Method for machining spiral grooved-sided hobbing rear waved edge

A processing method and technology of face milling cutters, which are applied in the direction of milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problem that the wave-blade face milling cutter cannot completely conform to the design drawings, and achieve the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

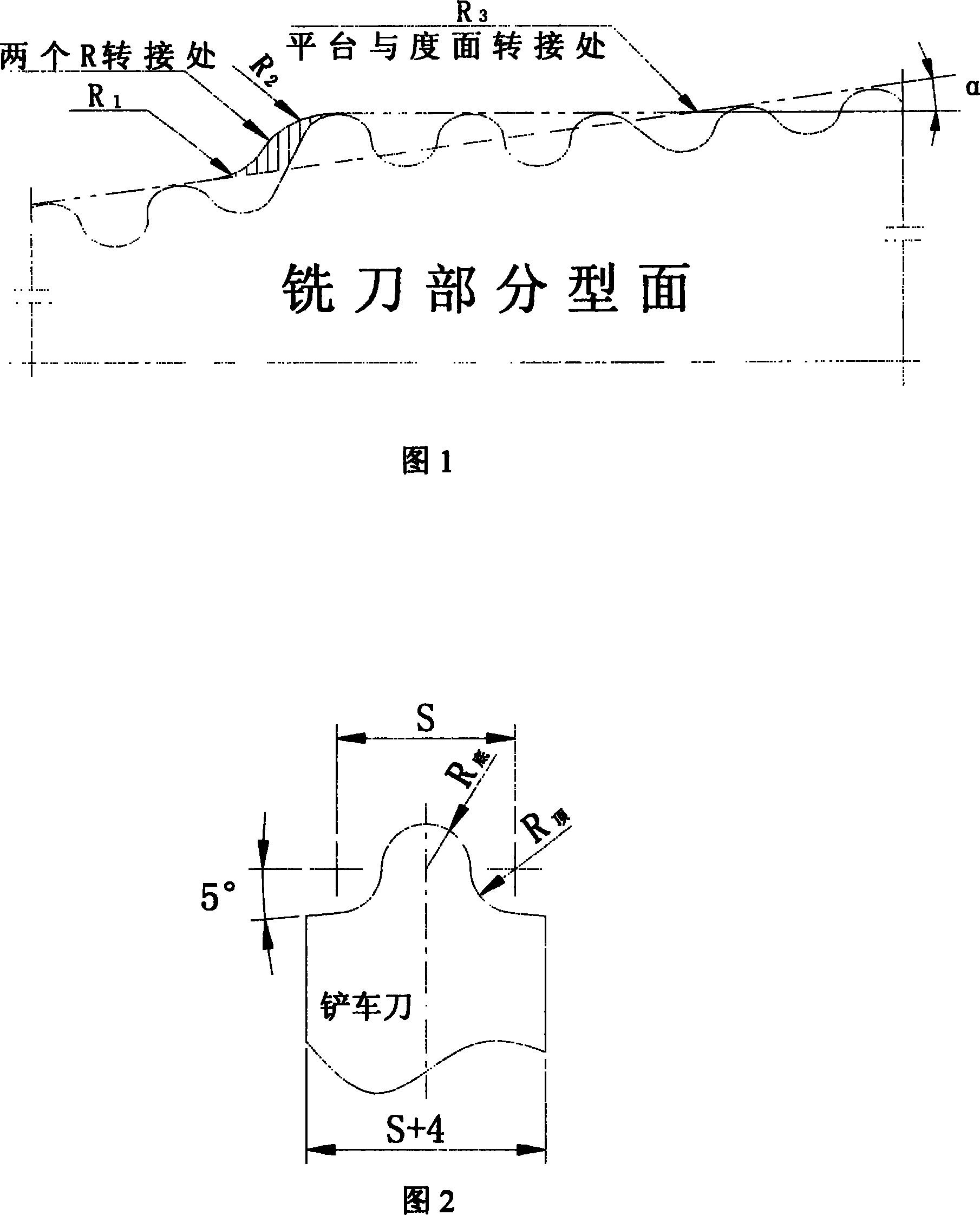

[0039] The number of teeth of the milling cutter is Z=16, the helix angle β=25°, the average diameter of the milling cutter to be processed is D=142.94, and the shoveling amount of the cutter tooth is K=6. The rear wave edge moves to the right, the pitch S=8, the bottom R of the rear wave edge is R1.8, the R of the tooth top is R2.5, and the rear wave edges of adjacent teeth are staggered by 0.5mm along the milling cutter axis.

[0040] Steps:

[0041]1. Make a template according to the profile of the milling cutter to be processed, and install it on the corresponding part of the gear removal machine tool.

[0042] 2. Dressing the grinding wheel profile of the shoveling machine tool.

[0043] The forklift tool is made according to the tooth shape of the rear wave blade, in which the top R of the turning tool is the bottom R of the rear wave blade tooth 底 , both sides of the top R are smoothly transferred to half of the rear wave edge addendum R 顶 And it is tangent to the fi...

example 2

[0059] The number of teeth of the milling cutter is Z=16, the helix angle β=25°, the average diameter of the milling cutter to be processed is D=132.60, and the shoveling amount of the cutter tooth is K=6. The rear wave edge moves to the right, the pitch S=8, the bottom R of the rear wave edge is R1.8, the R of the tooth top is R2.5, and the rear wave edges of adjacent teeth are staggered by 0.5mm along the milling cutter axis.

[0060] Steps:

[0061] Change the differential hanging gear of the shovel gear machine to I 2 =55×60 / 62×39, and the rest of the operation steps are the same as Example 1.

example 3

[0063] The number of teeth of the milling cutter is Z=16, the helix angle β=25°, the average diameter of the milling cutter to be processed is D=146.02, and the shoveling amount of the cutter tooth is K=6.2. The rear wave edge moves to the right, the pitch S=8, the bottom R of the rear wave edge is R1.8, the R of the tooth top is R2.5, and the rear wave edges of adjacent teeth are staggered by 0.5mm along the milling cutter axis.

[0064] Steps:

[0065] Change the differential hanging gear of the shovel gear machine to I 2 =50×58 / 60×39, the actual K value is changed to: K 实际 = 6.2. The rest of the operation steps are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com