Nano zirconium oxide based wearable sealing composite coating material and preparation method thereof

A zirconia-based, composite coating technology, applied in coatings, polyester coatings, etc., can solve problems such as excessive coating hardness, coating failure, and adhesion, and achieve smooth coating, precise control of thickness, and bonding high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

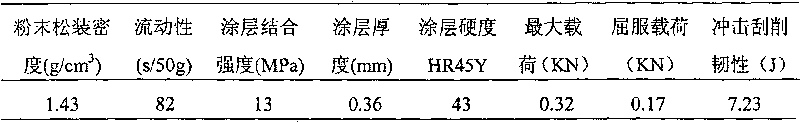

Examples

Embodiment 1

[0042] Take CeO with a particle size of 20-60nm 2 +Y 2 o 3 Stabilized ZrO 2 3.28kg of powder, 0.675kg of h-BN with a particle size of 60-500nm, 0.54kg of polyphenylene with a particle size of 6-10μm, and then add 0.225kg of adhesive, after thorough mixing, add 3.5kg of distilled water and stir to disperse evenly The suspended slurry is ready for use. The CeO 2 +Y 2 o 3 Stabilized ZrO 2 Y in powder 2 o 3 The content of CeO is 5-7mol%. 2 The content is 10~13mol%. The adhesive is any one of dextrin, polyvinyl alcohol, carboxymethyl cellulose, polystyrene or any two or any mixture of two or more, when any two or any two or more are mixed , for any ratio. Use a pH tester to control and adjust the pH value of the slurry by adding dilute hydrochloric acid dropwise, and the pH value is 6-6.5.

[0043] Dry and pure compressed air is used as the carrying gas, the gas pressure is controlled at 0.8MPa, and the slurry is sprayed into the drying tower by a two-flow nozzle. The...

Embodiment 2

[0049] Take Sc with a particle size of 20-60nm 2 o 3 +Y 2 o 3 Stabilized ZrO 2 7.5kg of powder, 1.5kg of h-BN with a particle size of 60-500nm, 1.5kg of polyphenylene with a particle size of 6-10μm, and then add 0.5kg of adhesive, after thorough mixing, add 7.8kg of distilled water to stir and disperse evenly The suspended slurry is ready for use. The Sc 2 o 3 +Y 2 o 3 Stabilized ZrO 2 Y in powder 2 o 3 The content is 5%~7mol%, Sc 2 o 3 The content is 10%~13mol%. The adhesive is any one of dextrin, polyvinyl alcohol, carboxymethyl cellulose, polystyrene or any two or any mixture of two or more, when any two or any two or more are mixed , for any ratio. Use a pH tester to control and adjust the pH value of the slurry by adding dilute hydrochloric acid dropwise, and the pH value is 6-6.5.

[0050] Use dry and pure compressed air as the carrying gas, the gas pressure is controlled at 0.8MPa, and the slurry is sprayed into the drying tower with a two-flow nozzle. T...

Embodiment 3

[0056] Take Sc with a particle size of 20-60nm 2 o 3 +Y 2 o 3 Stabilized ZrO 2 10.5kg of powder, 3.0kg of diatomite with a particle size of 60-500nm, 1.5kg of polyester with a particle size of 6-10μm, and then add 0.75kg of adhesive, after thorough mixing, add 12kg of distilled water and stir to disperse and suspend evenly The slurry is ready for use. The Sc 2 o 3 +Y 2 o 3 Stabilized ZrO 2 Y in powder 2 o 3 The content of Sc is 5-7mol%. 2 o 3 The content is 10~13mol%. The adhesive is any one of dextrin, polyvinyl alcohol, carboxymethyl cellulose, polystyrene or any two or any mixture of two or more, when any two or any two or more are mixed , for any ratio. Use a pH tester to control and adjust the pH value of the slurry by adding dilute hydrochloric acid dropwise, and the pH value is 6-6.5.

[0057] Use dry and pure compressed air as the carrying gas, the gas pressure is controlled at 0.8MPa, and the slurry is sprayed into the drying tower by a two-flow nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com