Low-temperature chip direct bonding method

A wafer bonding and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., which can solve problems such as advanced experimental conditions and high environmental dependence, stress and debonding problems that cannot be ignored, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

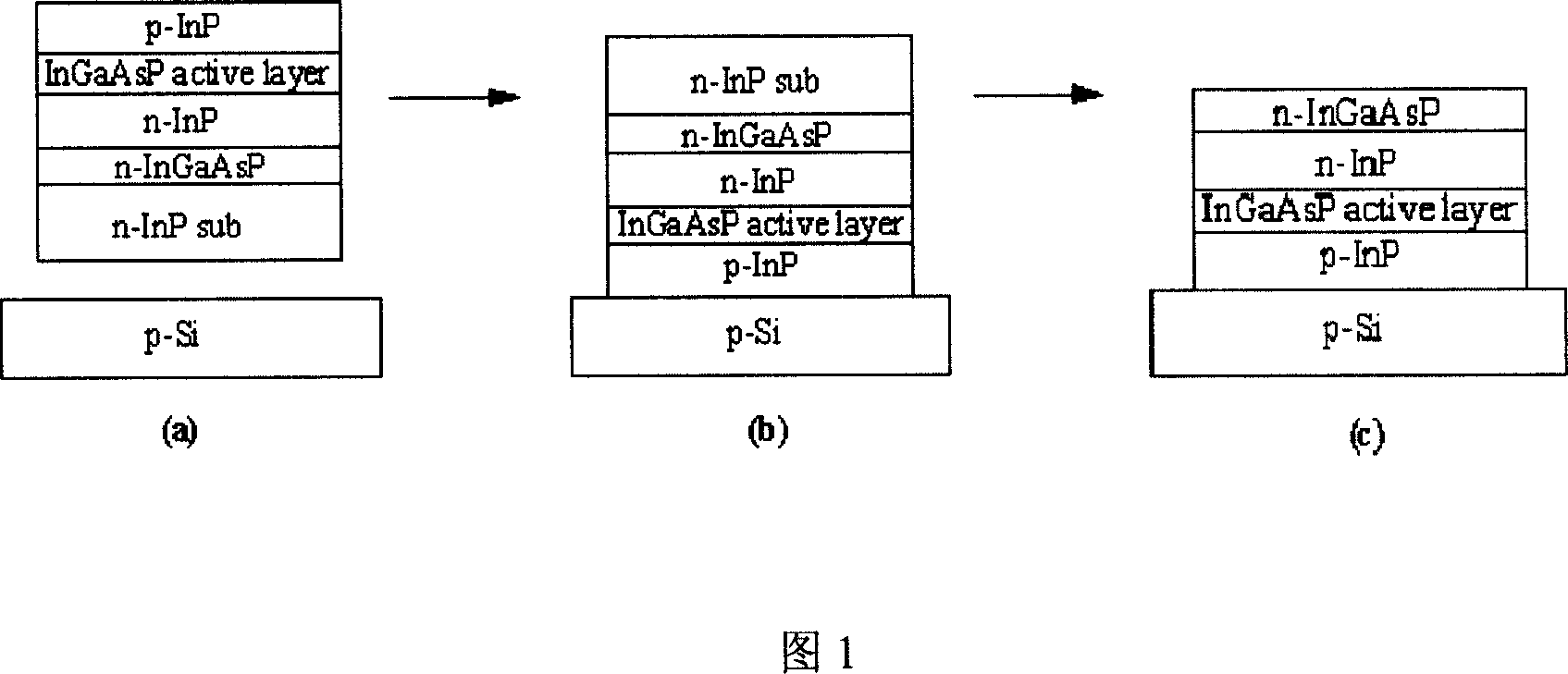

[0039] The InP-based wafer and the p-type Si wafer with the quantum well epitaxial structure in Fig. 1 are bonded together after the cleaning process, and then the bonding energy is improved through the above-mentioned thinning and heating process. The InP substrate is subsequently etched away by wet etching.

