Dielectric barrier discharge excimer light source

A dielectric barrier and excimer technology, applied in discharge lamps, circuits, lasers, etc., can solve problems such as voltage increase and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

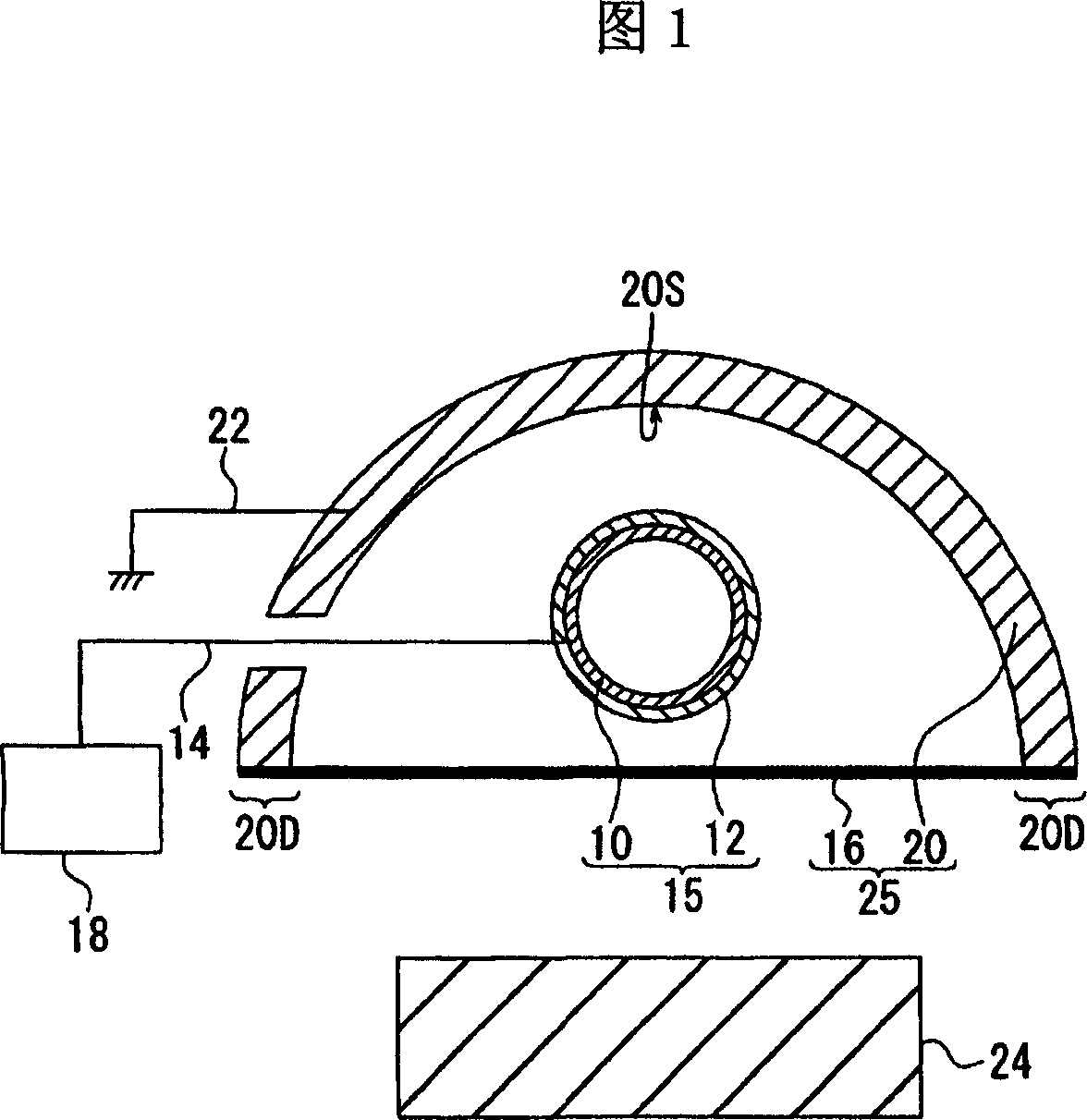

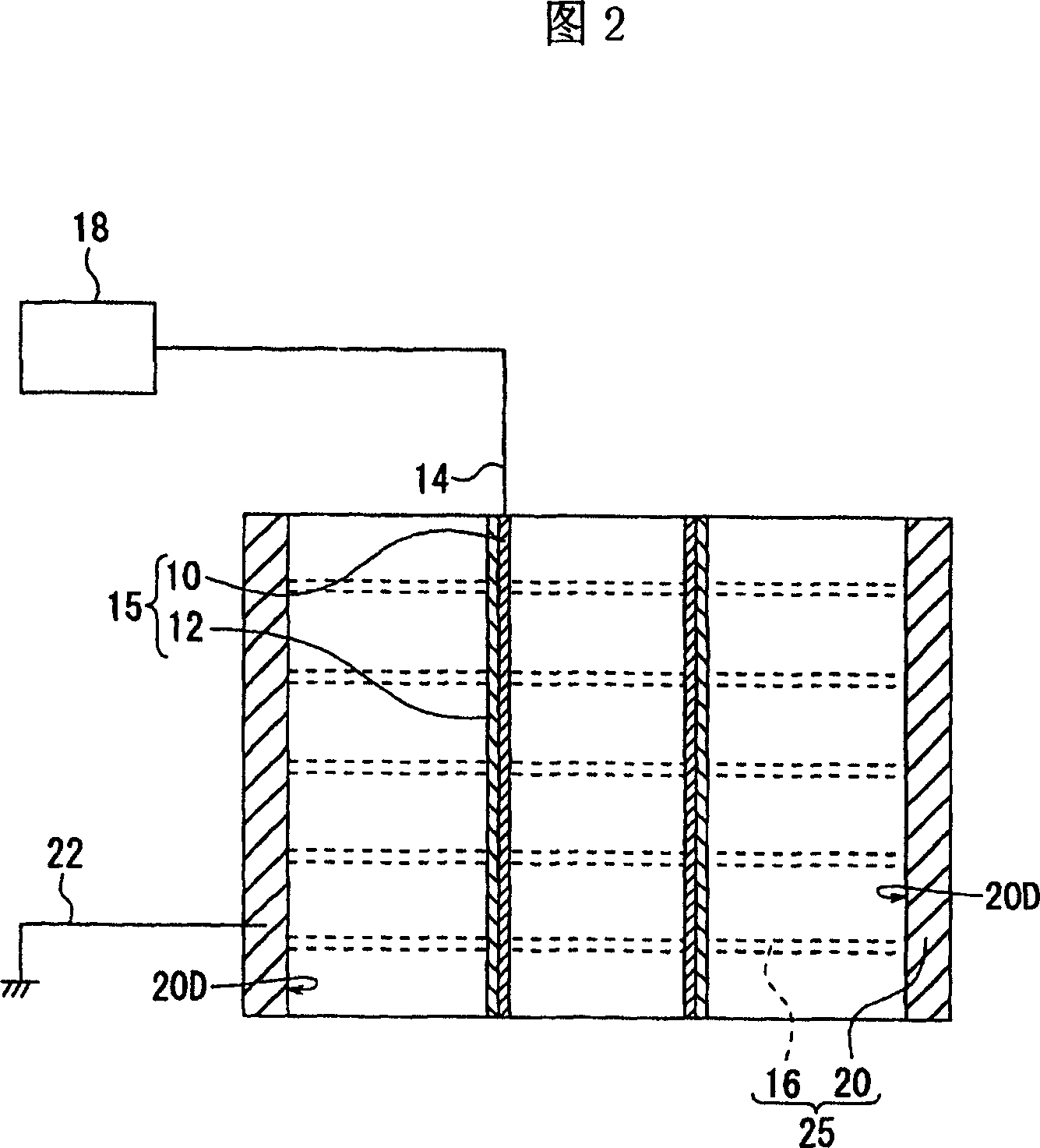

[0101] The structure and working principle of the first dielectric barrier discharge excimer light source of the present invention will be described with reference to FIG. 1 and FIG. 2 . Fig. 1 is a schematic cross-sectional view obtained by cutting along the longitudinal direction perpendicular to the anode of the first dielectric barrier discharge excimer light source. Fig. 2 is a schematic longitudinal sectional view obtained by cutting along the longitudinal direction parallel to the anode of the first dielectric barrier discharge excimer light source.

[0102] The anode electrode 10 consists of a straight and long cylinder covered with a dielectric 12 at the periphery of the cylinder. The anode 15 has an anode electrode 10 and a dielectric 12 . In the following description, a structure composed of an anode electrode and a dielectric is also referred to as an anode structure.

[0103] The cathode 25 has a straight semi-cylindrical cathode portion 20 and a cathode wire gr...

