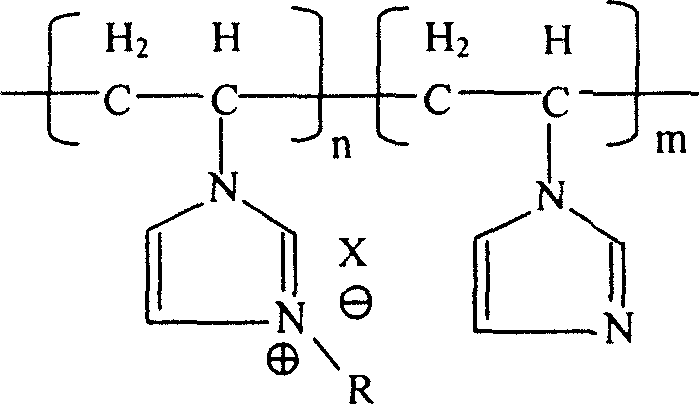

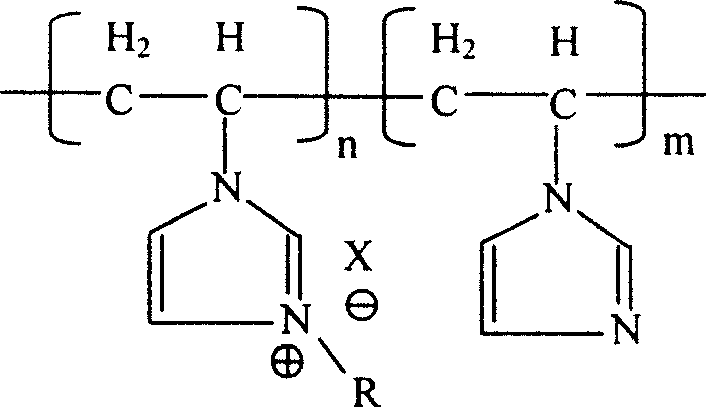

Poly(N- ethenyl-N'-alkyl- imidazole) ion liquid structural material and its preparation method

A technology for ionic liquids and structural materials, which is applied in the field of poly(N-vinyl-N'-alkyl-imidazole) ionic liquid structural materials and its preparation, and can solve problems that do not involve the molar fraction of structural segments containing ionic liquids , to achieve the effects of easy processing, wide electrochemical window and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 23.5 grams of vinylimidazole monomers (0.25 moles in total) were packed into a 150ml three-necked flask with a reflux condenser and a feeding tube, added benzene to make the solution 80ml, stirred, degassed, and filled with nitrogen for protection. After dissolving 0.1 g of azobisisobutyronitrile (AIBN) in 5 ml of benzene, place it in the feeding tube. The flask was heated to 60 °C, the AIBN solution was added into the flask from the feeding tube within one minute, and the polymerization reaction started. After 3 hours of polymerization reaction, the solvent was evaporated, and vacuum-dried in a vacuum oven at 80° C. for 24 hours to constant weight to obtain polyvinylimidazole. The weighing method is used for calculation and analysis, and the reaction conversion rate is 82.0% based on the addition of vinylimidazole monomer.

Embodiment 2

[0027] Put 4.7 grams (0.05 moles in terms of vinylimidazole monomer) of polyvinylimidazole into a three-necked flask with a reflux condenser, add 100 grams of absolute ethanol to dissolve it, and then add 8.2 grams (0.06 moles) of bromine Substitute n-butane (the molar ratio to vinylimidazole monomer is 1.2:1), heat up to ethanol reflux through a constant temperature bath under stirring, and the reaction continues for 24 hours, maintaining a weak nitrogen flow as a protection during the entire reaction process. gas. The ethanol solvent used in the reaction was evaporated, and the reaction product was vacuum-dried in a vacuum oven at 80°C for 24 hours to constant weight to obtain brominated n-butylpolyvinylimidazole, and the reaction combination rate was 85.0% based on vinylimidazole monomer .

Embodiment 3

[0029] Repeat Example 2, add 10.9 grams (0.1 mole) bromoethane (the molar ratio with vinylimidazole monomer is 2: 1) to replace brominated n-butane, and the reaction combination rate is calculated in terms of vinylimidazole monomer 89.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com