Self organizing coherent optic fiber wave guide and its producing method

A technology of optical fiber waveguide and manufacturing method, which is applied in the field of optical communication, can solve the problems of complex optical path design, processing, and debugging, and achieve the effect of simplifying the laser system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

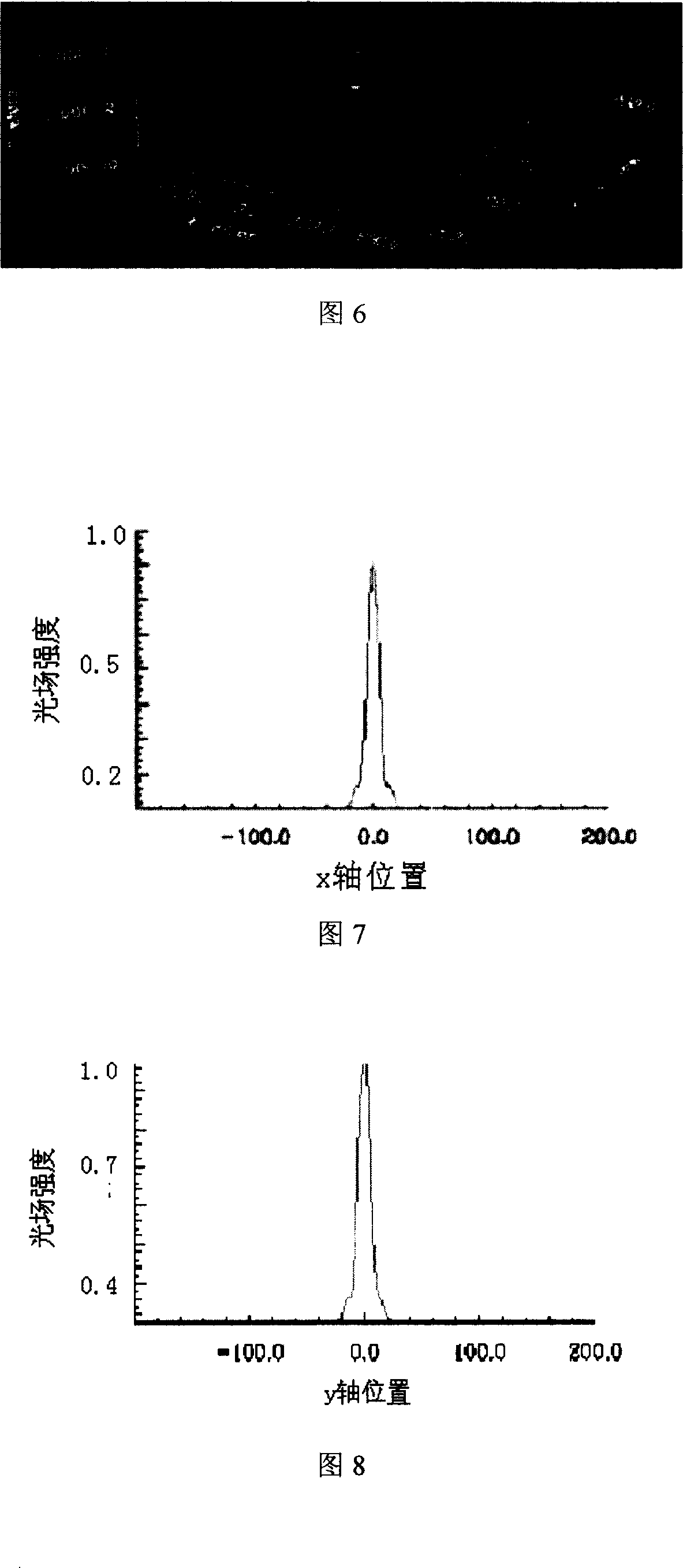

[0040] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and specific preferred implementation modes.

