Fabric reinforced cement

A technology for reinforced cement and fabric reinforcement, applied in the directions of nonwovens, textiles and papermaking, thin material processing, etc., can solve the problems of easy corrosion or degradation, insufficient tensile modulus, panels, composite materials and sheet tensile reinforcements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All patents and applications mentioned herein are hereby incorporated by reference in their entirety.

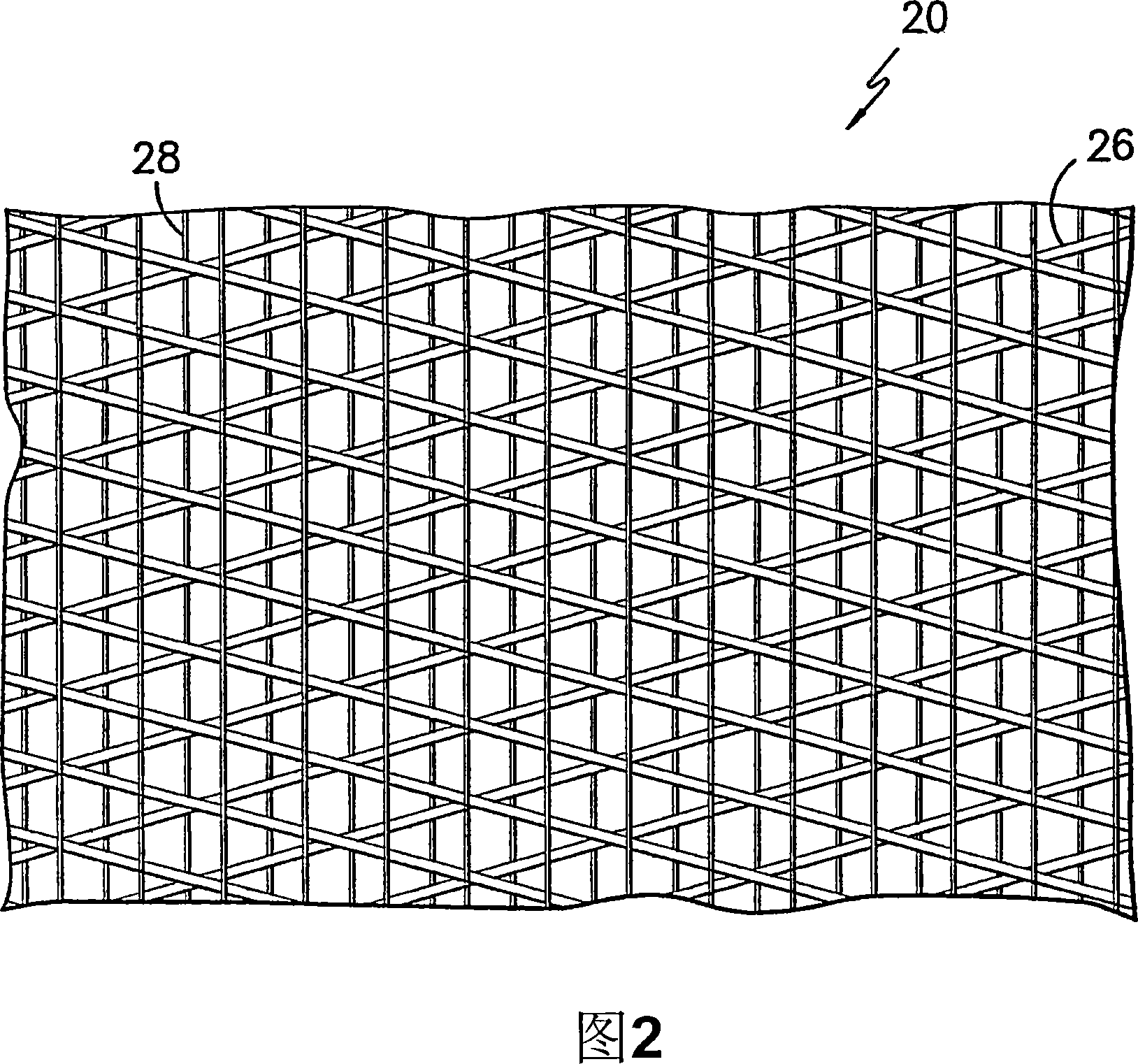

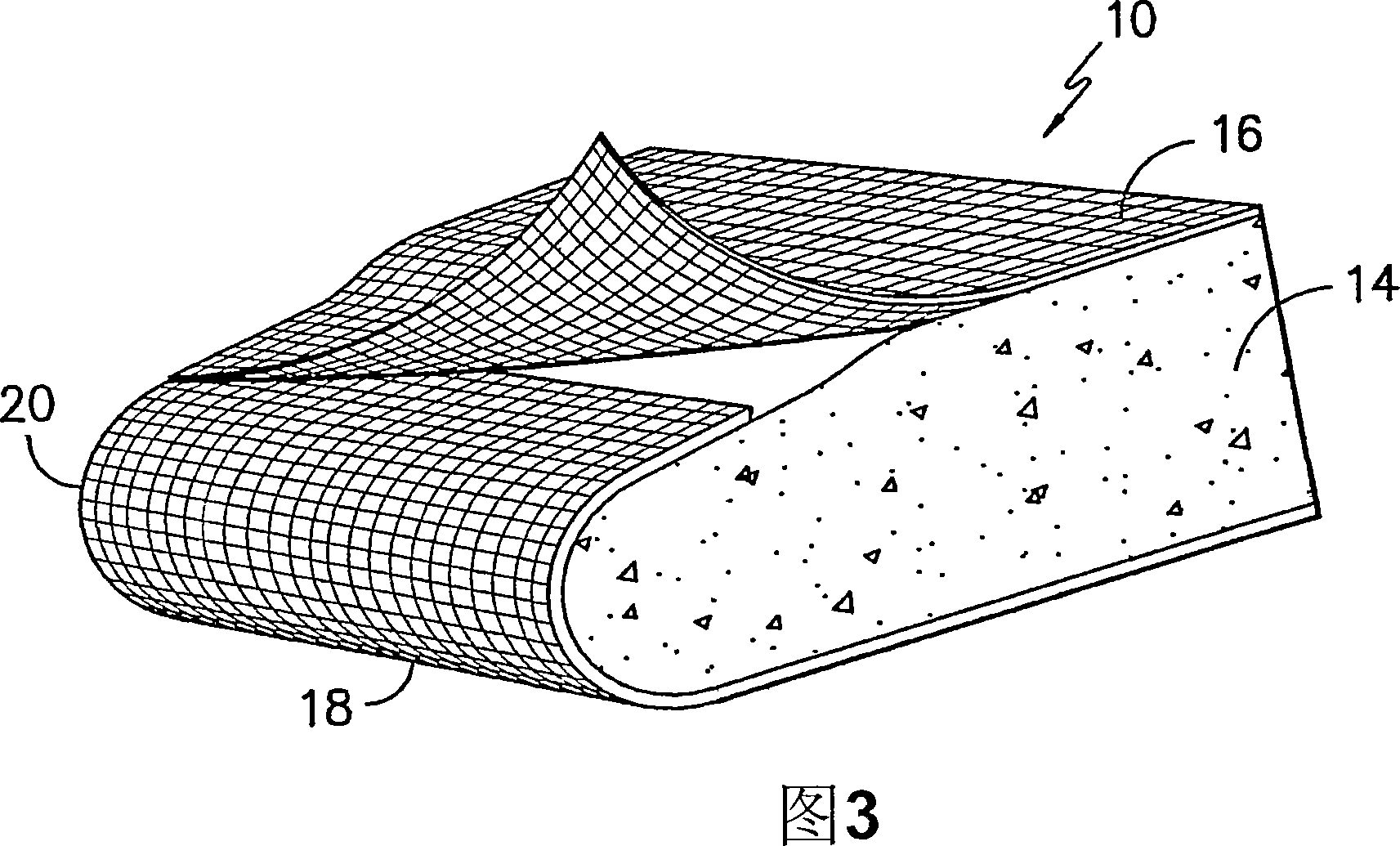

[0025] The present invention relates to fabric reinforcements comprising high modulus polyolefin monofilament yarns for cementitious products, composites, panels and boards. This high modulus monofilament yarn is polyolefin based and consists primarily of polypropylene. High modulus yarns, optionally including nucleating agents, are made according to the teachings herein.

[0026] The term "polypropylene" is intended to include any polymeric composition comprising propylene monomers, either alone or in combination with other randomly selected and oriented polyolefins, dienes or other monomers such as ethylene, butene and the like ) in mixtures or copolymers. The term also includes different configurations and arrangements of the monomeric components (eg, syndiotactic, isotactic, and the like). Thus, as applied to fibers, the term is intended to include actual stran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com