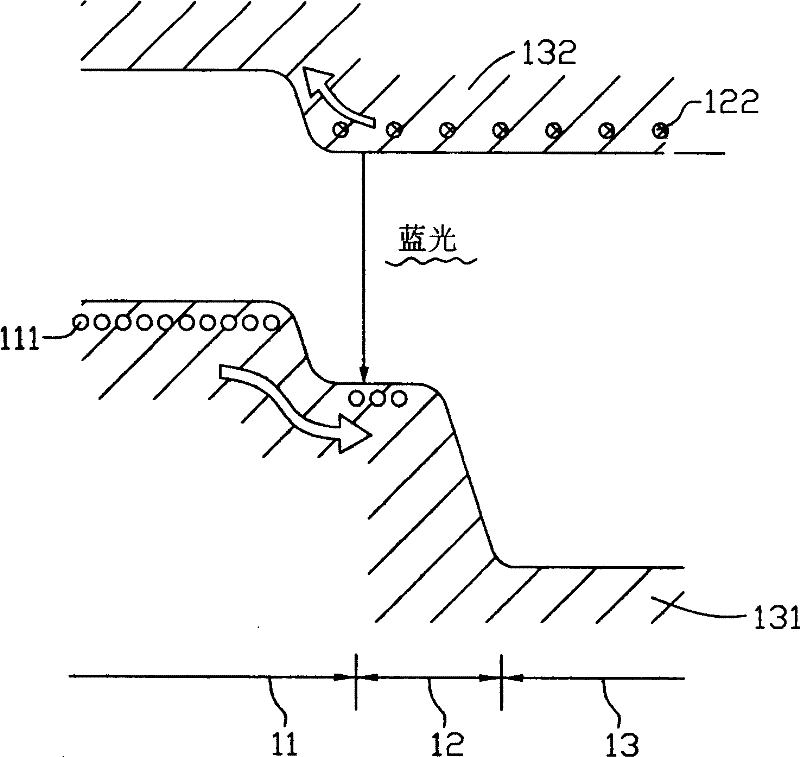

[0019] see Figure 4 , is a schematic diagram of the structure of the light-emitting diode of the present invention. The light emitting diode 2 includes a transparent substrate 21, an anode electrode 22 formed on the transparent substrate 21, an insulating layer 23 formed on the anode electrode 22, a plurality of silicon carbide alloy nanoparticles formed in the insulating layer 23 Point 24, a cathode electrode 25 formed on the insulating layer 23. Wherein, the insulating layer 23 is divided into a first insulating layer 23a and a second insulating layer 23b, and the plurality of silicon carbide alloy nano-dots 24 are located at the interface of the first insulating layer 23a and the second insulating layer 23b and form a Layered distribution. The transparent substrate 21 is made of glass or resin. The anode electrode 22 is Indium Tin Oxide (ITO) or Indium Zinc Oxide (IZO). The insulating layer 23 is silicon nitride with a thickness of 60nm to 150nm. The silicon carbide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com