Copper heat-exchanging pipe of condenser for bromine refrigerator set

A technology of heat exchange tubes and fins, which is applied in the field of copper heat exchange tubes, can solve problems such as increased manufacturing costs, easy leakage, and small heat dissipation area of fins, so as to improve fatigue resistance and pressure resistance, and reduce temperature edge Interlayer, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

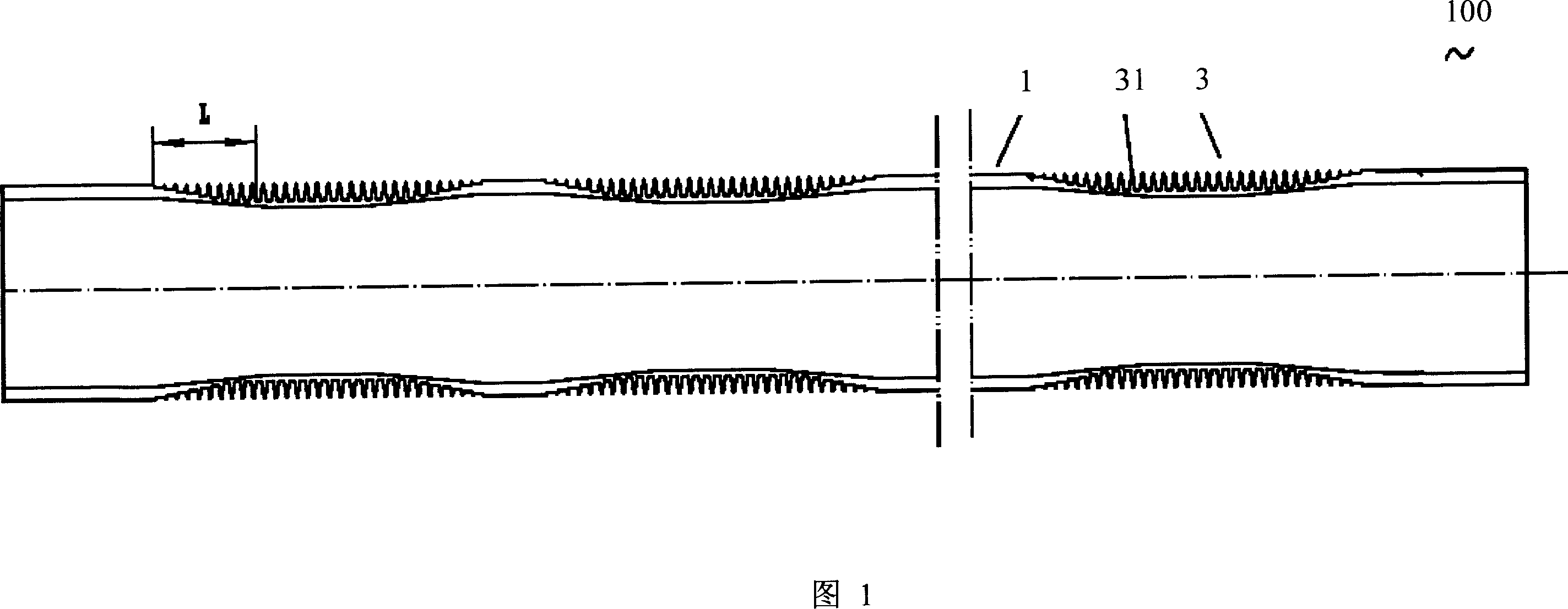

[0017] Referring to FIG. 1 , the heat exchange tube 100 of the present invention includes several polished rods 1 , finned parts 3 with fins 31 , and a transition part 11 transitioning from the polished rods 1 to the fins 3 . Preferably, the heat exchange tube 100 of the present invention is made of copper material.

