Method for preparing up-conversion fluorescent matrix material NaYF4 nano crystal

A technology of matrix materials and nanocrystals, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of large particle size of nanoparticles, and achieve the effects of stable product quality, simple process and equipment, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

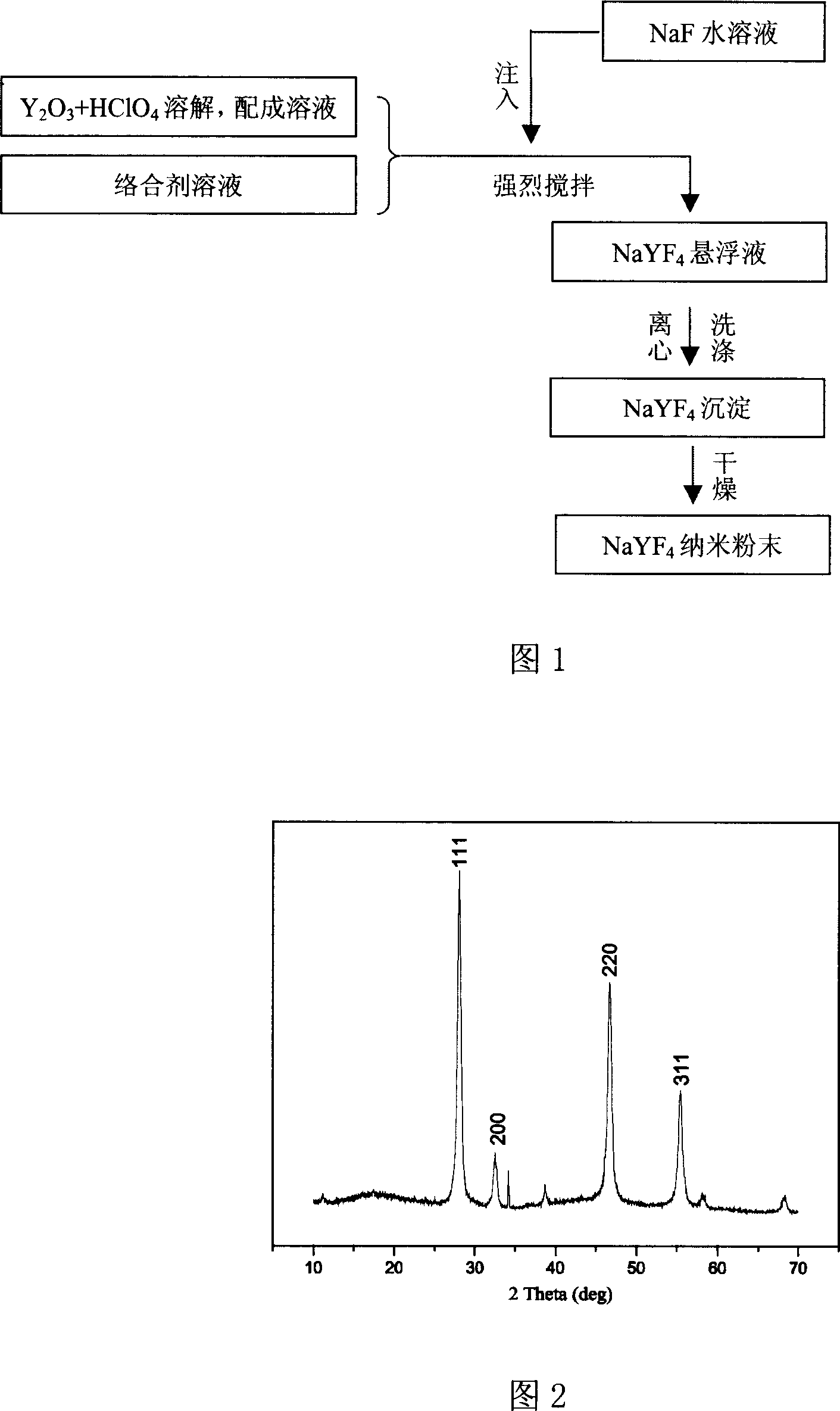

Method used

Image

Examples

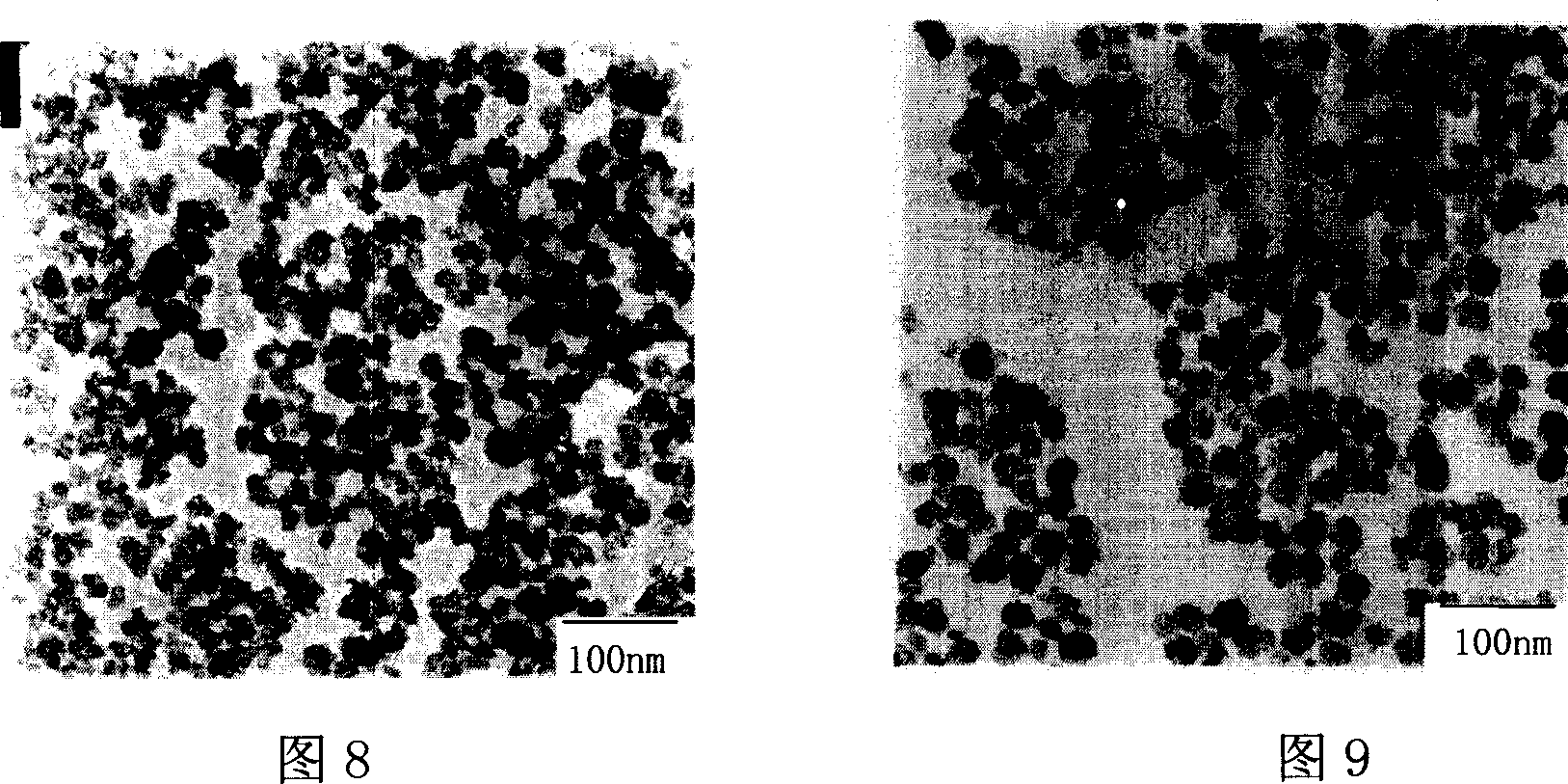

Embodiment 1

[0023] a) Weigh 0.01 mol of yttrium oxide, add a sufficient amount of perchloric acid with a concentration of 0.1 mol / l and a pH value of 6, heat and dissolve to generate 0.02 mol of yttrium perchlorate, add deionized water to make up to 100ml , be made into the yttrium perchlorate solution of 0.2mol / l, adjust its pH value to be 2;

[0024] b) preparing a 0.6mol / l trisodium citrate solution;

[0025] c) uniformly mixing the solutions of steps a) and b), wherein the molar ratio of yttrium perchlorate to trisodium citrate solution is 1:3;

[0026] d) Take another 2.1g of sodium fluoride solution, add deionized water, dissolve, adjust the pH value of the solution to 10, stir rapidly, add the solution obtained in step c) at room temperature, and age for 1 hour; the total rare earth ions and fluorine in the solution The molar ratio of sodium chloride was 1:1.2; centrifuged, washed three times with deionized water, washed once with absolute ethanol, and dried in a vacuum oven at 60...

Embodiment 2

[0028] a) Weigh 0.01mol of yttrium oxide, add a sufficient amount of hydrochloric acid with a concentration of 0.5mol / l and a pH value of 0, heat and dissolve to generate 0.02mol of yttrium chloride, add deionized water to make the volume to 100ml, and prepare into a 0.2 mol / l yttrium chloride solution, and adjust its pH to 0.