no. 2 example

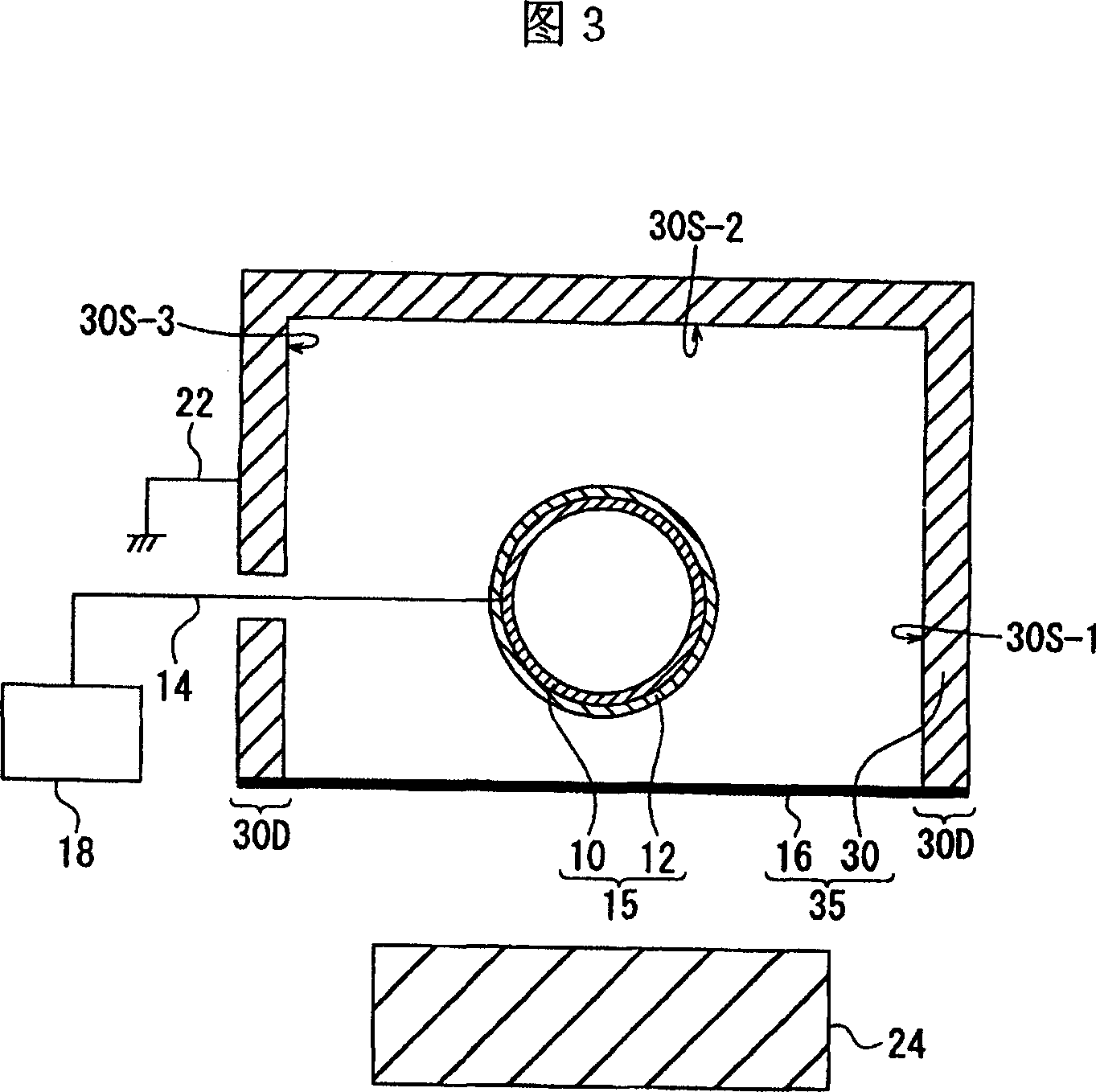

[0117] The structure of the second dielectric barrier discharge excimer light source of the present invention will be described with reference to FIG. 3 . Fig. 3 is a schematic cross-sectional view obtained by cutting along the longitudinal direction perpendicular to the anode of the second dielectric barrier discharge excimer light source. A schematic longitudinal sectional view taken along a longitudinal direction parallel to the anode is omitted since it is the same as that in FIG. 2 . In the following description, in principle, only the cross-sectional view of the light source is shown, and the vertical cross-sectional view that is the same as that in FIG. 2 is omitted unless otherwise necessary.

[0118] The second dielectric barrier discharge excimer light source has the same characteristics as the above-mentioned first dielectric barrier discharge excimer light source, that is, there is an anode electrode 10 made of a hollow straight long cylinder covered with a dielect...

no. 3 example

[0121] The structure of the third dielectric barrier discharge excimer light source of the present invention will be described with reference to FIG. 4 . Fig. 4 is a schematic cross-sectional view of a third dielectric barrier discharge excimer light source cut along a longitudinal direction perpendicular to the anode. A schematic longitudinal sectional view taken along a longitudinal direction parallel to the anode is omitted since it is the same as that in FIG. 2 .

[0122] The third dielectric barrier discharge excimer light source has the same characteristics as the above-mentioned first dielectric barrier discharge excimer light source, that is, it has an anode electrode 40 made of a straight long cylinder covered with a dielectric, and contains the anode electrode 40 The elongated cathode portion 30. However, the shape of the anode electrode 40 is different from that of the cathode portion 30 . The anode electrode 40 is covered with a dielectric 42 and is a straight pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com