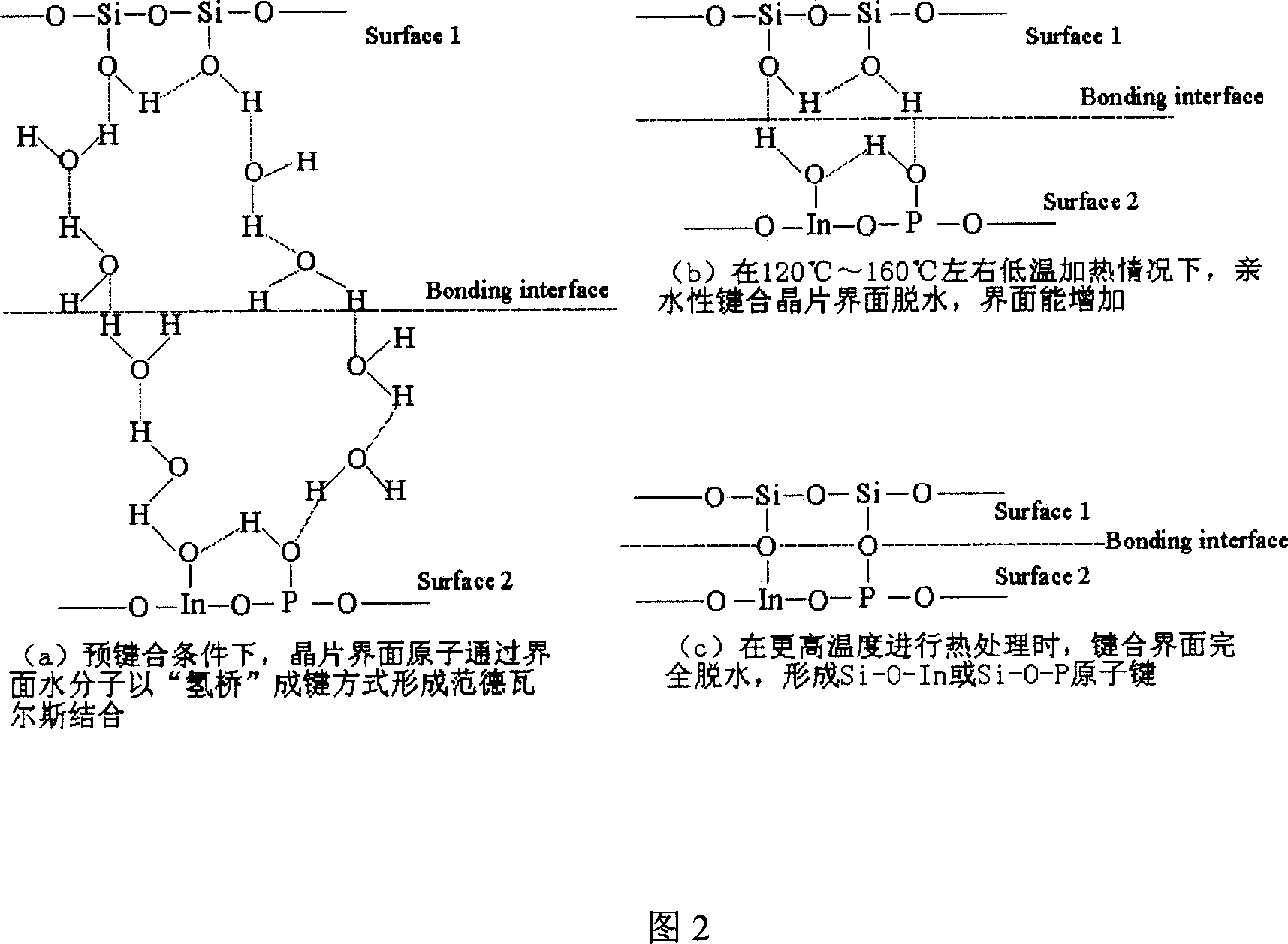

[0040] Figure 2(a) shows the "hydrogen bridge" van der Waals bonding formed by water molecules between the wafer interfaces in the case of low temperature (below 100°C) pre-bonding; (b) shows that when the temperature rises to about 120-160°C At this time, the interface water molecules are partially evaporated to form a short-range combination of water molecules. At this time, the interface surface energy is enough to thin the wafer; (c) shows that the bonded sheet is subjected to a higher temperature at a temperature above 200 ° C. During processing, the interfacial water molecules escape completely and the interface begins to form covalent bonds.

