Outer heat preservation system of composite polyphenylene plate of hard bubble polyurethane for pouring in site, and construction technique

A rigid polyurethane foam and in-situ pouring technology, applied in thermal insulation, building components, climate change adaptation and other directions, can solve the problems of difficult control of the surface flatness and thickness of the thermal insulation layer, achieve standardization and simplification of engineering quality control, save construction costs, Excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

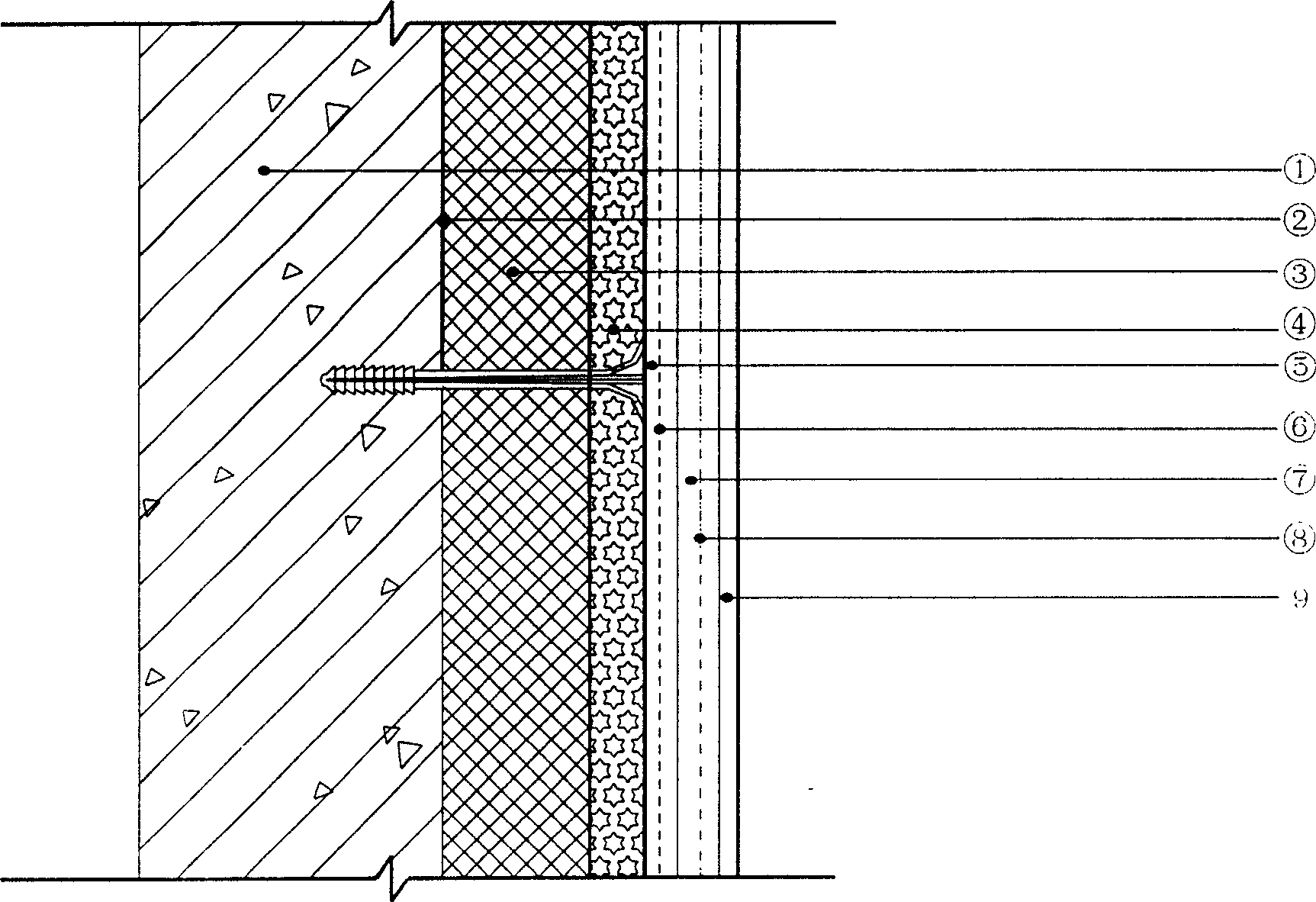

[0015] The structure disclosed in the above drawings is the structure of an embodiment of the present invention. In the figure, 1 is the base layer of the building structure wall (leveling may not be required); 2 is the interface layer; 3 is the cast-in-place hard polyurethane bonding insulation layer; 4 is the polystyrene board insulation layer; 5 is the plastering mortar layer; 6 is the Alkali-resistant grid cloth layer; 7 is a polymer emulsion elastic waterproof coating layer; 8 is a polyester non-woven carcass reinforcement layer; 9 is a paint finish layer.

[0016] Referring to the accompanying drawings, the cast-in-place rigid polyurethane composite polystyrene board exterior wall exterior thermal insulation coating system of the present invention includes a base layer 1, an interface layer 2, and a cast rigid polyurethane adhesive thermal insulation layer 3, which are sequentially formed outside the adhesive thermal insulation layer 3. Polystyrene board insulation layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com