Method for improving sealing performance of valve of cylinder head and valve potted line move-up detector

A sealing line and sealing technology, which is applied in the direction of engine components, engine testing, machine/engine, etc., can solve the problems of low production efficiency, high labor intensity, inspection of valve sealing line beating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

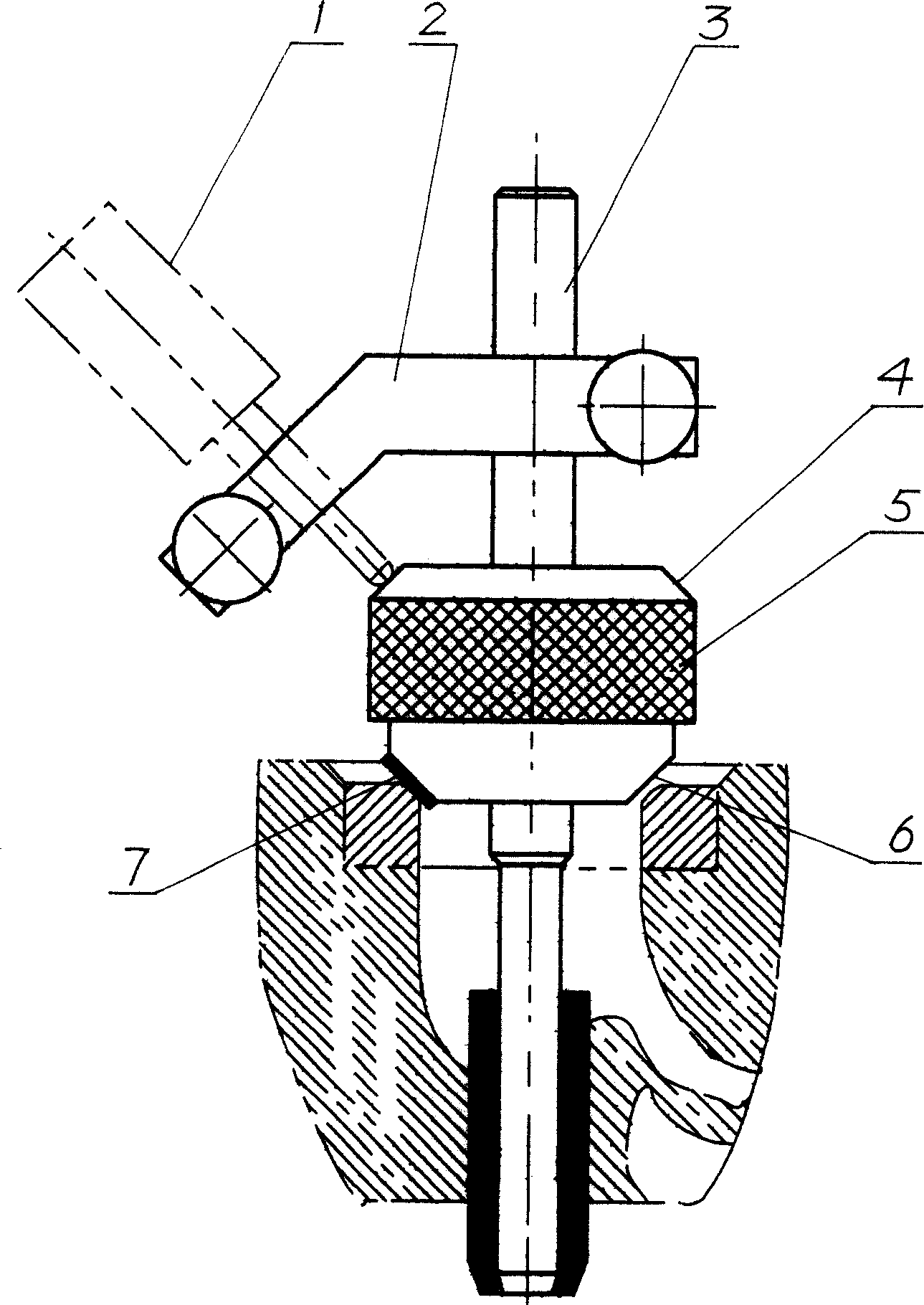

[0011] Below by embodiment and in conjunction with accompanying drawing, further illustrate the method of the present invention and used checker:

[0012] Carry out conventional mechanical processing on the cylinder head valve first, and then use the valve seal line runout inspection tool to detect the runout of the valve seal line. If the runout is out of tolerance, further reaming and rolling are performed on the valve until it fully meets the requirements.

[0013] The inspection tools used are shown in the accompanying drawings. In the middle of the mandrel 3, there is a detection block 5 that is in sliding fit with the mandrel. The upper and lower ends of the detection block have conical surfaces 4 and 6. The angles between the two conical surfaces and the valve sealing line are the same. The lower conical surface 6 is inlaid with a cemented carbide block 7 that is higher than the conical surface. The protruding part of the alloy block is in the shape of a knife edge and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com