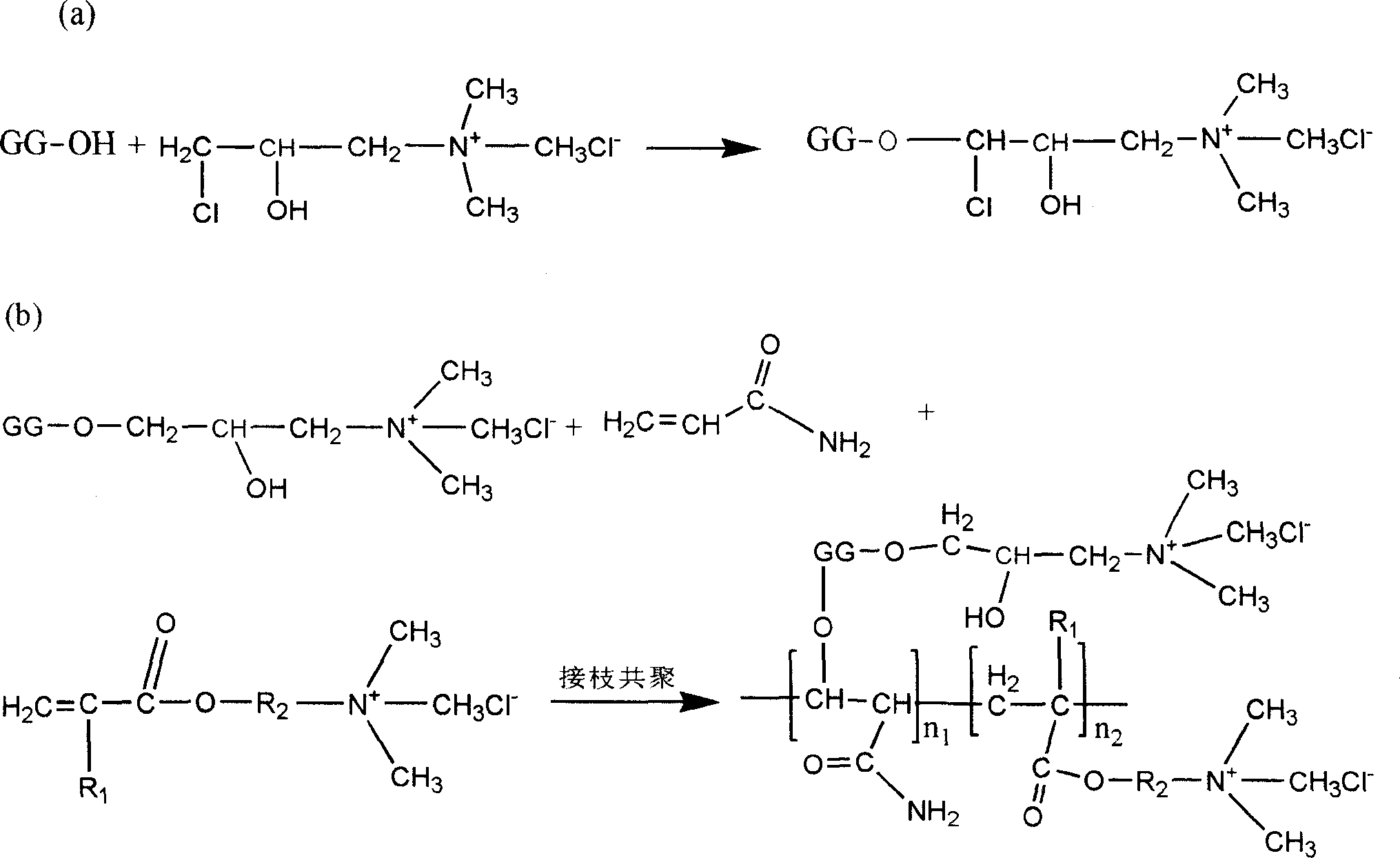

Preparation method and use of cation guar gum graft copolymer retention and drainage agent

A technology of cationic guar gum and graft copolymer, which is applied in the system field, can solve problems such as uselessness, and achieve the effects of reducing white water turbidity, improving purification, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Disperse 100 grams of unpurified guar collagen powder into a mixture of 40 grams of alcohol and 10 grams of water, add it to an ordinary three-neck bottle, ventilate nitrogen, stir evenly at room temperature, add 10 grams of 3-chloro-2-hydroxypropyl Trimethyl ammonium chloride and the solution of 10 grams of water, dropwise add 10 grams of sodium hydroxide aqueous solution (sodium hydroxide concentration 50%), stir and mix evenly, then material is placed in 65 ℃ of constant temperature ovens and reacts after 3.5 hours, Cool to room temperature, neutralize the pH to 6-7 with a small amount of acetic acid, filter with suction, and dry the filter cake in a vacuum oven at 65°C for 12 hours to obtain a cationic guar gum product, with a cationic substitution degree of 0.015.

[0042] Get above-mentioned product 10 grams, be dissolved in 833 grams of distilled water, obtain colorless transparent solution, pass into nitrogen and stir, add the nitric acid solution of ceric ammoni...

Embodiment 2

[0044] Disperse 100 grams of unpurified guar collagen powder into a mixture of 70 grams of alcohol and 10 grams of water, add it to an ordinary three-necked bottle, ventilate nitrogen, stir evenly at room temperature, add 25 grams of 3-chloro-2-hydroxypropyl Trimethyl ammonium chloride and the solution of 10 grams of water, add dropwise 50 grams of sodium hydroxide aqueous solution (sodium hydroxide concentration 10%), stir and mix evenly, then material is placed in 75 ℃ of constant temperature ovens and reacts after 6 hours, Cool to room temperature, neutralize the pH to 6-7 with a small amount of acetic acid, filter with suction, and dry the filter cake in a vacuum oven at 50°C for 24 hours to obtain a cationic guar gum product, with a cationic substitution degree of 0.036.

[0045] Take 10 grams of the above-mentioned product, dissolve it in 190 grams of distilled water to obtain a colorless transparent solution, feed into nitrogen and stir, add the nitric acid solution of c...

Embodiment 3

[0047] 100 grams of unpurified guar collagen powder, dispersed into a mixture of 20 grams of alcohol and 10 grams of water, added to a common three-necked bottle, ventilated with nitrogen, stirred evenly at room temperature, added 5 grams of 3-chloro-2-hydroxypropyl Trimethyl ammonium chloride and the solution of 10 grams of water, dropwise add 10 grams of aqueous sodium hydroxide solution (sodium hydroxide concentration 50%) and mix evenly at a high speed, then place the material in a constant temperature oven at 40°C to react for 6 hours, Cool to room temperature, neutralize the pH to 6-7 with a small amount of acetic acid, filter with suction, and dry the filter cake in a vacuum oven at 75°C for 10 hours to obtain a cationic guar gum product, with a cationic substitution degree of 0.008.

[0048] Take 10 grams of the above-mentioned product, dissolve it in 323 grams of distilled water to obtain a colorless transparent solution, feed into nitrogen and stir, add the nitric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com