[0029] b) Prepare 0.2 mol / l trisodium citrate solution.

[0030] c) uniformly mixing the solutions of a) and b), wherein the molar ratio of trisodium citrate solution to yttrium chloride is 1:1.

[0031] d) Weigh another 2.1 g of sodium fluoride solution, add 60 ml of deionized water, dissolve, adjust the pH value of the solution to 10, stir rapidly, add to the solution obtained in step c) at 45 ° C, and age at room temperature for 5 hours; The molar ratio of total rare earth ions to sodium fluoride was 1:30; centrifuged, washed three times with deionized water and once with absolute ethanol, and dried in a vacuum oven at 30°C.

Embodiment 3

[0033] a) Weigh 0.01 mol of yttrium oxide, add a sufficient amount of perchloric acid with a concentration of 0.3 mol / l and a pH value of 4, heat and dissolve to generate 0.02 mol of yttrium perchlorate, add deionized water to dilute to 100 ml , be made into 0.2mol / l yttrium perchlorate solution, and adjust its pH value to 6.

[0034] b) Prepare 1 mol / l trisodium citrate solution.

[0035] c) Step a) is mixed with the solution of b), wherein the molar ratio of trisodium citrate solution to yttrium perchlorate is 1:5.

[0036] d) Separately weigh 2.1 g of sodium fluoride solution, add 60 ml of deionized water, dissolve, and adjust the pH value of the solution to 10. Stir quickly, add to the solution obtained in step c) at 0°C, and age at room temperature for 3 hours; the molar ratio of total rare earth ions to sodium fluoride in the solution is 1:10; centrifuge, wash with deionized water 3 times, and dry Wash once with ethanol and dry in a vacuum oven at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com