Aluminium gallium nitride/gallium nitride high electronic migration rate transistor and its manufacturing method

A high electron mobility, aluminum gallium nitride technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems affecting device frequency characteristics, etc. Effect of gate leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

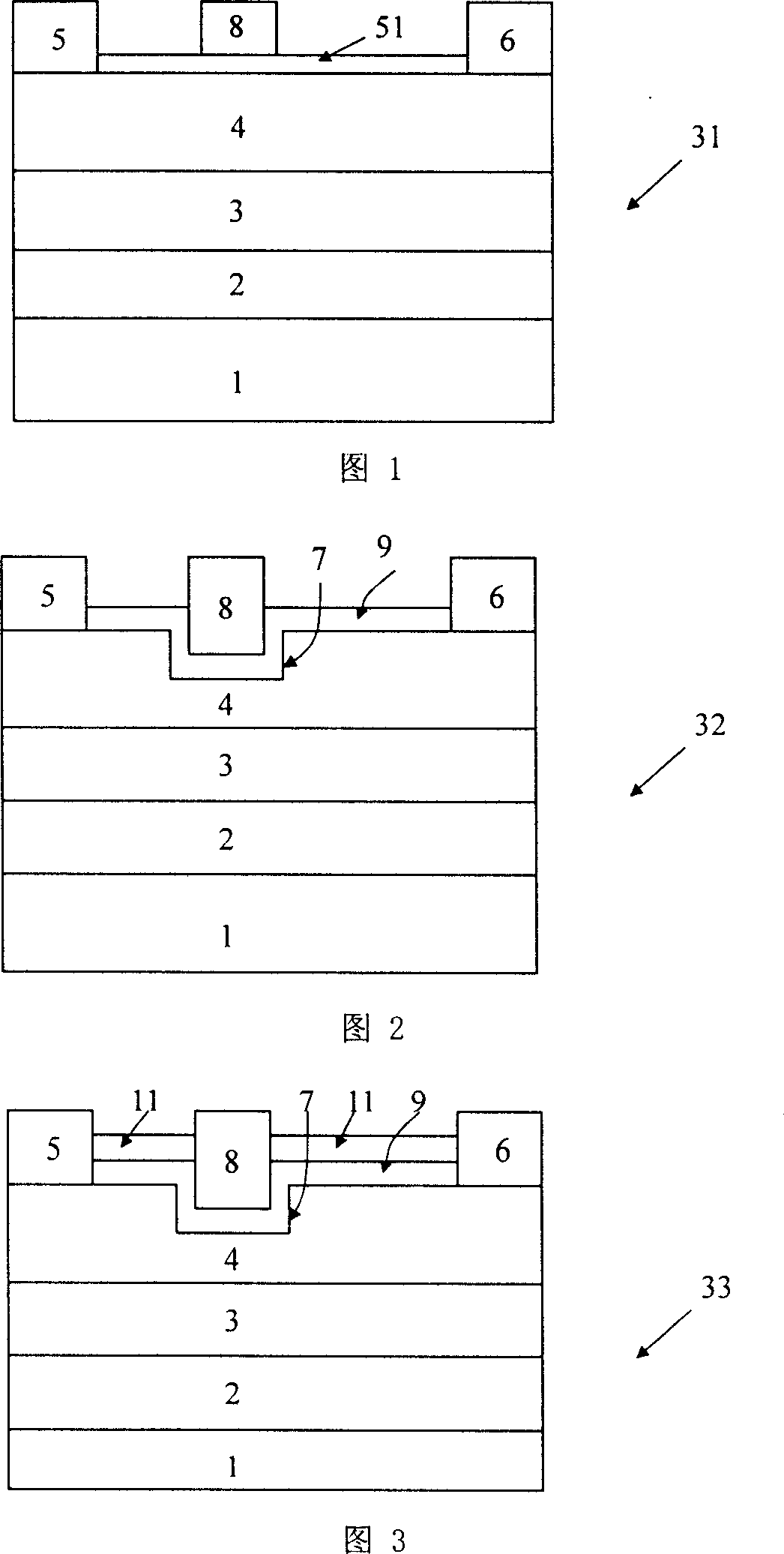

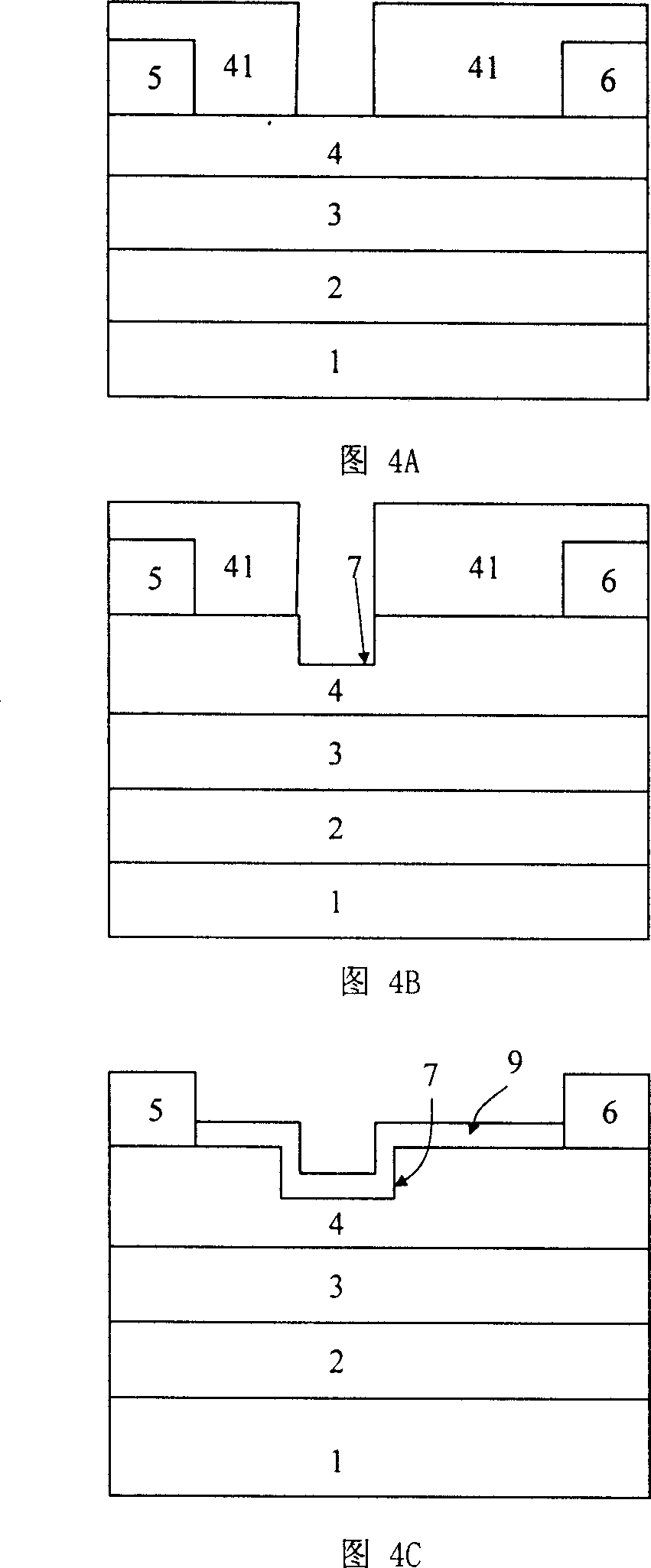

[0061] Figure 2 shows a device 32 of an embodiment of the invention. In the device 32, 1 is a substrate, 2 is a buffer layer, 3 is a GaN channel layer, and 4 is an Al X Ga 1-x N (018 cm -3 . The buffer layer 2, the channel layer 3, and the barrier layer 4 are obtained by epitaxial growth on the substrate 1 sequentially by MOCVD, RF-MBE or any other suitable growth method, and the specific growth process can refer to relevant literature.

[0062] On the barrier layer provide ohmic contact electrode 5 as source electrode, ohmic contact electrode 6 as drain electrode, source electrode 5 and drain electrode 6 can be Ti / Al / Ni / Au, Ti / Al / Mo / Au, Ti / Al / Ti / Au or any other suitable material that can form an ohmic contact with the barrier layer, the metal on the source electrode 5 and the drain electrode 6 is preferably formed by electron beam evaporation, and rapidly annealed at a high temperature of 780°C to 900°C for 30s or so, nitrogen gas is needed during the rapid annealing pro...

