Lifting device for lifting heavy

A technology for heavy objects and containing devices, which is applied in the direction of lifting devices, measuring devices, lifting frames, etc., to achieve the effect of continuous and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

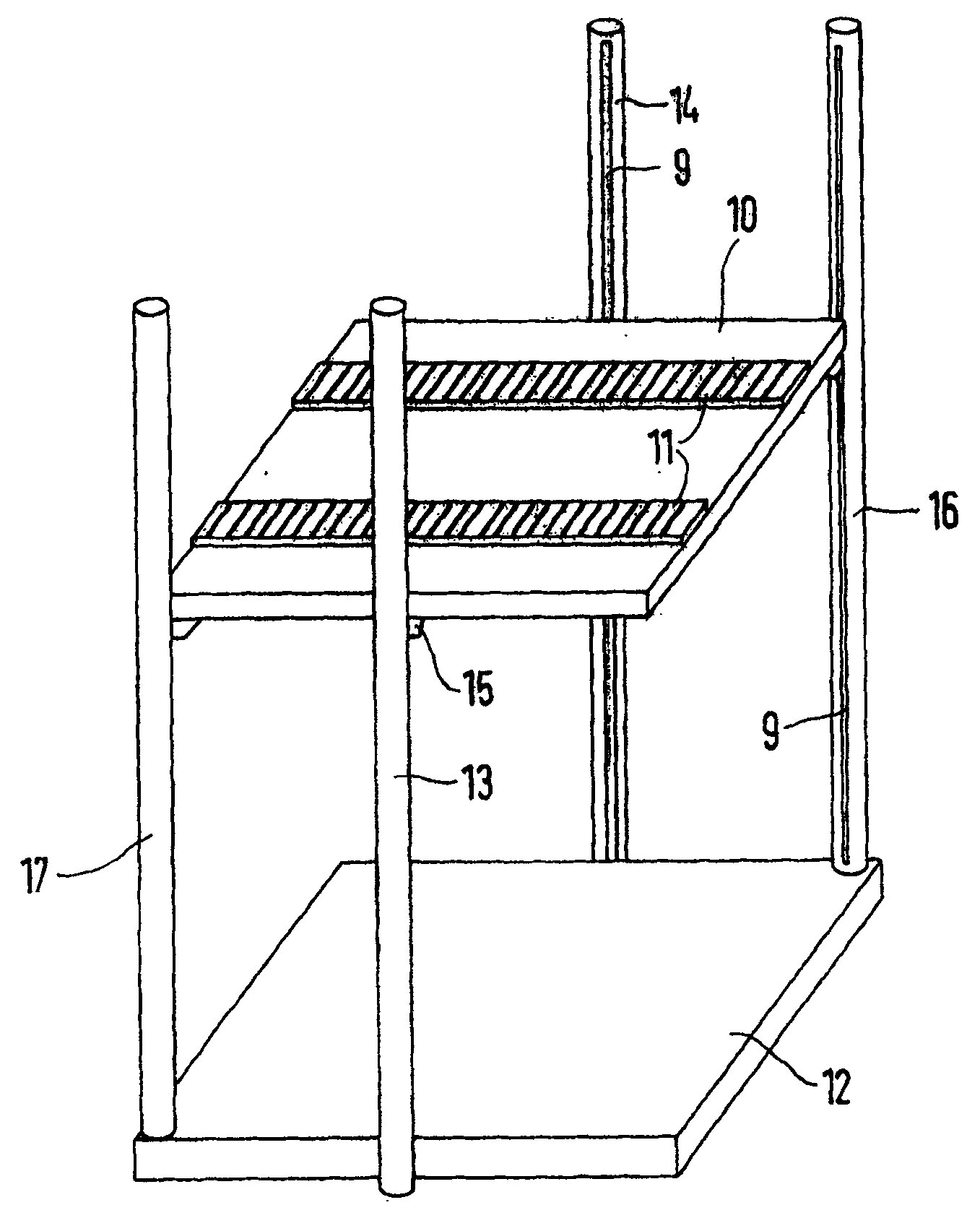

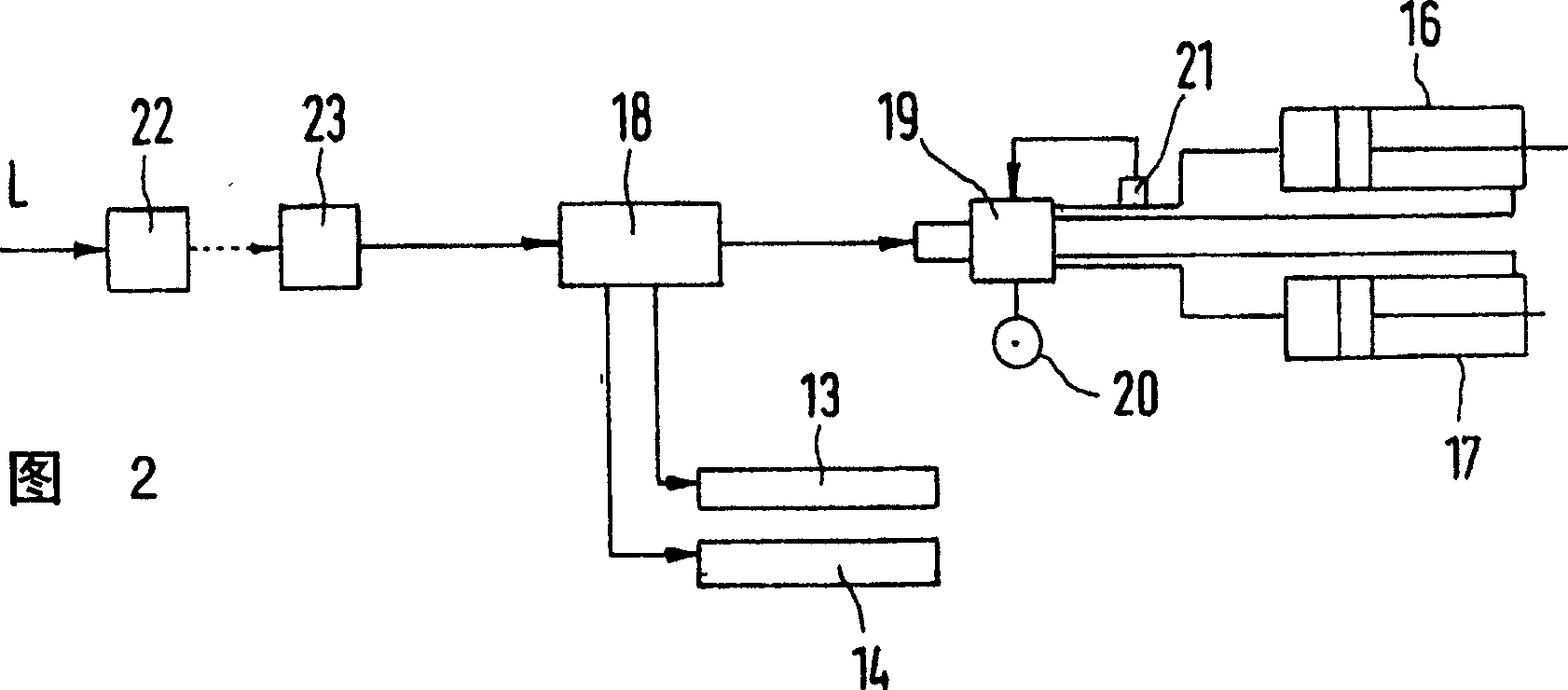

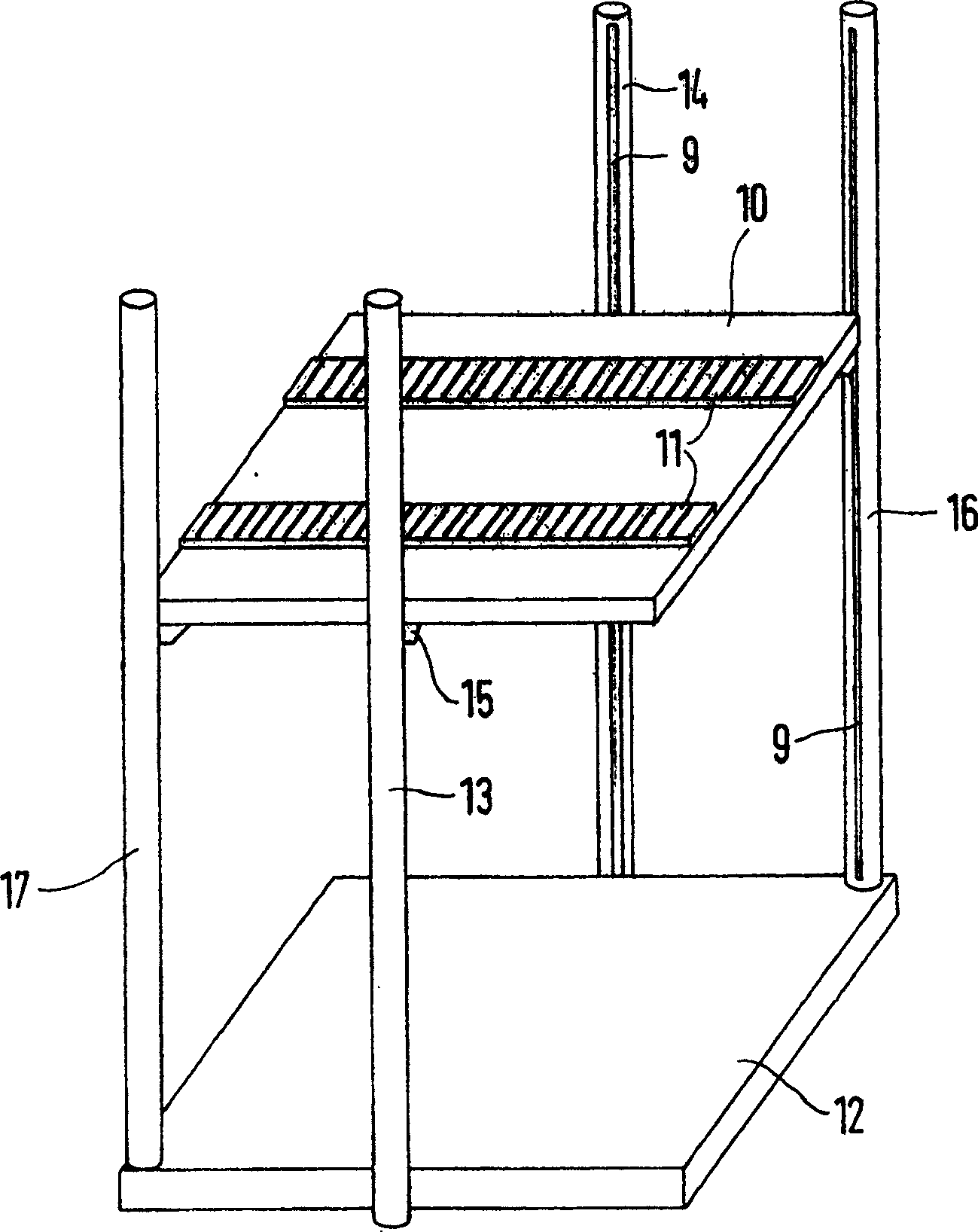

[0019] exist figure 1 The lifting device described in as an embodiment of the invention is used for lifting and lowering of heavy objects. Each weight is placed on a lifting table 10 as a weight receiving device, where two raceways 11 mounted on the lifting table 10 work. Instead of the raceway 11, other devices can also be used for the slight movement of the weight, such as air-cushion guides, sliding rails, rolling rails or transport equipment, all conceivable things in the simplest case.

[0020] On a plate-shaped base 12, two vertical linear drive devices 13, 14 are installed centrally on opposite sides of the base 12, which can also be frame-shaped or have another basic support. These are, for example, electric or hydraulic linear drives 13 , 14 . From the longitudinal slots 9 of the linear drives 13 , 14 protrude a drive element 15 , only one of which can be seen in this perspective view. The drive 15 is provided on the respective drive element of the linear drive 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com