Powder and liquid bag and preparation method thereof

A production method and container technology, which is applied in the direction of chemical instruments and methods, containers, medical containers, etc., can solve the problems of complex processing technology and easy liquid leakage, achieve high transparency, low production cost, and reduce the burden of drug prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

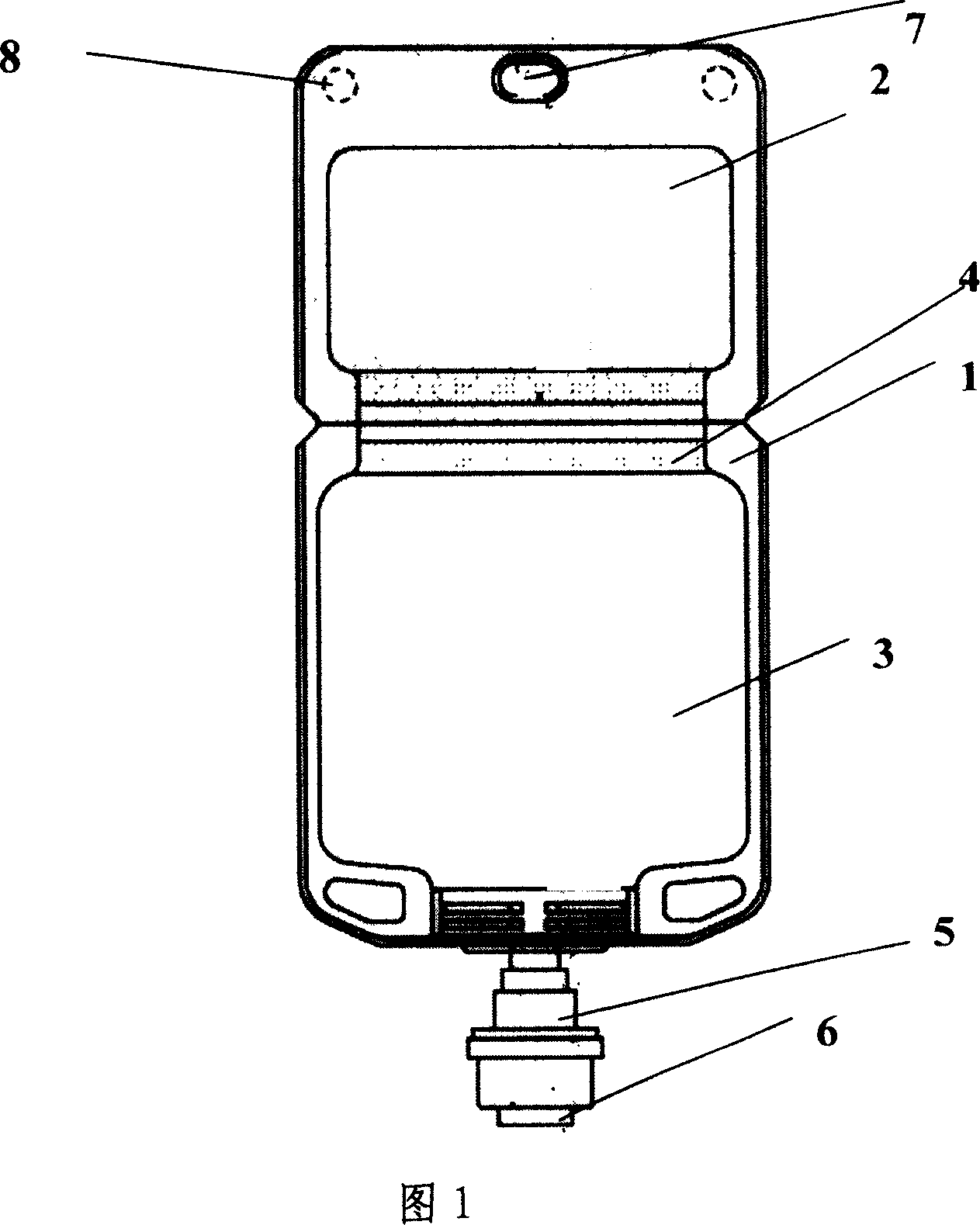

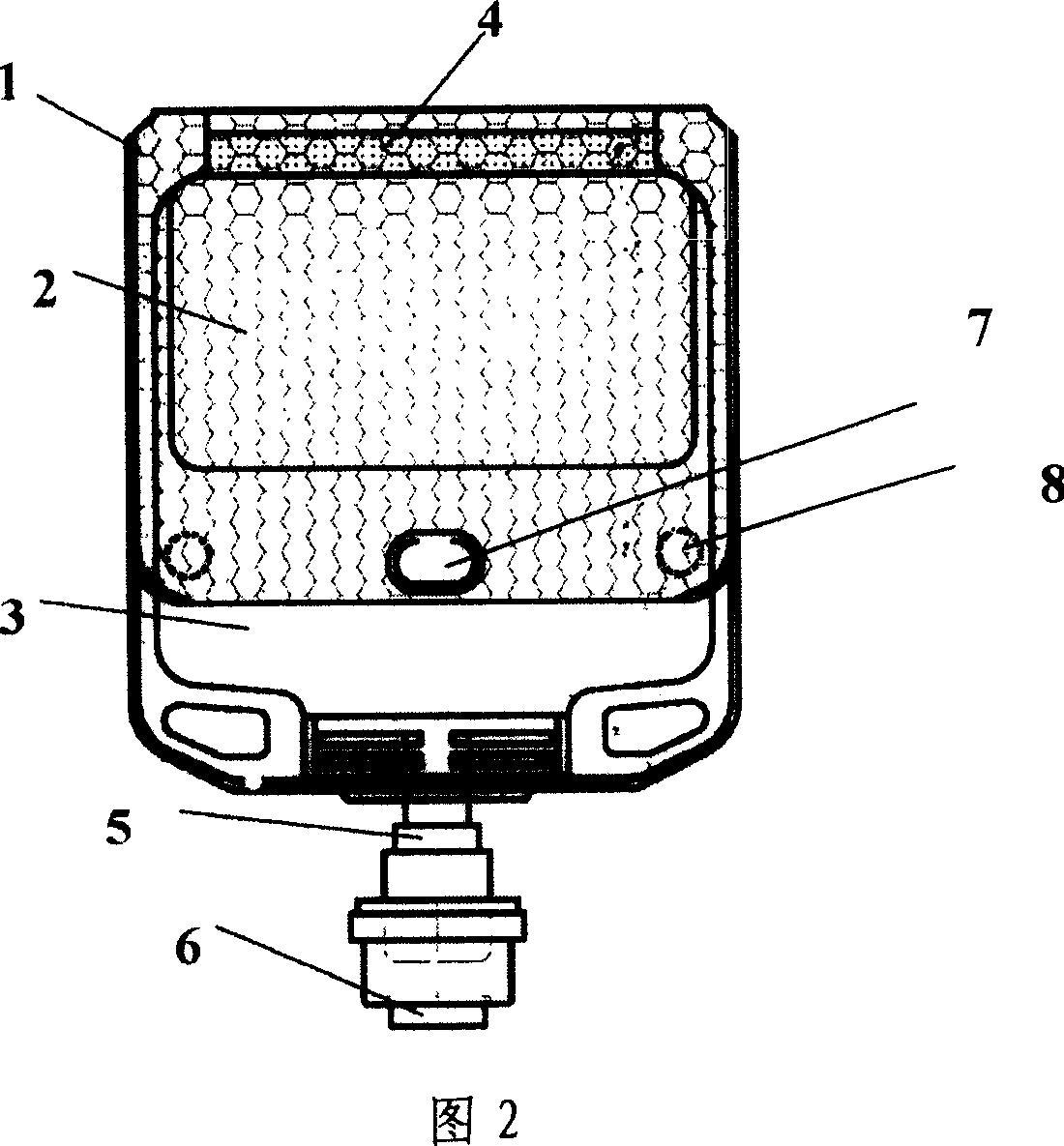

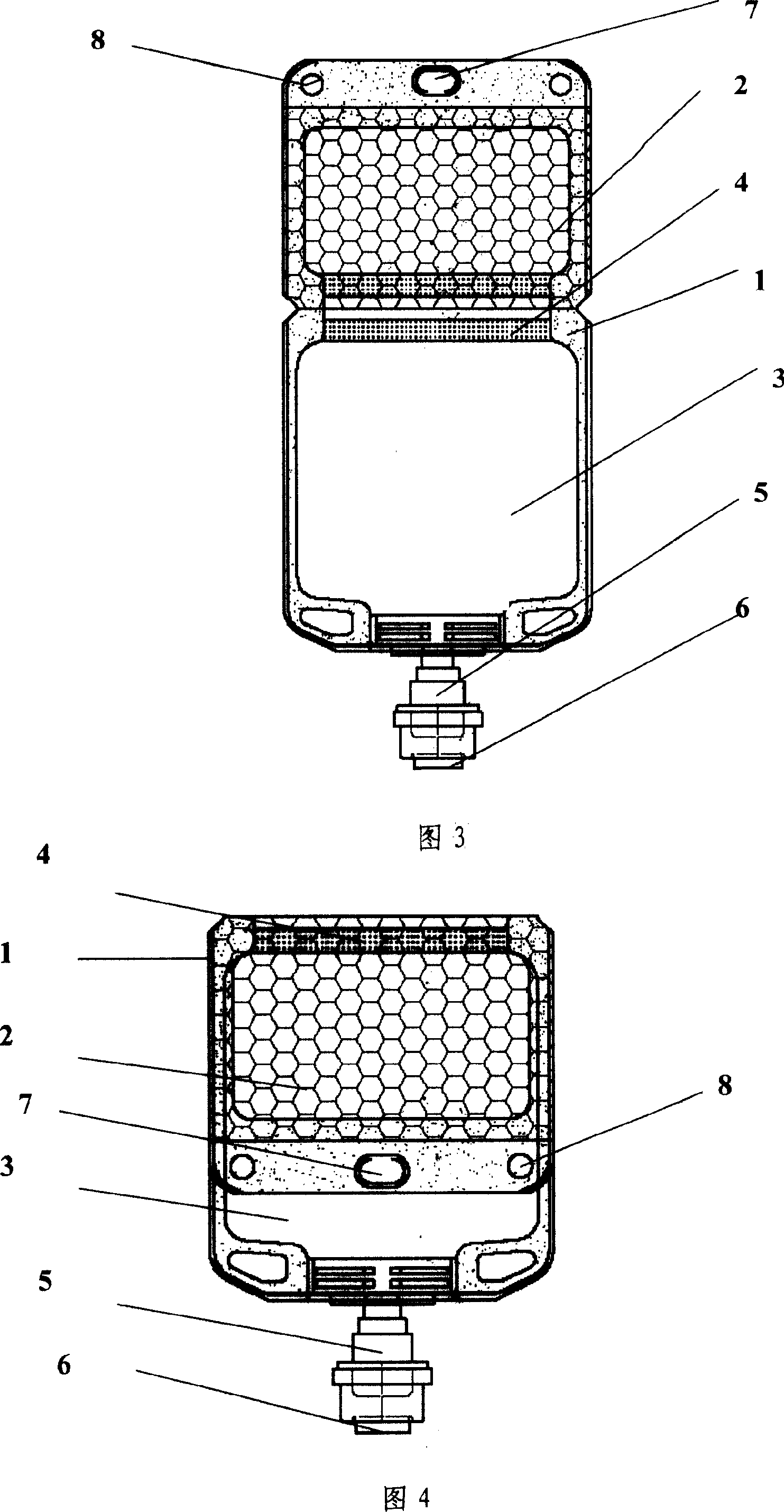

[0048] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the powder-liquid bag container of the present invention is composed of a sealed bag body 1, and the sealed bag body 1 is formed by connecting two pieces of bag films at the periphery. At least one powder chamber 2 and one liquid chamber 3 are arranged in the bag body 1, and any one of the powder chambers 2 is isolated from any adjacent powder chamber 2 or liquid chamber 3 by a partition 4, The partition 4 is composed of the two pieces of bag film connected by a peelable virtual welding structure, at least one partition 4 is arranged in the bag body 1, and any one of the bag films is composed of at least one layer The two outer surfaces of the bag film of the powder chamber are provided with a layer of barrier film.

[0049] Further, any piece of the bag film is composed of three layers of film.

[0050] Further, the bag body 1 is provided with two powder chambers 2 and one liquid chamber 3, the two powder chambers 2 are i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com