Exterior thermal-insulating composite layer for external wall and external wall exterior insulation system using same

It is a technology of external wall thermal insulation and thermal insulation composite, which is applied in thermal insulation, wall, climate change adaptation and other directions, which can solve the problems of fire hazards, material thermal resistance decline, poor combustion performance, etc., to reduce noise pollution, stable thermal resistance performance, The effect of improving the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

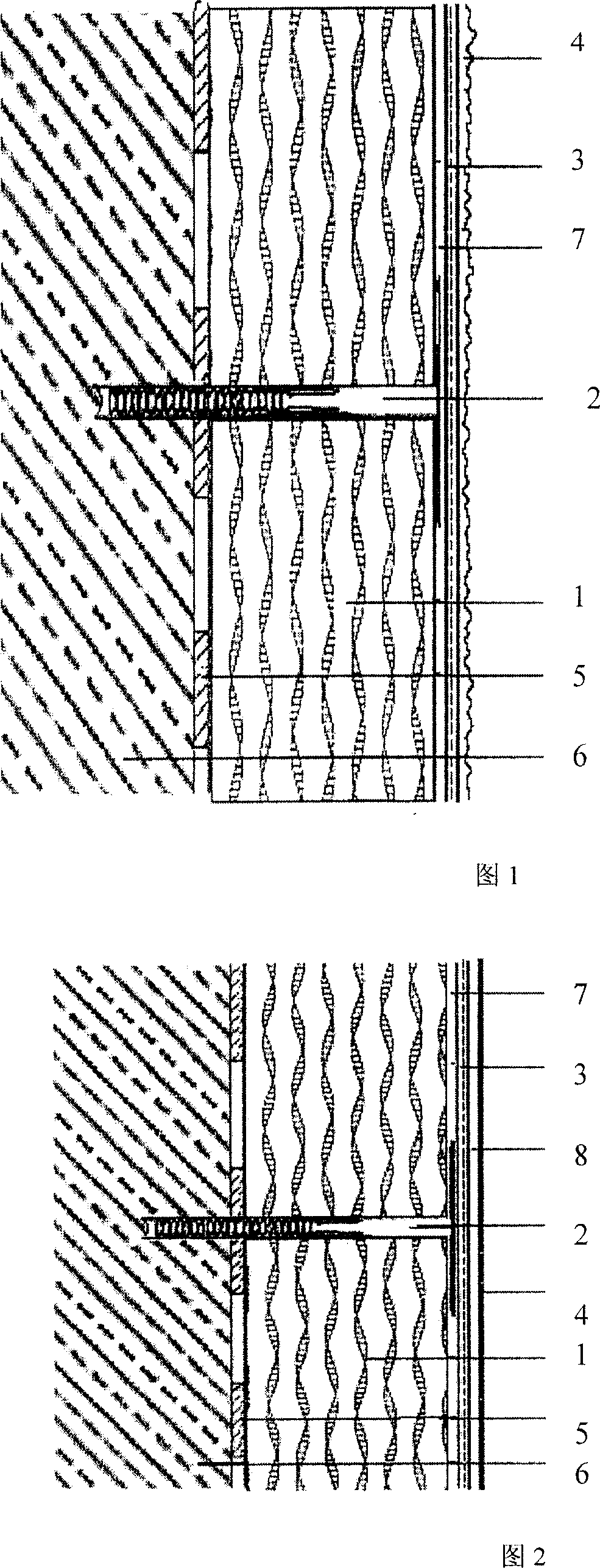

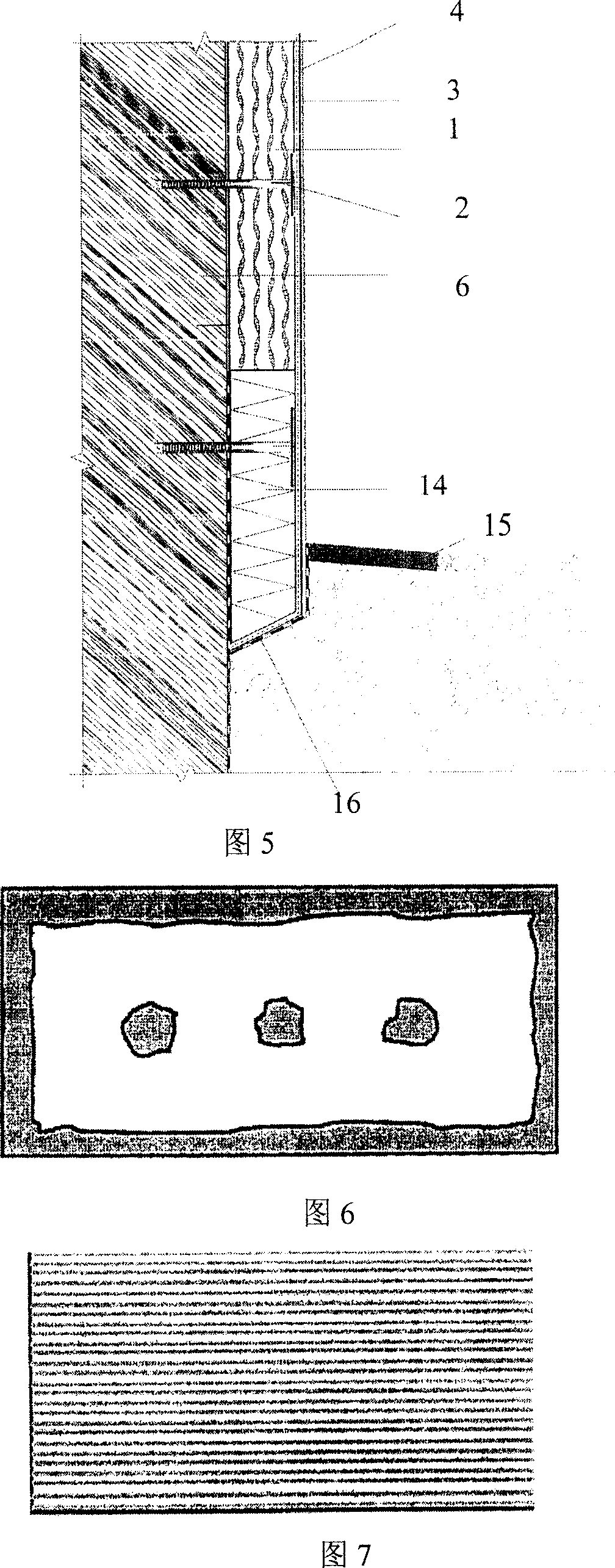

[0031] Example 1: As shown in Figure 1, it is an exterior wall thermal insulation composite layer with a mortar facing layer, which includes mineral wool board 1, anchor 2, glass fiber mesh cloth 3 and facing layer 4, mineral wool board 1 Adhere to the outer wall 6 through the bonding mortar 5, and the anchor for reinforcement 2 penetrates the mineral wool board 1 and inserts into the outer wall 6, in order to flatten the installation surface, first coat the outer side of the mineral wool board There is a leveling layer 7, the glass fiber mesh cloth 3 is used as a reinforcement layer to cover the leveling layer 7, and the silicone resin paint is sprayed on the outside of the glass fiber mesh cloth 3 as the facing layer 4. Of course, other mortar materials known in the art can also be used as the finishing layer and sprayed on the outermost layer.

Embodiment 2

[0032] Example 2: As shown in Fig. 2, it is an exterior wall external thermal insulation composite layer with the finishing layer 4 being a plane. The difference from Example 1 is that a putty leveling layer 8 is added outside the glass fiber mesh cloth 3. The silicone resin paint is applied to the outermost layer. Of course, other paints known in the art can also be used as the finishing layer to be applied to the outermost layer.

Embodiment 3

[0033] Example 3: As shown in Figure 3, it is an exterior wall external thermal insulation composite layer where the finishing layer 4 is a ceramic tile. The difference from Embodiment 2 is that the outermost finishing layer 4 is replaced by a ceramic tile. The binding agent 9 is adhered to the glass fiber mesh cloth 3, and the gaps between the tiles are filled with the tile grout 10.

[0034] The mineral wool board 1 in the above three embodiments can be rock wool board, slag wool board or glass wool board, or other types of mineral wool board.

[0035] The following describes in detail the construction process of the external wall thermal insulation composite layer and its system:

[0036] 1. The base wall and its pretreatment

[0037] 1.1 Treatment method of concrete base layer (see Table 2)

[0038] Table 2

[0039] Base wall

Approach

Types of

live situation

Concrete, precast mixed

Concrete components, tape coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com