Heat pipe hot pump composite drying power source system

A power source system and composite technology, applied in heat recovery systems, drying, dryers, etc., can solve problems such as combination difficulties, and achieve the effects of no environmental pollution energy, wide application range, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

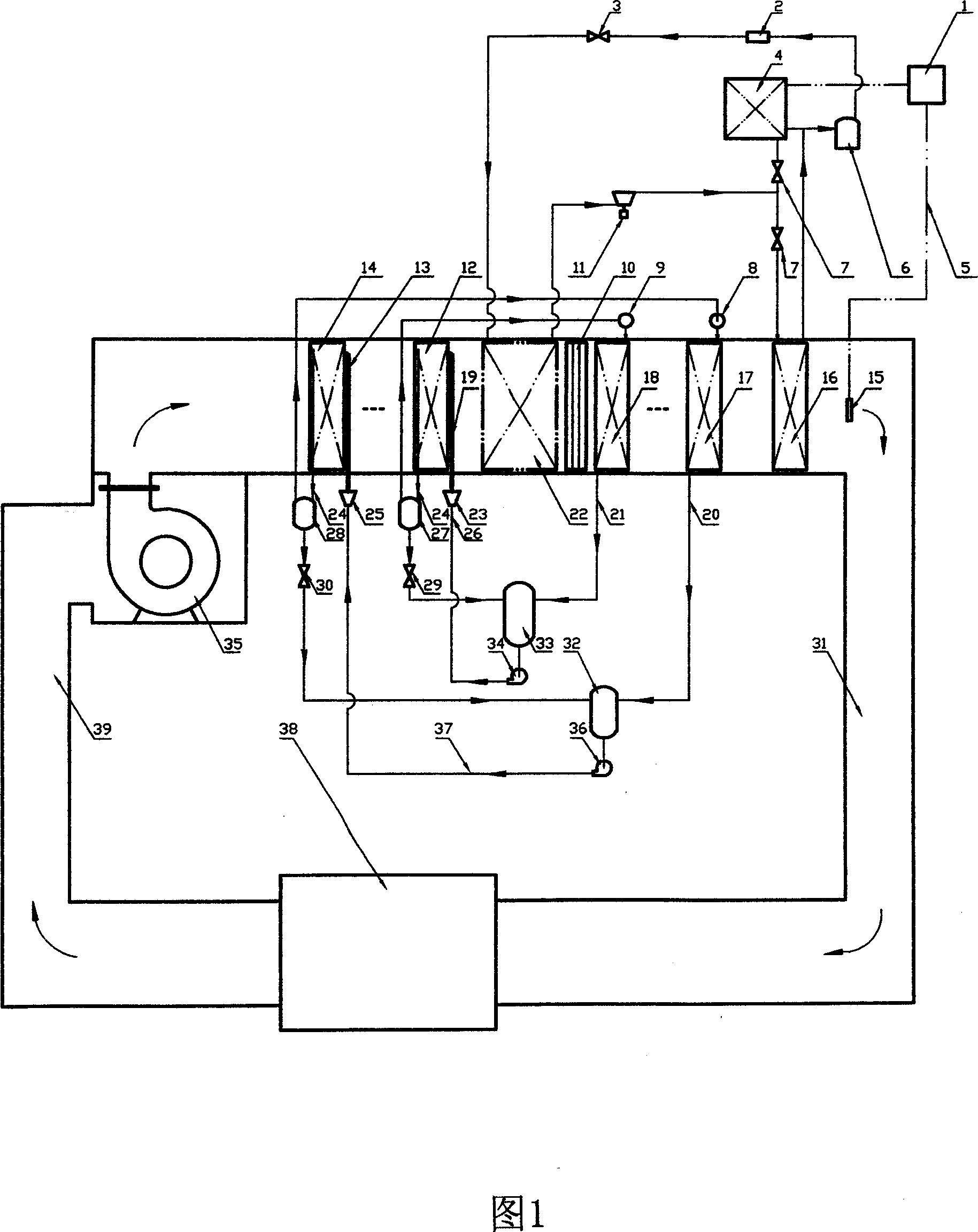

[0033] Embodiment 1: Figure 1 is a fully closed circulation type, with a total of n heat pipe cooling capacity recovery subsystems, the closest to the heat pump subsystem is the inner circulation heat pipe cooling capacity recovery subsystem, and the farthest from the heat pump subsystem is the outer circulation heat pipe cooling capacity recovery subsystem. The whole system is composed of a heat pump subsystem, n (1≤n≤20) heat pipe cooling capacity recovery subsystem, water baffle 10, air flow subsystem, air supply temperature control subsystem, drying room (or drying room) 38, etc. . The heat pump subsystem has one evaporator 22 in total, and its condenser is composed of an internal condenser 16 and an external condenser 4 connected in parallel, and the flow distribution ratio in the internal and external condensers is adjusted through two flow regulating valves 7; the power of the fan 35 Under the action, the air first flows through the evaporator 14 of the outer circulati...