Embodiment 2

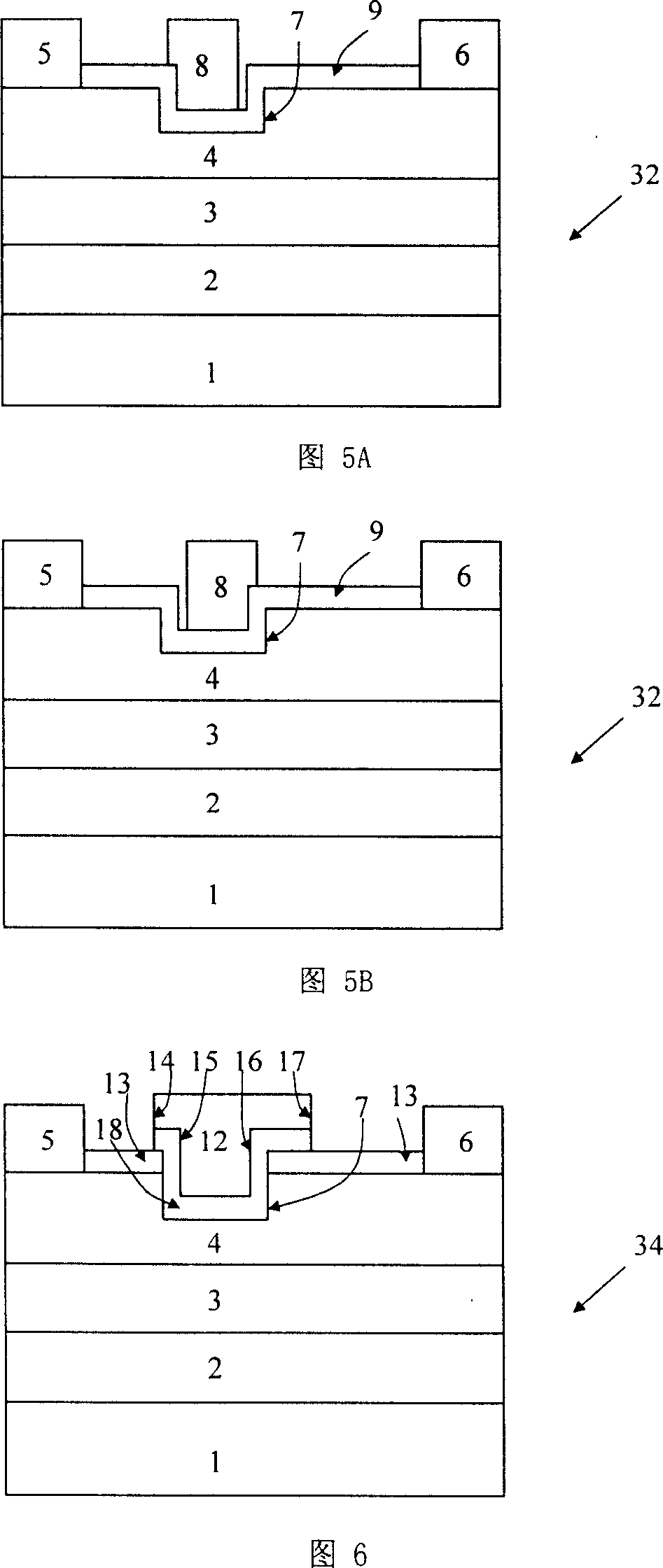

[0079] FIG. 6 is a device 34 with a "T" gate according to one embodiment of the present invention. Similar to device 32 in FIG. 2 , device 34 has substrate 1 , buffer layer 2 , GaN channel layer 3 and AlGaN barrier layer 4 . The device 34 also has a source electrode 5 and a drain electrode 6 located on the barrier layer with the device 32. The surface of the device 34 is covered by the dielectric layer 13 except for the groove 7, and the bottom and side walls of the groove are covered by the dielectric layer 18. The dielectric layer 18 extends toward the source electrode 5 and the drain electrode 6 on the surface of the device and covers the dielectric layer 13. The dielectric layer 18 exists only under the gate electrode 12, and the gate electrode 12 of the device is a "T" gate structure. The distance between sidewalls 14 and 15 in the "T"-shaped grid 12 is less than 0.5 micron, and the distance between sidewalls 16 and 17 is about 1 micron, that is, the "T"-shaped grid 12 is...

Embodiment 3

[0096] FIG. 8 shows a device 36 with a "T" gate according to another embodiment of the present invention. Same as the device in the previous embodiment, the device 36 has a substrate 1, a buffer layer 2, a GaN channel layer 3, an AlGaN barrier layer 4, a source electrode 5 and a drain electrode 6 on the barrier layer, and the surface of the device 36 except The outside of the groove 7 is covered by a dielectric layer 13, and the dielectric layer 18 not only exists under the gate metal but also covers the exposed part of the dielectric layer 13. The gate electrode 12 of the device 36 is the same as the device 34. It has a "T" gate structure . Similarly, the distance between the sidewalls 14 and 15 is less than 0.5 micron, and the distance between the sidewalls 16 and 17 is about 1 micron, so as to improve the performance of the AlGaN / GaN HEMT.

[0097] The formation of the buffer layer 2, the GaN channel layer 3, the AlGaN barrier layer 4, the source electrode 5 and the drain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com