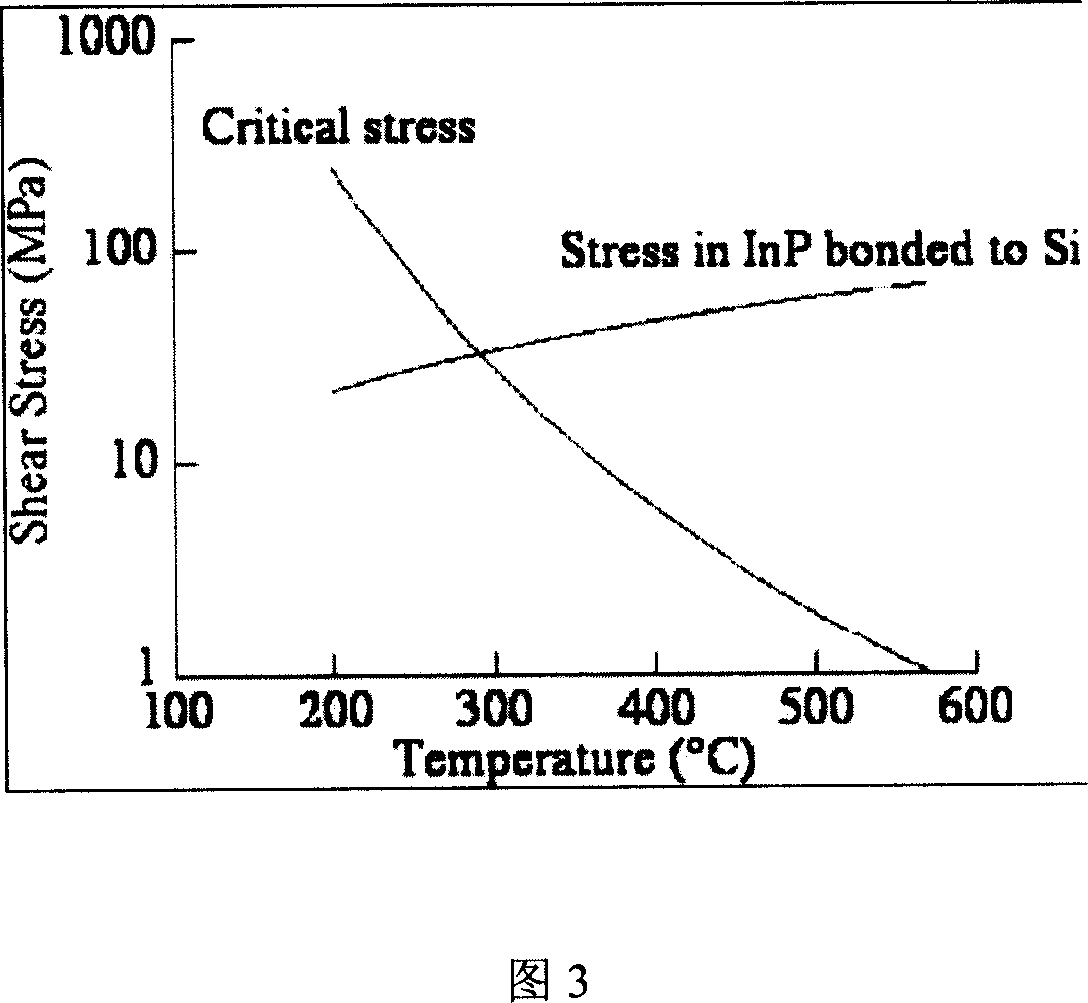

[0041] Figure 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com