Preparation method of wheat germ agglutinin and its application in inhibiting mammary gland cancer activity

A wheat germ agglutinin and wheat germ technology, which is applied in the preparation methods of peptides, chemical instruments and methods, and medical preparations containing active ingredients, etc., to achieve the effects of scientific and reasonable process design, no environmental pollution, and improved utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

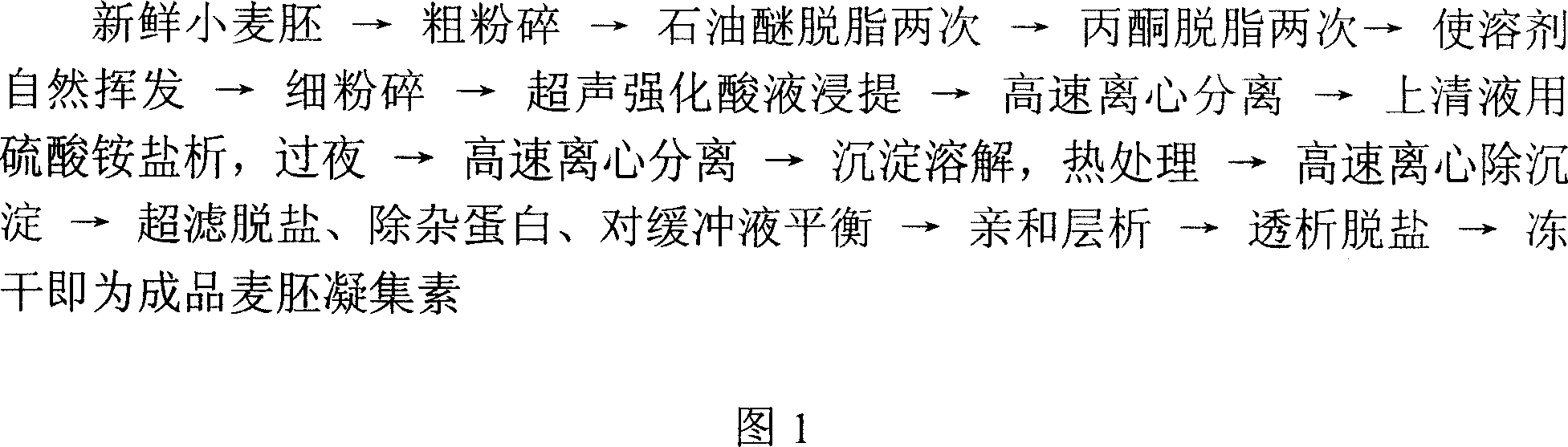

[0030] Take 500g of fresh wheat germ, grind it through a 20-mesh sieve, degrease with 2L of pre-cooled petroleum ether (bp 40-60°C) twice, and degrease with 2L of pre-cooled acetone twice, and let the solvent evaporate naturally at room temperature until the smell disappears. After grinding, pass through a 60-mesh sieve, use 9 times 0.5M formic acid solution, ultrasonic intensity 30W / cm2, stir and extract at room temperature for 0.5h, and then centrifuge at 4°C, 25000g for 20min. The supernatant was salted out with 40% saturation of ammonium sulfate, overnight at 4°C, and centrifuged at 25000g for 20min at 4°C. The precipitate was dissolved in 500 mL of water, heat-treated at 65°C for 10 minutes, centrifuged at 25,000 g for 20 minutes at 4°C, and the precipitate was removed to obtain the supernatant. Ultrafiltration of the supernatant: first use a hollow fiber ultrafiltration tube with a molecular cut-off value of 50kD of 2.5cm×20cm for ultrafiltration, and the ultrafiltration...

Embodiment 2

[0032] Take 500g of fresh wheat germ, grind it through a 20-mesh sieve, degrease with 2L of pre-cooled petroleum ether (bp 40-60°C) twice, and degrease with 2L of pre-cooled acetone twice, and let the solvent evaporate naturally at room temperature until the smell disappears. After grinding, pass through a 60-mesh sieve, use 11 times 0.3M formic acid solution, ultrasonic intensity 30W / cm2, stir and extract at room temperature for 1.5h, and then centrifuge at 4°C and 25000g for 20min. The supernatant was salted out with 40% saturation of ammonium sulfate, overnight at 4°C, and centrifuged at 25000g for 20min at 4°C. The precipitate was dissolved in 500 mL of water, heat-treated at 65°C for 10 minutes, centrifuged at 25,000 g for 20 minutes at 4°C, and the precipitate was removed to obtain the supernatant. Ultrafiltration of the supernatant: first use a hollow fiber ultrafiltration tube with a molecular cut-off value of 50kD of 2.5cm×20cm for ultrafiltration, and the ultrafiltra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com