Packing structure with stacking platform

A packaging structure and platform technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as cracking of the sealant, crushing of the connected line, and reducing the production qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

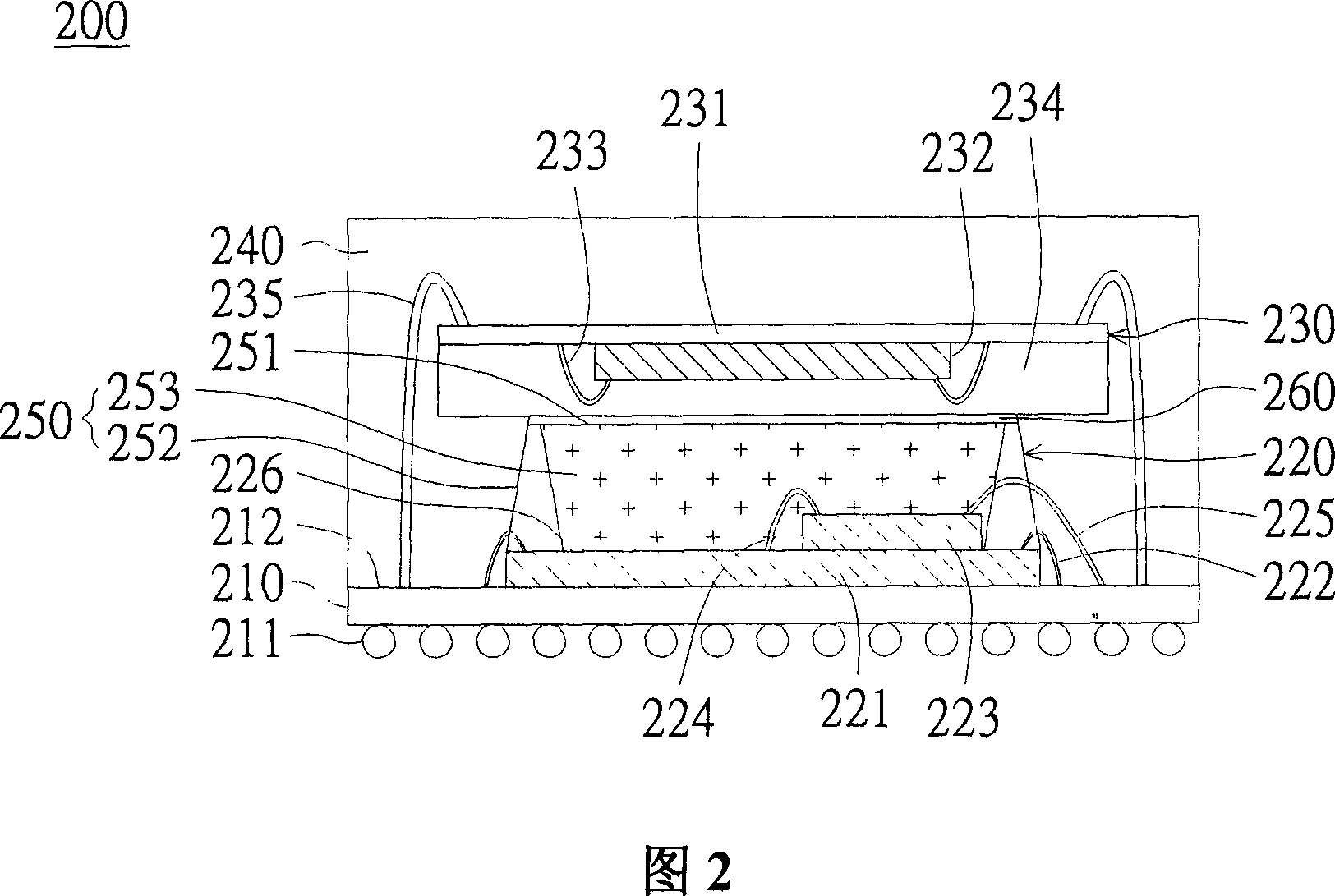

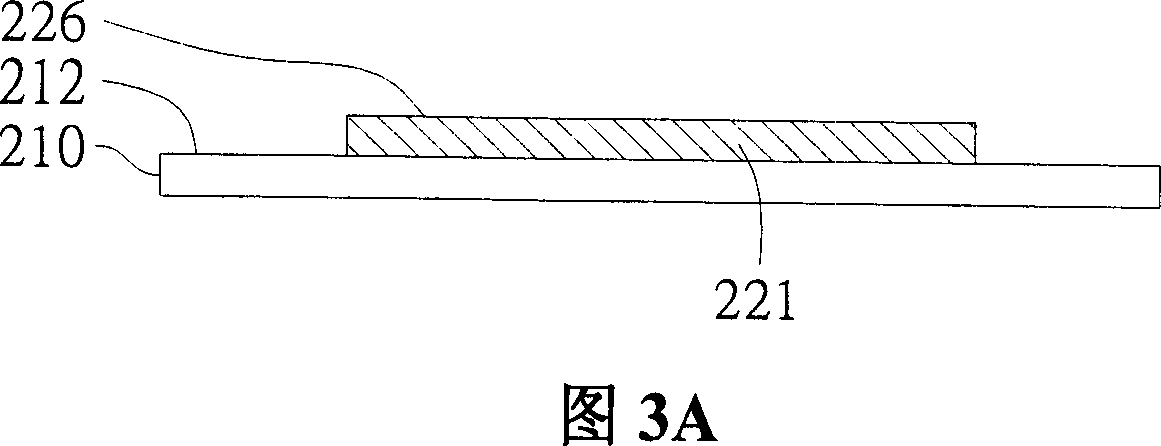

[0029] Please refer to FIG. 2 , which is a side view of a package structure according to the first embodiment of the present invention. The package structure 200 includes a substrate 210 , a first package 220 , a second package 230 and a sealant 240 . The first package 220 includes a chip 221 , a chip 223 and a liquid sealant 250 . The chip 221 is disposed on the substrate 210 and is electrically connected to the substrate 210 through gold wires 222 . The chip 223 is disposed above the chip 221 and is electrically connected to the chip 221 and the substrate 210 by gold wires 224 and gold wires 225 respectively.

[0030] The second package 230 is disposed on the platform 251 formed on the surface of the liquid encapsulant 250 . The second package 230 includes a substrate 231 and a chip 232 , the chip 232 is disposed on the substrate 231 and is electrically connected to the substrate 231 by gold wires 233 , and the second package 230 is electrically connected to the substrate 2...

Embodiment 2

[0038]Please refer to FIG. 4 , which is a side view of the package structure of the second embodiment of the present invention. The main difference between the package structure 300 of the present embodiment and the package structure 200 of the first embodiment lies in the portion where the liquid sealant contacts the substrate. The liquid encapsulant 350 of this embodiment not only completely covers the surface 326 of the chip 321 , but also partially covers the surface 312 of the substrate 310 . The method of forming the liquid encapsulant 350 is, for example, to firstly form a dam structure 352 on the surface 312 of the substrate 310 , and the dam structure 352 is located at the periphery of a certain distance from the chip 321 . After that, the glue 353 is filled into the accommodation space surrounded by the dam 352 to form the liquid sealant 350 covering part of the surface 312 of the substrate 310 and the surface 326 of the chip 321 . The connection relationship and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com