Single-cavity double-electrode discharge cavity with micro-channel structure

A discharge cavity and double-electrode technology, which is applied in the field of lasers, can solve the problems of complex manufacturing process and operation method, complex system structure, and high laser price, and achieve the effects of reducing bit arc phenomenon, increasing laser energy, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0054] 1. Basic structure of a single-chamber double-electrode discharge chamber

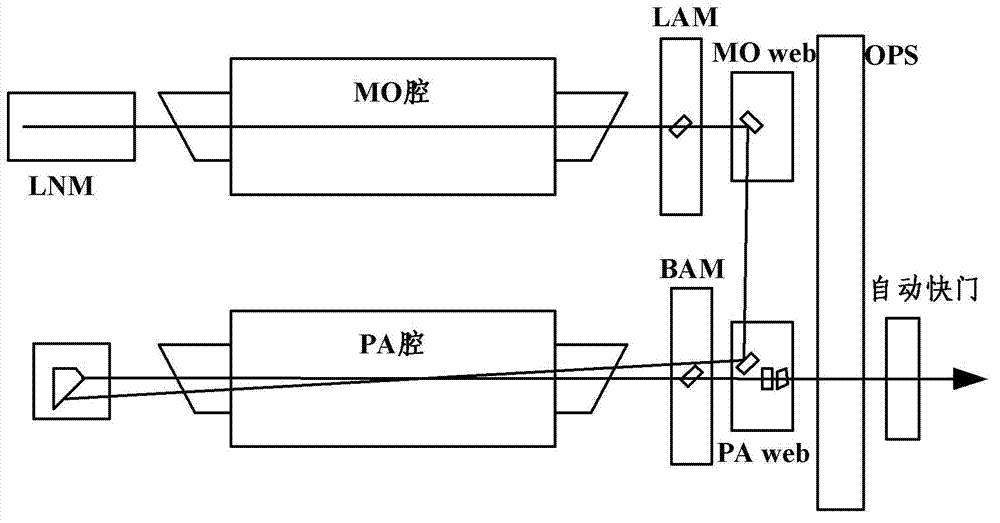

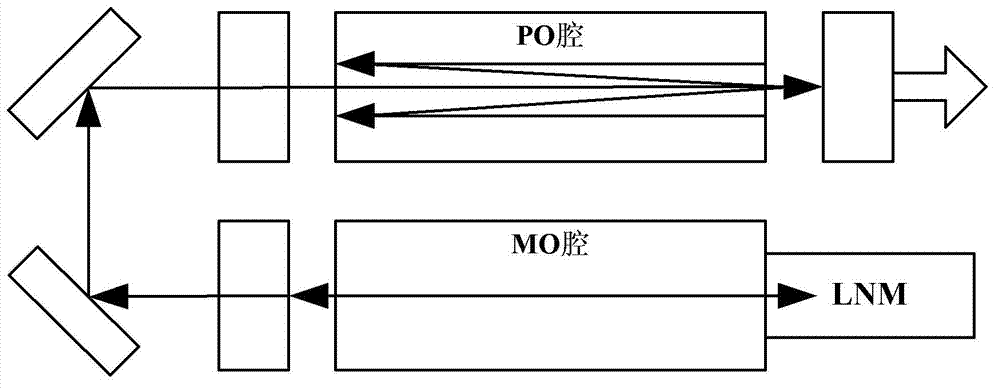

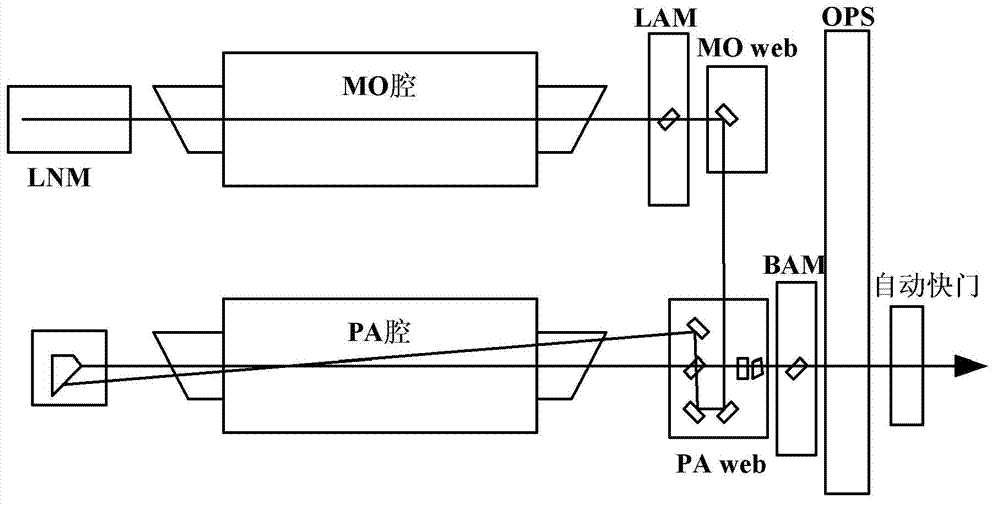

[0055] Figure 6 It is a structural diagram of a single-chamber double-electrode discharge chamber according to an embodiment of the present invention. Such as Figure 6 As shown, the discharge chamber mainly includes a discharge chamber body 1 , two sets of main discharge electrodes, two sets of gas circulation systems, a heat dissipation system, a dust removal device and a high-voltage pulse charging module 4 .

[0056] The discharge chamber body 1 is a closed gas container, which is designed to implement the relevant standards of pressure vessels, and is used to store 3-6 atm corrosive mixed gases, such as including F 2 Excimer haloge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com