Gas low temperature heat exchanger capable of self eliminating stress and pollution proof

A low-temperature heat and heat exchanger technology, applied in low-temperature engineering and low-temperature fields, can solve the problems of not considering the influence of thermal expansion and cold-contraction heat exchanger sealing performance, failing to meet the requirements of anti-pollution and self-stress relief, and achieve remarkable results. Economic and social benefits, strong corrosion resistance, smooth inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

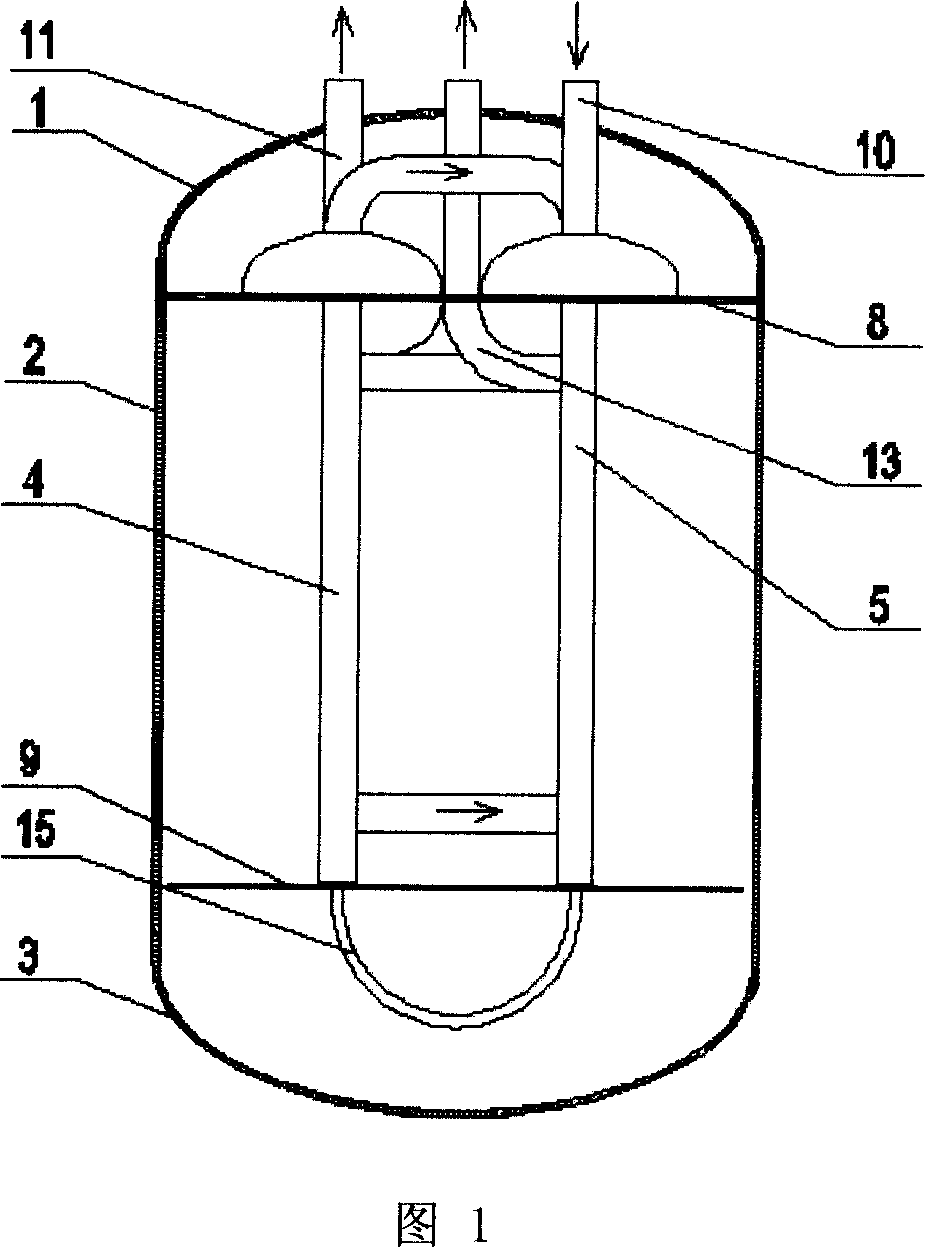

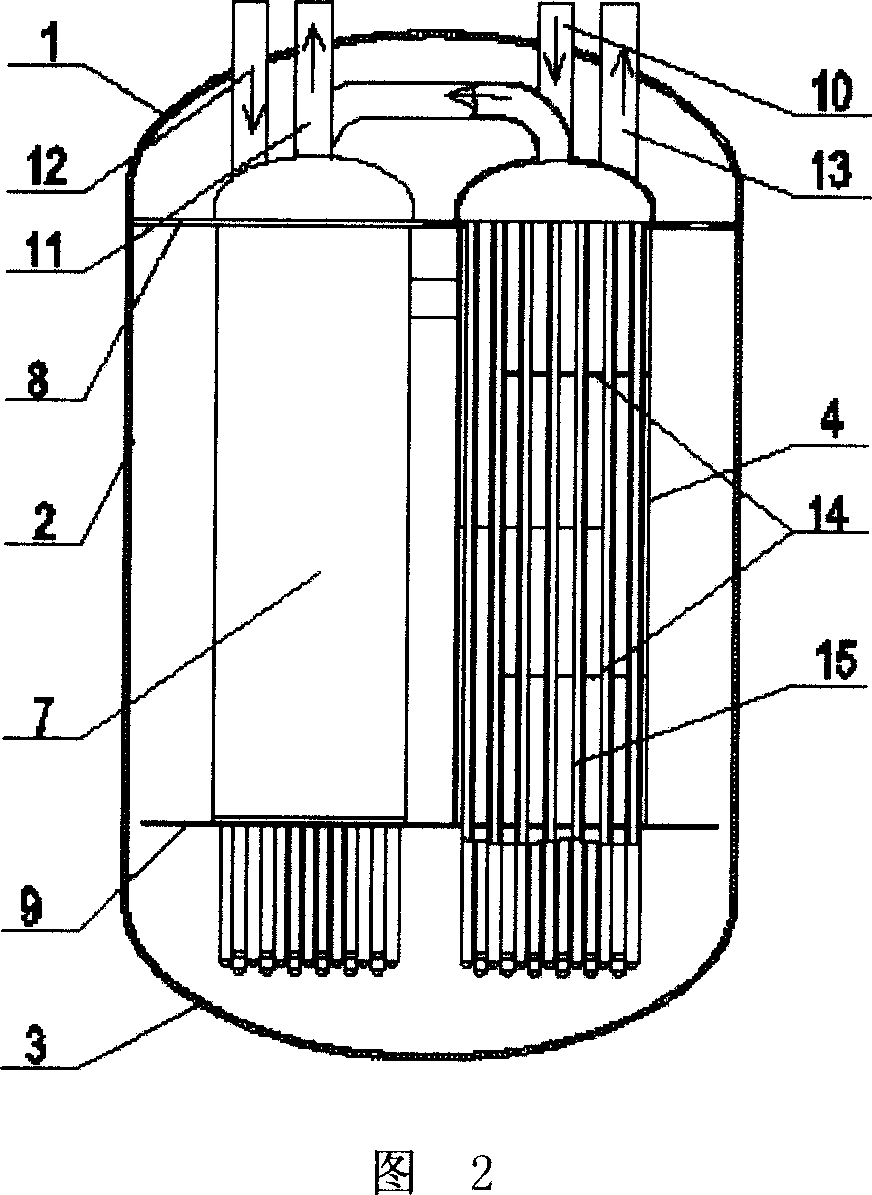

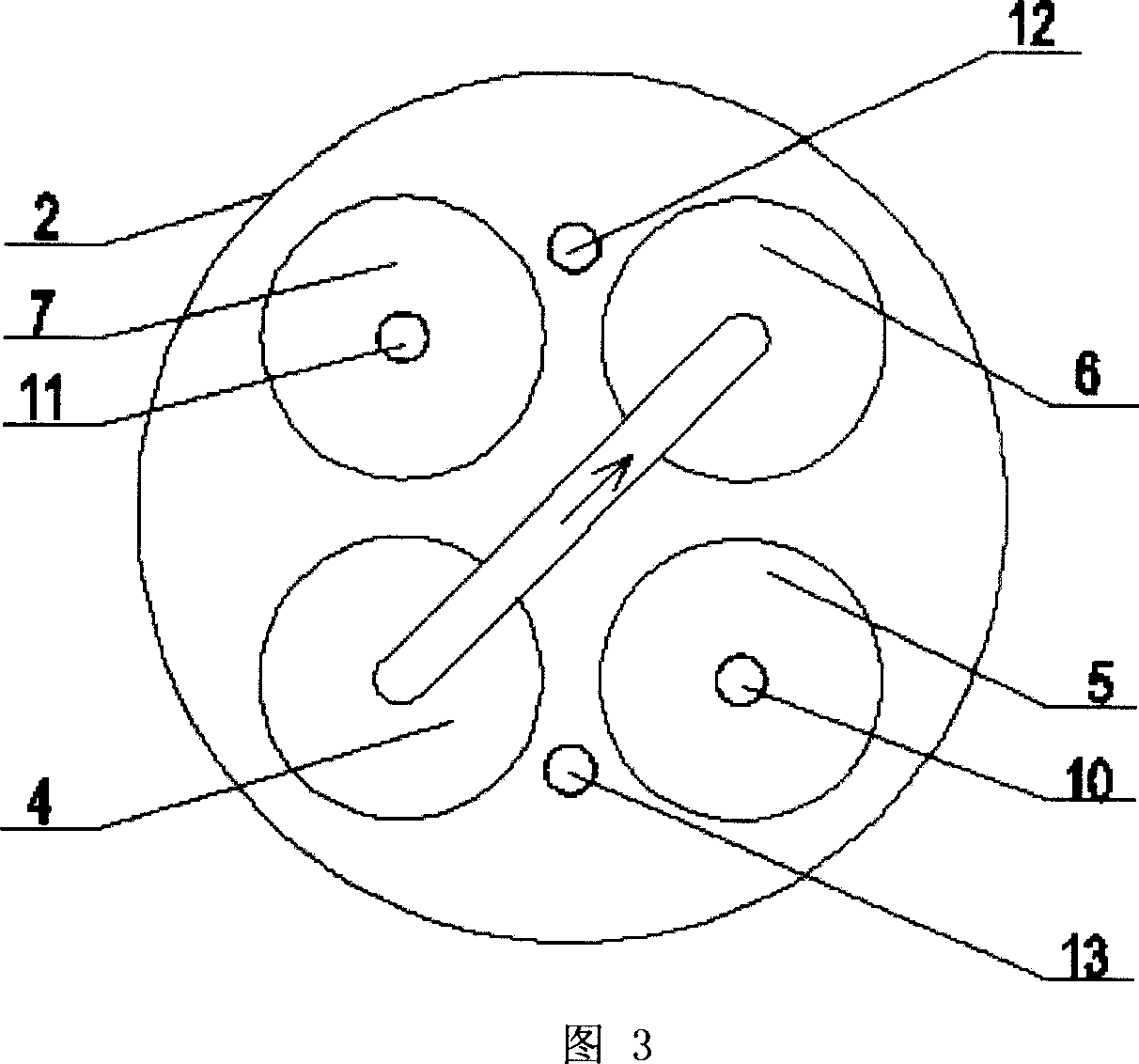

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention comprises a low-temperature heat exchanger upper head 1, a low-temperature heat exchanger cylinder 2, a low-temperature heat exchanger lower head 3, and a shell-and-tube heat exchange 4, B shell-and-tube heat exchanger 5, C shell-and-tube heat exchanger 6, D shell-and-tube heat exchanger 7, tube plate 8, support plate 9, low-temperature heat exchanger tube side inlet tube 10, low-temperature heat exchanger The tube-side outlet pipe 11 of the exchanger, the shell-side inlet pipe 12 of the low-temperature heat exchanger, and the shell-side outlet pipe 13 of the low-temperature heat exchanger. The tube sheet 8 is located at the upper end of the low-temperature heat exchanger shell 2, and the upper end of the low-temperature heat exchanger head 1 and the upper end of the low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com