A kind of infinite water dilutable oil-in-water microemulsion cleaning agent and preparation method thereof

An oil-in-water type and microemulsion technology, applied in the field of daily chemical products, can solve problems such as health hazards, fire safety hazards, and inability to quickly remove heavy oil, etc., to achieve good stability, large oil capacity, fast and efficient The effect of dissolving oil stains and solubilizing oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

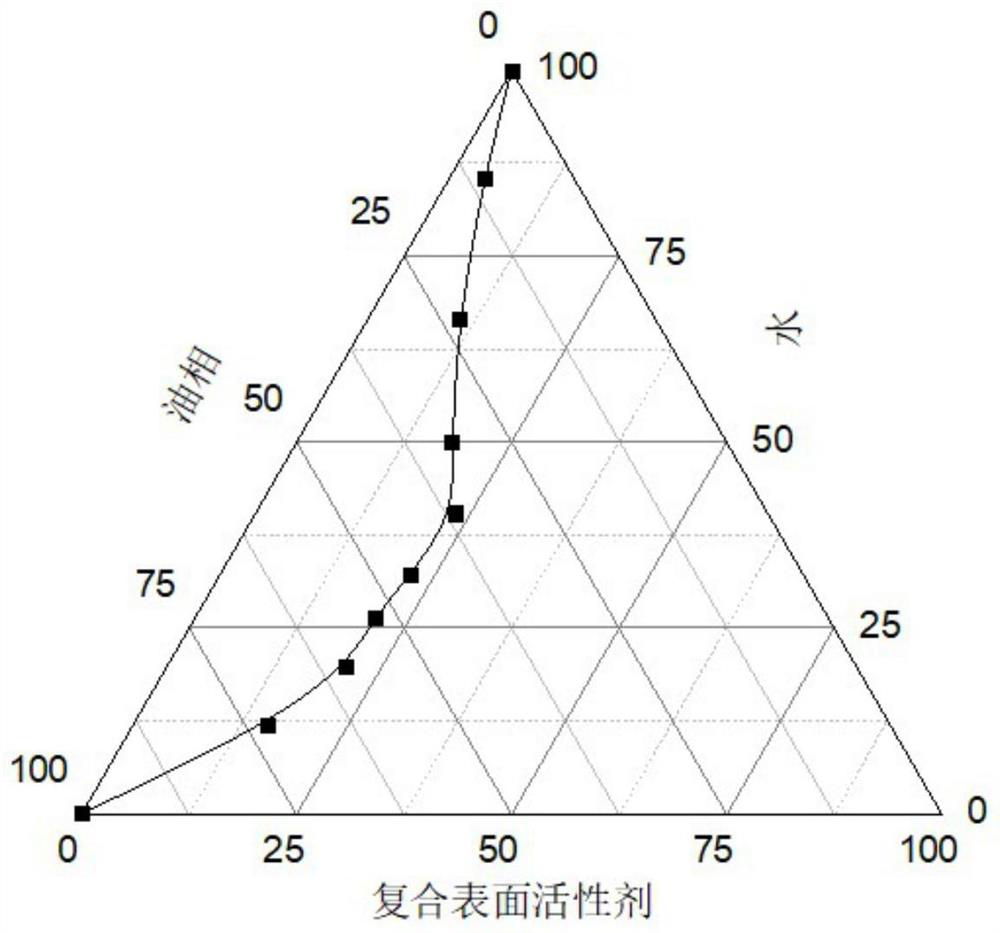

[0031] This embodiment constructs the pseudo-ternary phase diagram of microemulsion by titration method. According to the mass ratio of the oil phase (peanut oil, Shandong Luhua Group Co., Ltd.) and the composite surfactant are 10:0, 9:1, 8:2, 7:3, 6:4, 5:5, 4:6 , 3:7, 2:8, 1:9, and 0:10 samples were mixed evenly, and the mixed samples with different ratios were taken to equal mass, and placed in 10mL stoppered test tubes, and vortexed at 30 ° C. Mix well, equilibrate for at least 30min, add deionized water at the same temperature dropwise to the test tube, mix well, repeat the operation until the solution changes from turbid to clear, or from clear to turbid, determine the multi-phase area and single-phase area, draw the pseudo Ternary phase diagram, see figure 1 . Depend on figure 1 It can be seen that the system has multiple infinite water dilution channels and has a large microemulsion area.

Embodiment 2

[0033] This embodiment is the preparation of infinite water dilutable green oil-in-water microemulsion cleaner. The average molecular weight of raw material oligomeric chitosan is: 960. The specific preparation process is: soybean oil (Shandong Luhua Group Co., Ltd.) is the oil phase; 10g of isomerized decanol polyoxyethylene ether (E-1005), 20g of carboxymethyl chitosan tetradecyl quaternary ammonium salt ( 14-QACMC), 10g alkyl glucoside (APG1214) were homogenized and mixed with a homogeneous emulsifier to obtain a composite surfactant; 1g of the oil phase and 1g of the composite surfactant were homogenized and mixed to obtain agent A, and Add 20g of deionized water to Agent A, homogenize and mix, and dilute the green oil-in-water microemulsion cleaner with DEK infinite water.

Embodiment 3

[0035] This embodiment is the preparation of infinite water dilutable green oil-in-water microemulsion cleaner. The average molecular weight of raw material oligomeric chitosan is: 1500. The specific process is: corn oil (Shandong Luhua Group Co., Ltd.) is the oil phase; 10g isomerized decanol polyoxyethylene ether (E-1006), 20g carboxymethyl chitosan tetradecyl quaternary ammonium salt (14 -QACMC), 10g alkyl glucoside (APG1214) are homogenized and mixed with a homogeneous emulsifier to obtain a composite surfactant; get 1g of oil phase and 2g of a composite surfactant to homogenize and mix to obtain agent A, and send to A Add 36g of deionized water to the agent, homogenize and mix, and dilute the green oil-in-water microemulsion cleaner with infinite water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com