Continuous production process of high purity trimellitic anhydride with trimellitic acid

A technology of trimellitic acid and trimellitic anhydride, applied in the direction of organic chemistry, etc., can solve the problems of inability to produce high-purity products, increased energy consumption of refined materials, serious material decomposition, etc., so as to avoid decomposition and coking, reduce decomposition and coking, and treat short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

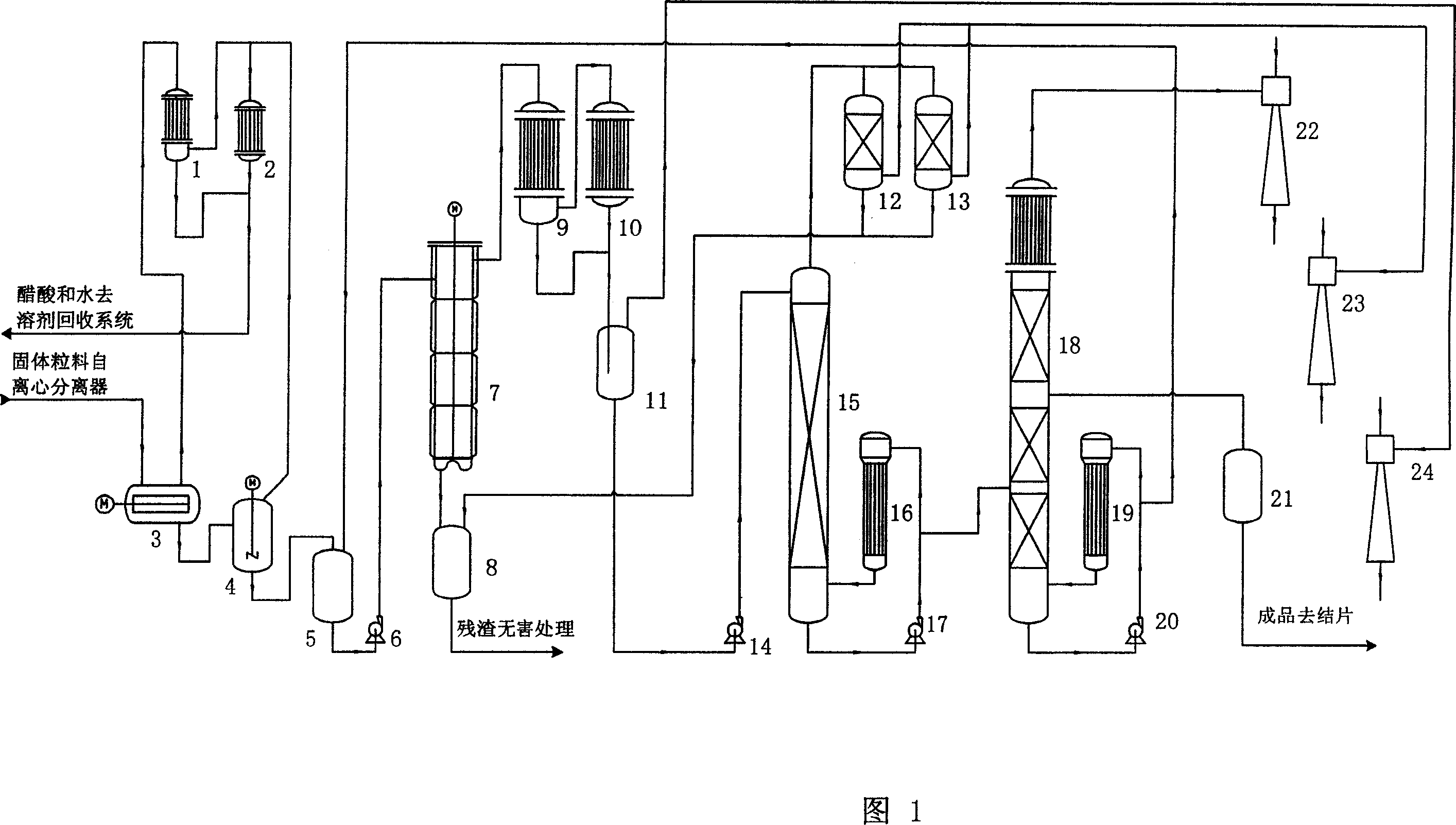

[0036] Embodiment 1 is the method for producing high-purity trimellitic anhydride through continuous anhydride formation of trimellitic acid of the present invention, specifically comprising the following process steps:

[0037] 1. Deacidification, dehydration, anhydride formation

[0038]Continuously drop 10000Kg of trimellitic acid granule wet material into 1# anhydride forming kettle 3, when the liquid level in 1# anhydride forming kettle reaches 60%, stop feeding, open the heating device to heat up, when the temperature in the kettle rises to ≥120 At ℃, start the stirring device of the anhydride forming kettle, continue to feed continuously into the anhydride forming kettle, control the temperature in the kettle at 120°C to 250°C, and the pressure at 0.05MPa to 0.15MPa, and the wet material of trimellitic acid particles is in the anhydride forming kettle It is melted into a liquid state, and the residual acetic acid and water brought in the granular wet material are remove...

Embodiment 2

[0046] 1. Deacidification, dehydration, anhydride formation

[0047] 15000Kg of trimellitic acid granule wet material is continuously dropped into 1# anhydride forming kettle 3, when the liquid level in the anhydride forming kettle reaches 60%, stop feeding, open the heating device and heat up, when the temperature in the still rises to ≥120°C, Start the stirring device of the anhydride forming kettle, continue to feed continuously into the anhydride forming kettle, control the temperature in the kettle at 160°C to 240°C, and the pressure at 0.05MPa to 0.15MPa, and the wet material of trimellitic acid particles is melted in the anhydride forming kettle Liquid state, and remove the residual acetic acid and water brought in the granular wet material. Trimellitic acid after dehydration enters 2# anhydride forming kettle 4, continues to remove a molecule of water in the molecule, steams and extracts acetic acid and water 2660Kg, and steam goes to the acetic acid concentration syst...

Embodiment 3

[0055] 1. Deacidification, dehydration, anhydride formation

[0056] Continuously put 20000Kg of trimellitic acid granule wet material into 1# anhydride forming kettle 3. When the liquid level in the kettle reaches 60%, stop feeding, turn on the heating device to raise the temperature, and when the temperature in the kettle rises to ≥120°C, start Anhydride forming tank stirring device, continue to feed continuously into the tank, control the temperature in the tank at 180 ° C ~ 230 ° C, the pressure is 0.05 MPa ~ 0.15 MPa, the wet material of trimellitic acid particles is melted into a liquid state in the 1# anhydride forming tank , and remove the residual acetic acid and water brought in the granular wet material. Trimellitic acid after dehydration enters 2# anhydride forming kettle 4, continues to remove a molecule of water in the molecule, steams and extracts acetic acid and water 3550Kg, and steam goes to the acetic acid concentration system after anhydride forming condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com