Embodiment 2

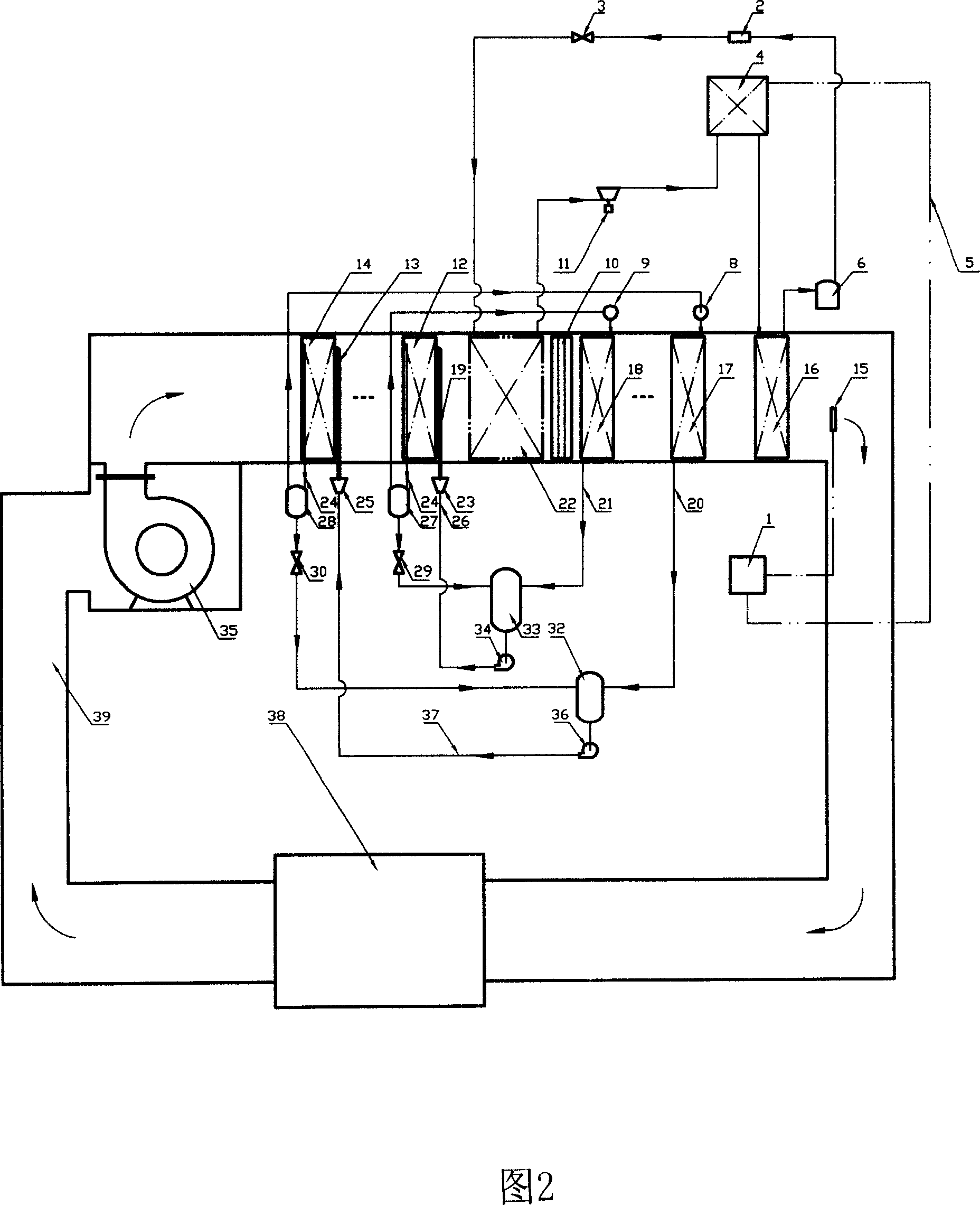

[0037] Embodiment 2: The structure of Fig. 2 is basically the same as that of Embodiment 1. The difference is the connection mode of the inner and outer condensers in the heat pump subsystem. The inner and outer condensers in Embodiment 1 are connected in parallel. Through two The flow regulating valve 7 is used to properly adjust the distribution of internal and external heat, while the internal and external condensers in Embodiment 2 are connected in series, and the flow rates in the two condensers are the same, and the energy distribution is realized entirely by adjusting the heat taken away by the external condenser. balance. The start-up and operation process of the system device is the same as that of Embodiment 1.

