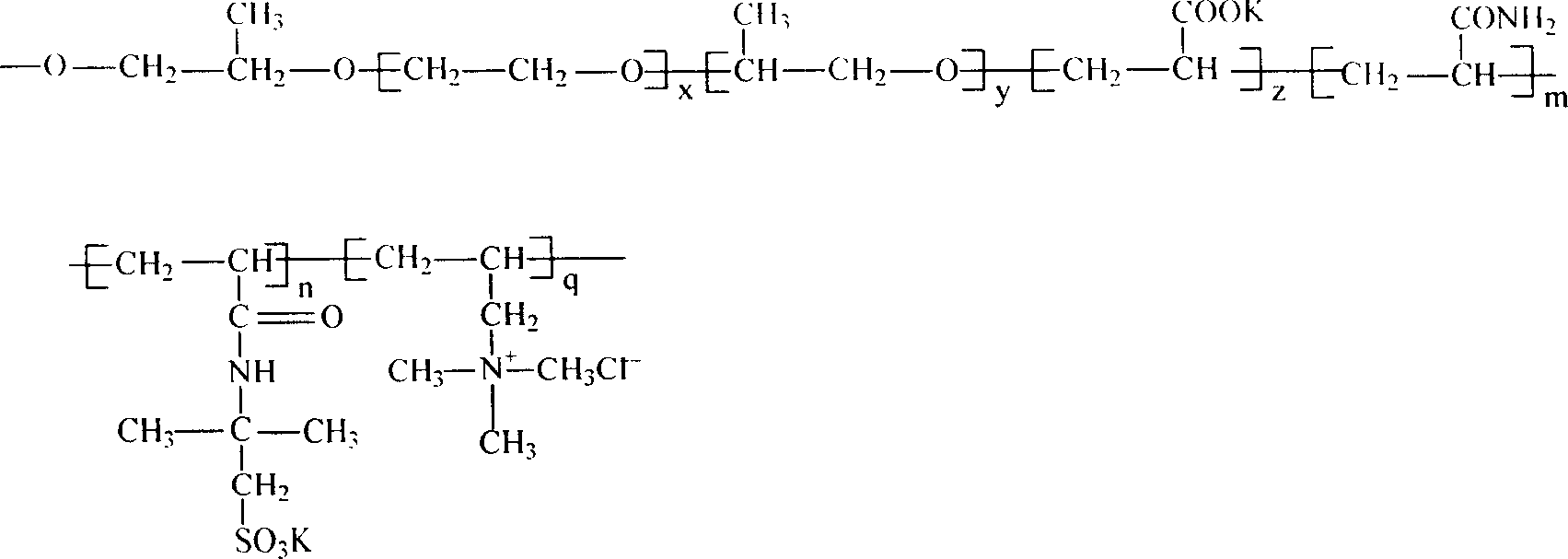

Amphoteric ion polymeric alcohol for drilling fluid and its preparation method

A zwitterion and drilling fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of drilling fluid viscosity increase, and achieve the effect of inhibiting hydration and good anti-slump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1. Add 50 g of acrylic acid, 165 g of acrylamide, 95 g of 2-acrylamido-2-methylpropanesulfonic acid, 45 g of allyl trimethyl ammonium chloride, 750 g of ethylene oxide and cyclohexane to the polymerization reactor. Oxypropane 1650g, initiator propylene glycol 65g, polymerization catalyst benzoyl peroxide 25g, heated to 105°C under constant stirring, the polymerization reaction started and was intense, and cooling water was introduced to adjust the reaction temperature.

[0015] Keep the reaction temperature at 120-135°C and the reaction pressure at 0.3-0.5Mpa. After 2-3h reaction, cooling water is introduced to cool to 70-80°C. The polymer is slowly added to another reaction vessel, and this reaction vessel has a pre-prepared concentration of 20% (mass percent) potassium hydroxide solution, and the neutralization reaction is exothermic, and the temperature of the reactor is controlled at 80 °C by cooling water. -90°C, when the pH of the solution is 7-8, 6850 g o...

Embodiment 2

[0016] Example 2. Add 65g of methacrylic acid, 145g of acrylamide, 100g of 2-acrylamido-2-methylpropanesulfonic acid, 37g of allyltrimethylammonium chloride, and 900g of ethylene oxide to the polymerization reactor and propylene oxide 1600g, initiator glycerol 73g, polymerization catalyst benzoyl peroxide 22g, heated to 105 ℃ under constant stirring, the polymerization reaction started, the reaction temperature was adjusted by cooling water, and the temperature was controlled at 110-140 ℃ Within the range, the reaction pressure is 0.2-0.6MPa, and after 2-3h reaction, it is cooled to 70-80 ℃ by cooling water. A polymer was slowly added to a reaction vessel with a concentration of 20% (mass percent) potassium hydroxide solution to carry out neutralization reaction, and the reaction temperature was controlled at 80-90°C. When the pH of the solution is 7-8, the neutralization reaction is completed, and 7400 g of zwitterionic polymer alcohol for drilling fluid with a concentration ...

Embodiment 3

[0017] Example 3. Drilling fluid rheological test

[0018] The fresh water base slurry used in the test is 4% anqiu sodium bentonite, and the salt water base slurry is 10% anqiu sodium bentonite added to a 4% NaCl aqueous solution.

[0019] strip

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com