Circular dense phase fluidizing desulfurization apparatus

A desulfurization equipment and circulating fluidization technology, applied in the field of environmental engineering, can solve the problems of cumbersome construction and processing procedures, high concentration of smoke and dust when leaving the tower, and complex structure, and achieve the goals of reducing transportation height, improving utilization efficiency, and facilitating processing and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

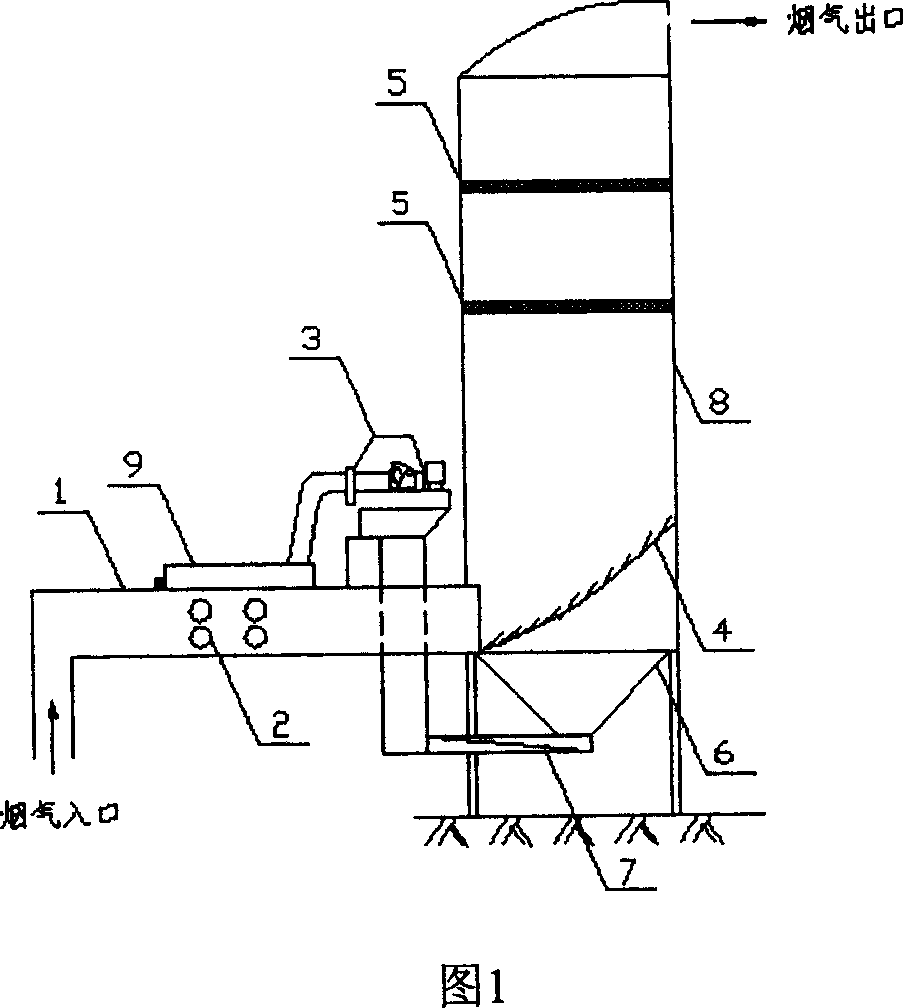

[0024] As shown in Figure 1, the reactor is a cylindrical tower, and the flue gas enters the reactor from bottom to top for desulfurization reaction. A square venturi distribution system (composed of a square venturi tube, a stirring device and a distributor) is installed at the flue gas inlet. The stirring device fully disperses the desulfurizer material so that it is evenly mixed with the flue gas and enters the reaction tower together. After being diverted by the guide plate, the material and flue gas undergo desulfurization reaction inside the reactor, and the state of the material and flue gas inside the reactor is between the two states of circulating fluidization and dense phase, which ensures the full progress of the desulfurization reaction. A screen filter device is installed inside the reactor to retain part of the material and let it fall through the deflector into the collecting hopper for recycling. At the same time, the screen filter device also ensures that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com