Embodiment 3

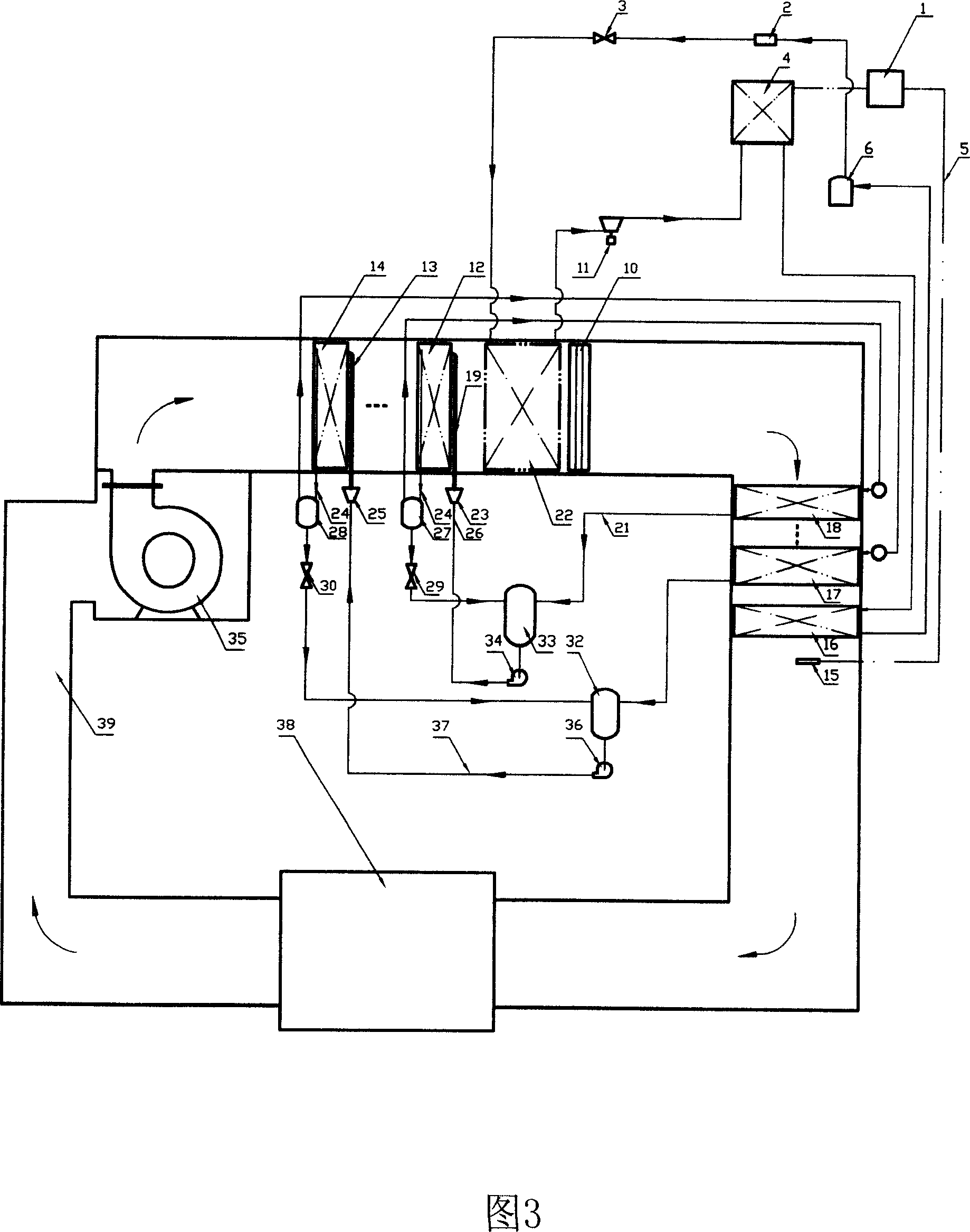

[0038] Embodiment 3: Fig. 3 is a fully closed circulation type, which is basically the same structure as Embodiment 2, but the arrangement is different. In Embodiment 2, the condenser of the heat pipe cold recovery subsystem and the condenser of the heat pump subsystem are arranged vertically, while in this embodiment, the condenser of the heat pipe cold recovery subsystem and the condenser of the heat pump subsystem are all arranged horizontally. The way it is arranged. The start-up and operation process of the system device is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com