Semiconductor device, manufacturing method for semiconductor device, electronic component, circuit board, and electronic device

A technology for electronic components and manufacturing methods, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

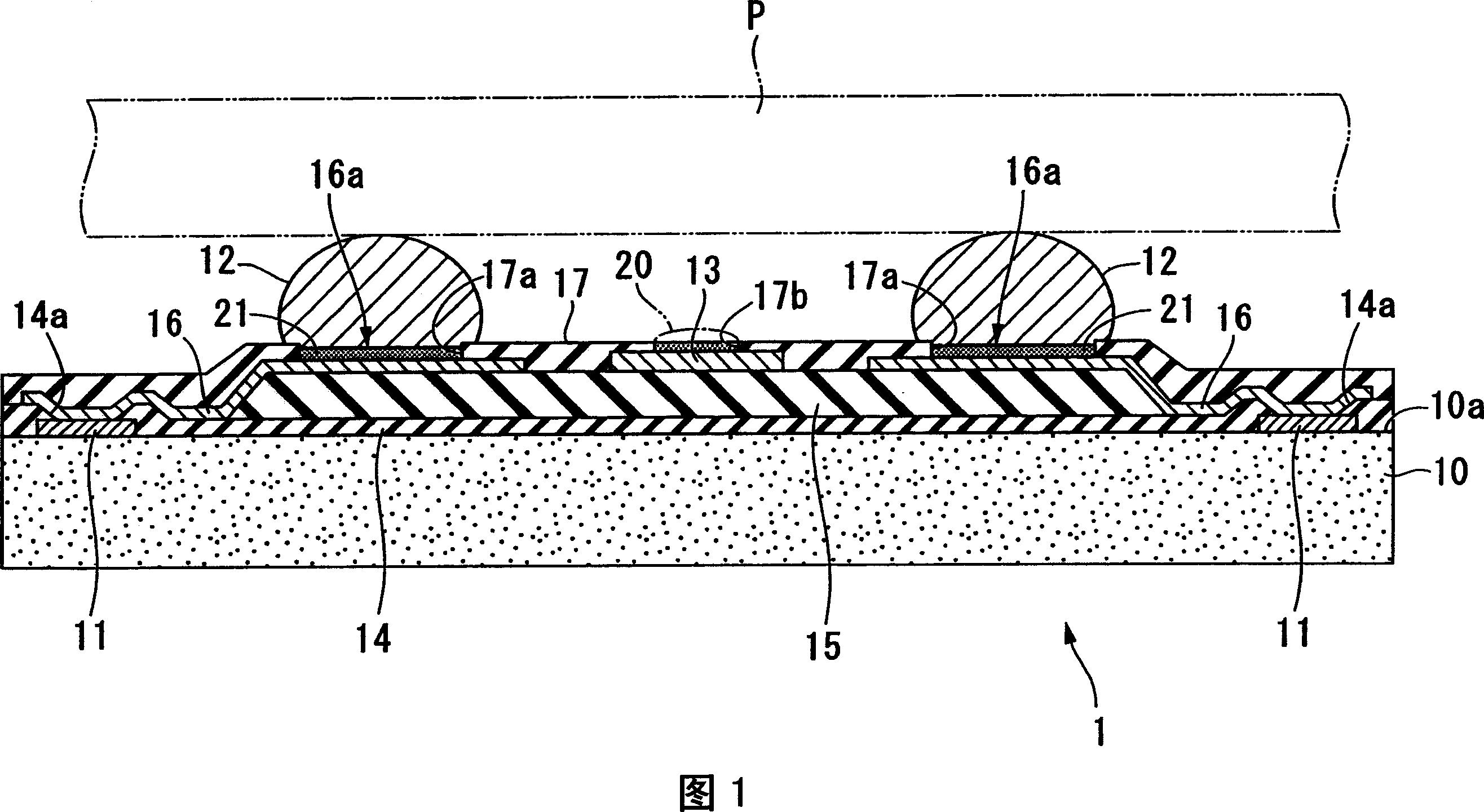

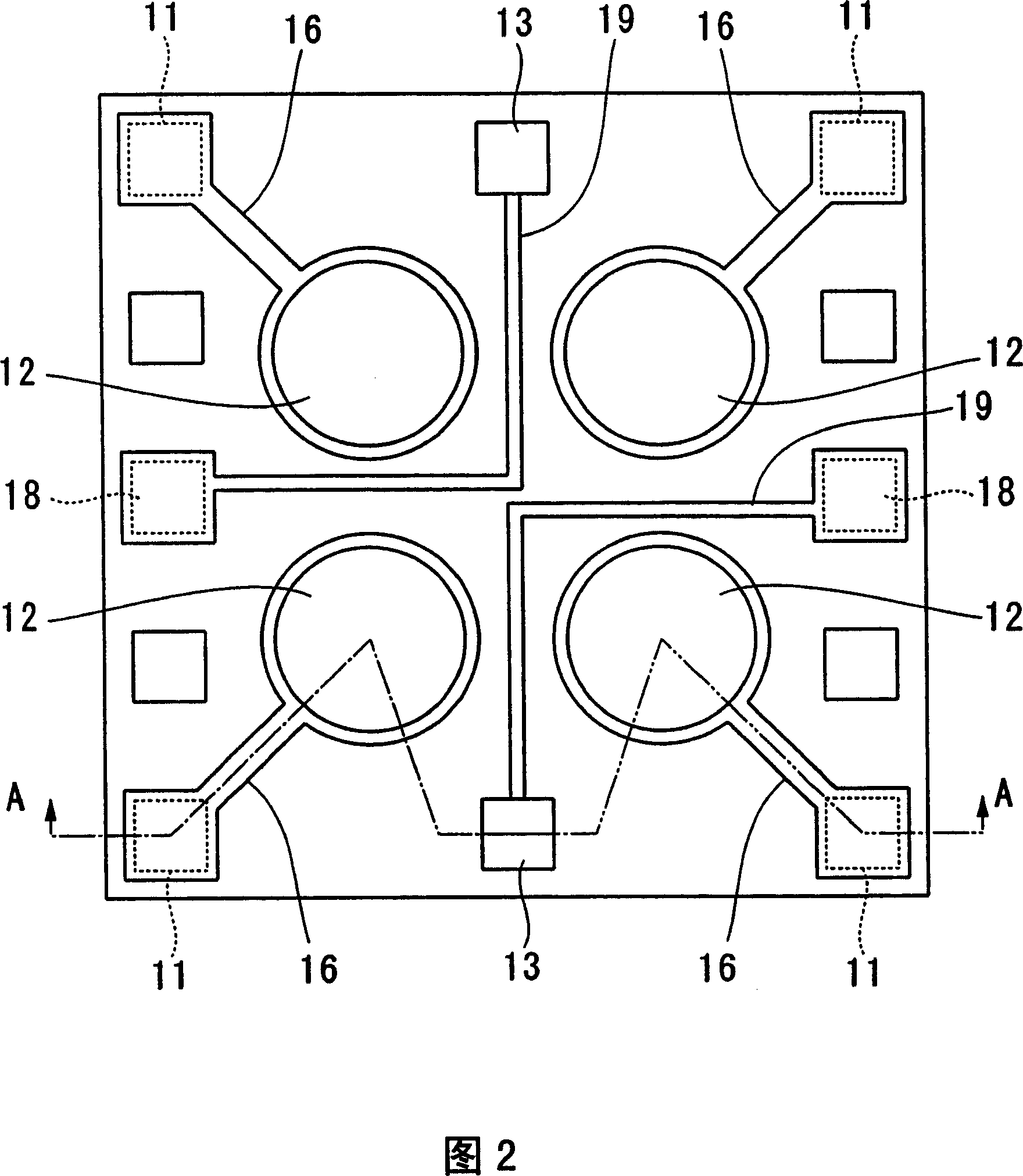

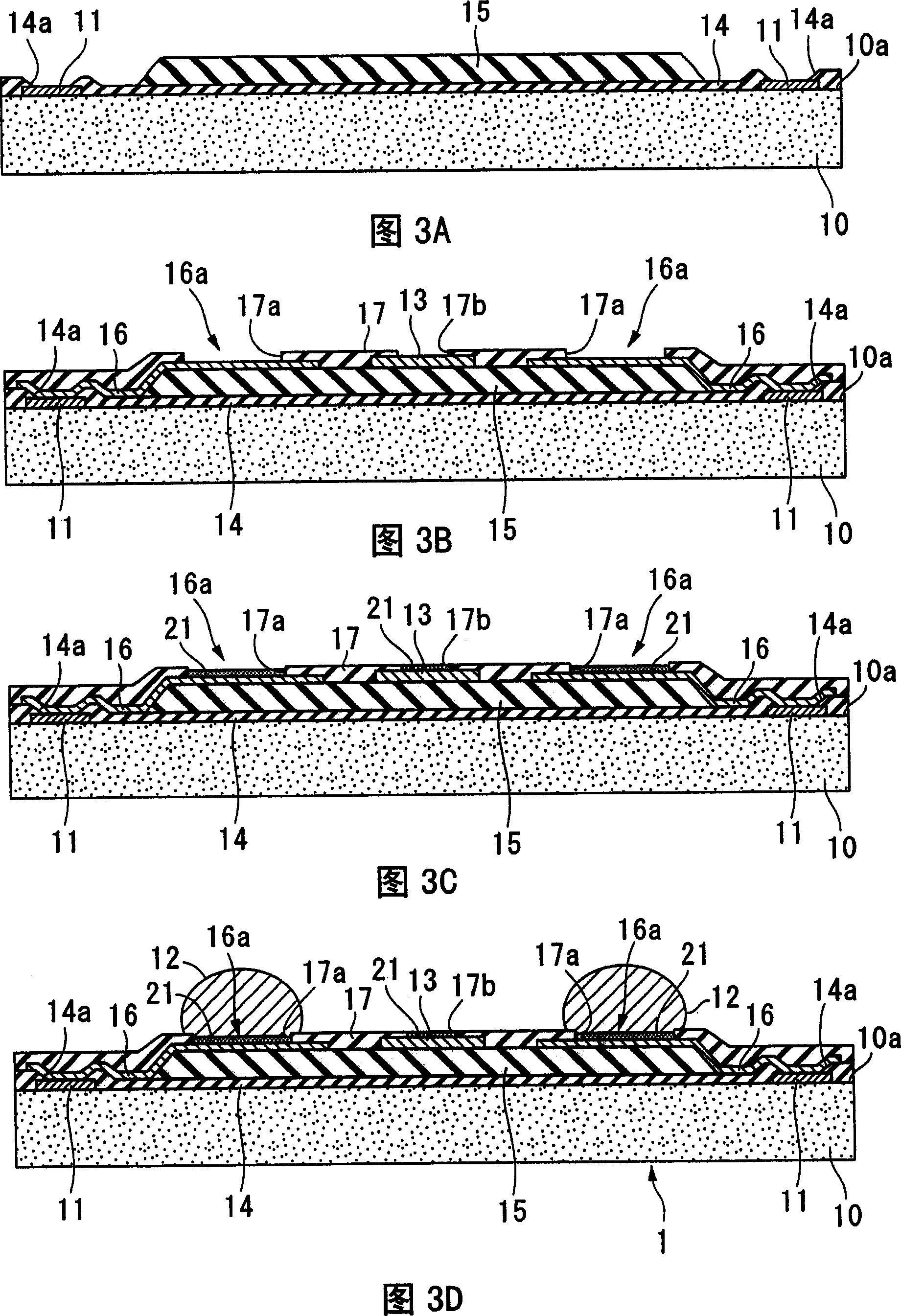

[0060] Embodiments of a semiconductor device, a method of manufacturing a semiconductor device, an electronic component, a circuit board, and an electronic device according to the present invention will be described below with reference to FIGS. 1 to 7 .

[0061] [semiconductor device]

[0062] 1 and 2 are diagrams showing an embodiment of a semiconductor device of the present invention. In these figures, reference numeral 1 is a semiconductor device having a wafer-level CSP (W-CSP) structure.

[0063] In addition, the side sectional view of FIG. 1 is a sectional view along the line A-A in the schematic diagram of FIG. 2 .

[0064] As shown in FIG. 1 , a semiconductor device 1 includes a silicon substrate (semiconductor substrate) 10 , first electrodes 11 , external connection terminals 12 , and connection terminals 13 .

[0065] Here, an integrated circuit (not shown) including semiconductor elements such as transistors and memory elements is formed on a silicon substrate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com