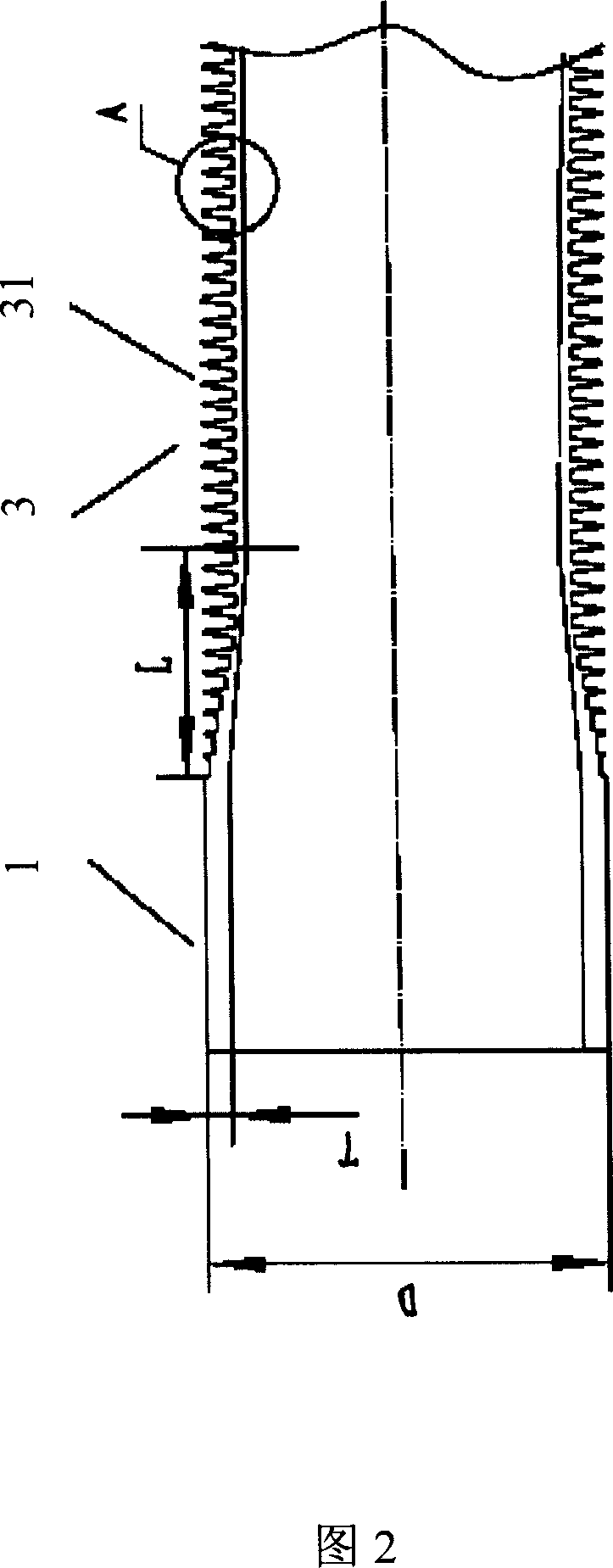

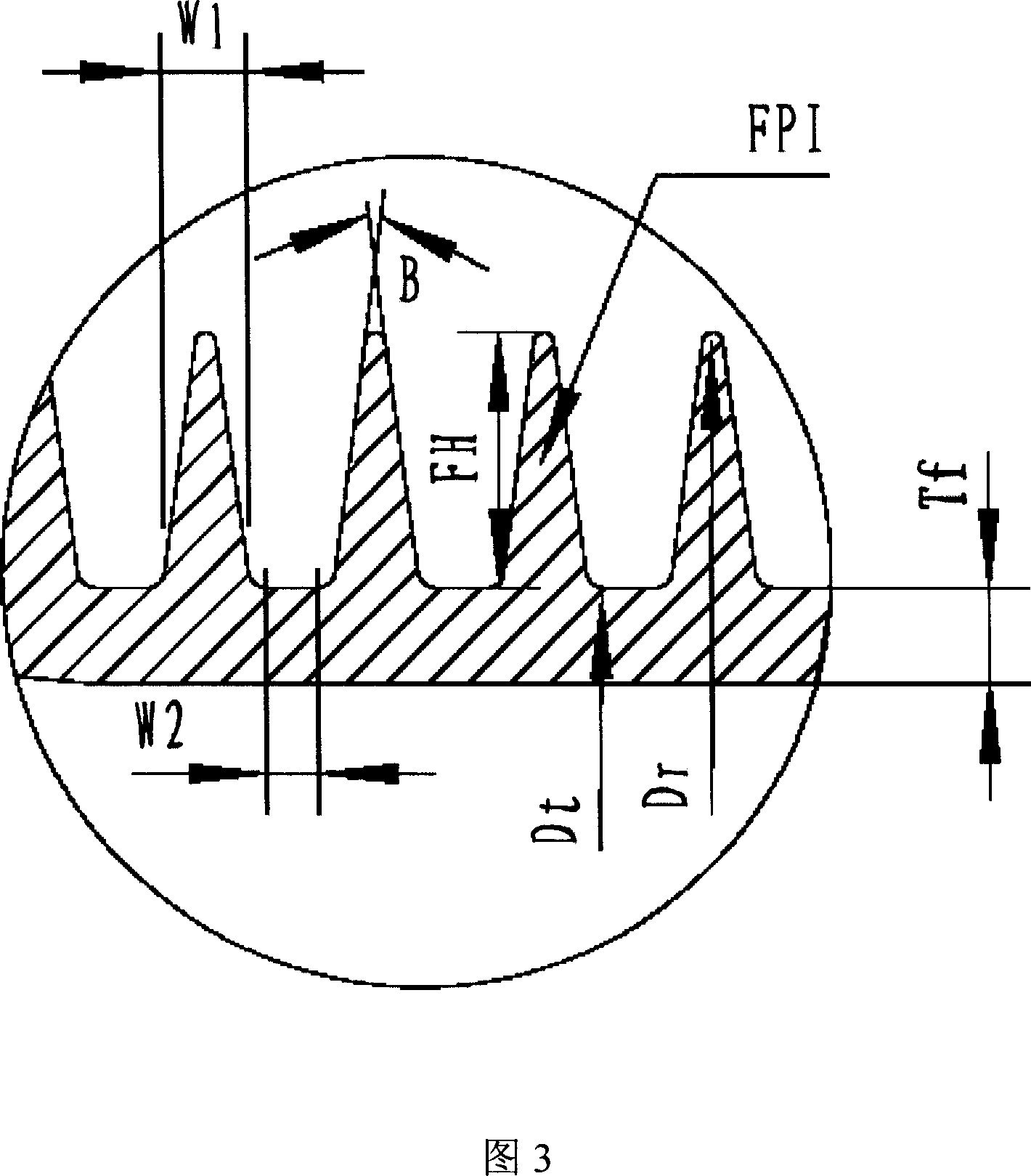

[0018] Please refer to FIG. 2 , the outer diameter D of the polished rod portion 1 of the present invention ranges from 15-20 mm, the wall thickness T ranges from 0.9-1.2 mm, and the length L of the transition portion 11 ranges from 5-25 mm. Since the length of the transition portion of the existing heat exchange tube is at least 30 mm, generally 60 mm, the number of incomplete fins at the transition portion 11 of the heat exchange tube 100 of the present invention is compared to the number of incomplete fins in the existing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com