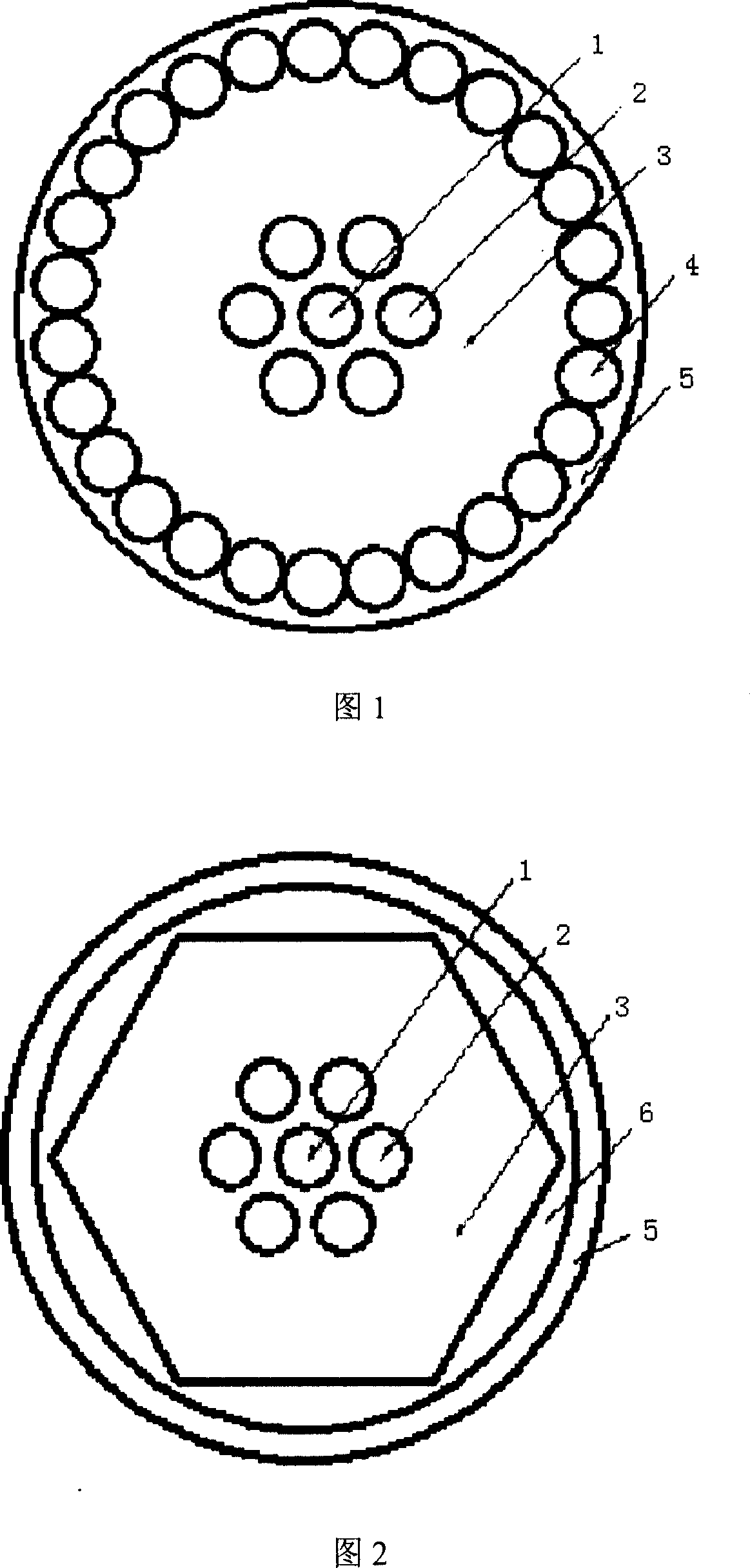

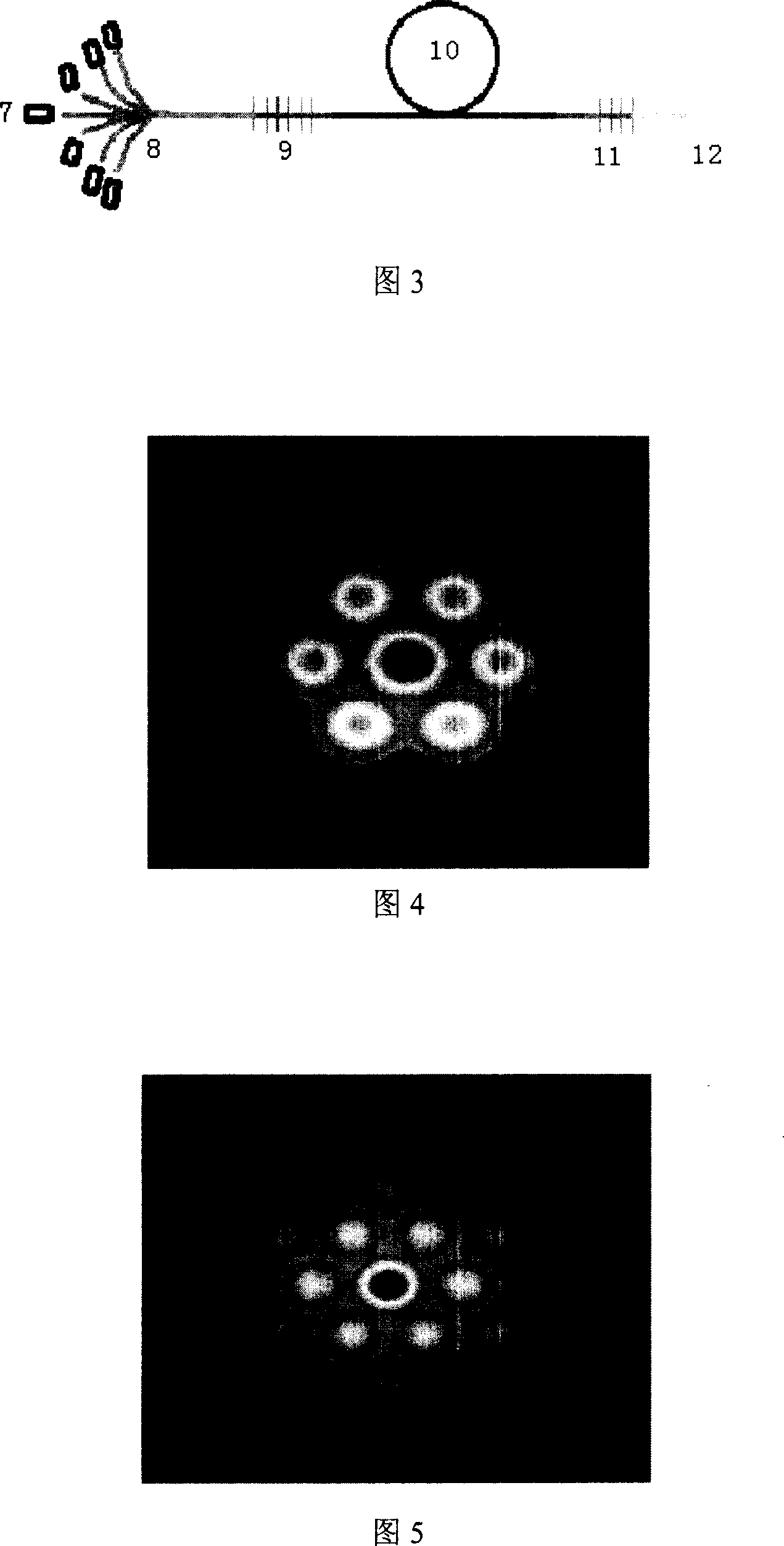

[0041] As shown in Figure 1, a rare earth-doped multi-core optical fiber with a microstructure, in which 1 is the rare earth-doped fiber core in the center of the fiber, 2 is six rare-earth-doped fiber cores at equal distances around 1, and 3 is the rare-earth-doped multi-core fiber core around 1. The circular inner cladding of quartz glass on the periphery of the core, 4 is the outer cladding of annular air holes outside the inner cladding of quartz glass, and 5 is the protective coating of the optical fiber.

[0042] This embodiment of the present invention uses plasma chemical vapor deposition (PCVD) process technology to manufacture high-purity quartz glass tubes, and then on the wire drawing tower, draw wires at a high temperature of 2200 ° C to form high-purity quartz capillaries of 2000 ± 10 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com