Inductive coupling source

A technology of inductive coupling and inductively coupled coils, which is applied in the field of microelectronics, can solve problems such as excessive inductance, increased inhomogeneity of radial plasma density, and unstable impedance matching, so as to achieve uniform magnetic field strength, reduce dependence, The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the inductive coupling source of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not used to limit the protection scope of the present invention.

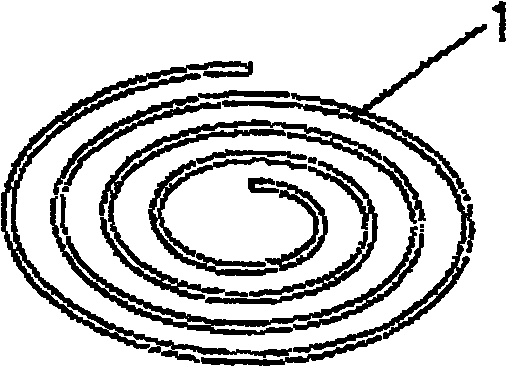

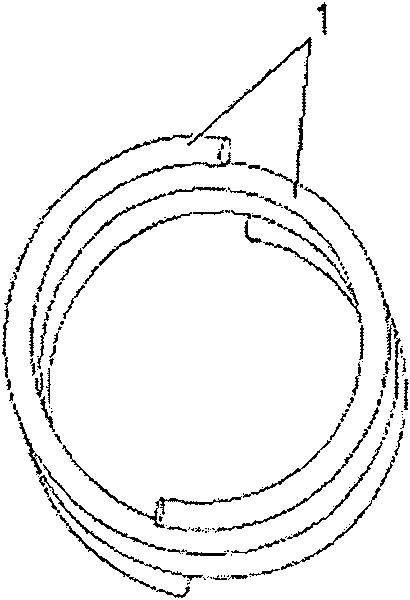

[0028] see Figure 2 to Figure 4 . The structure of the first embodiment of the inductively coupled source of the present invention includes a pair of inductively coupled coils 1 and excitation sources that are nested and arranged in complete symmetry. The inductively coupled coil is an involute multi-turn three-dimensional coil. The excitation source is a radio frequency power source.

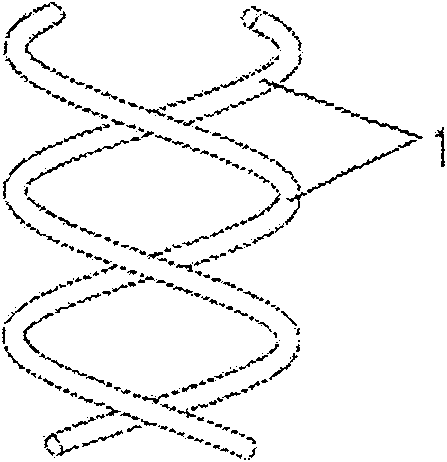

[0029] see Figure 5 . The structure of the second embodiment of the inductively coupled source of the present invention includes an inner group coil 2 and an outer group coil 3 and an excitation source connected in series or in parallel, wherein the inner group coil 2 and the outer group coil 3 are each composed of a pair of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com