Bio-activity tricalcium silicate/semi water calcium sulphate composite self-solidification material, preparation and application

A technology of calcium sulfate hemihydrate and tricalcium silicate, applied in the field of medical biological materials, can solve the problems of poor injectability of bone cement paste, no biological activity, inflammatory exudate, etc., and achieve excellent cytocompatibility , excellent biological activity, easy to repeat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Blending liquid preparation

[0051] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 g of deionized water to obtain a 1.0% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0052] 2) Preparation of tricalcium silicate / β-calcium sulfate hemihydrate composite bone defect filling material:

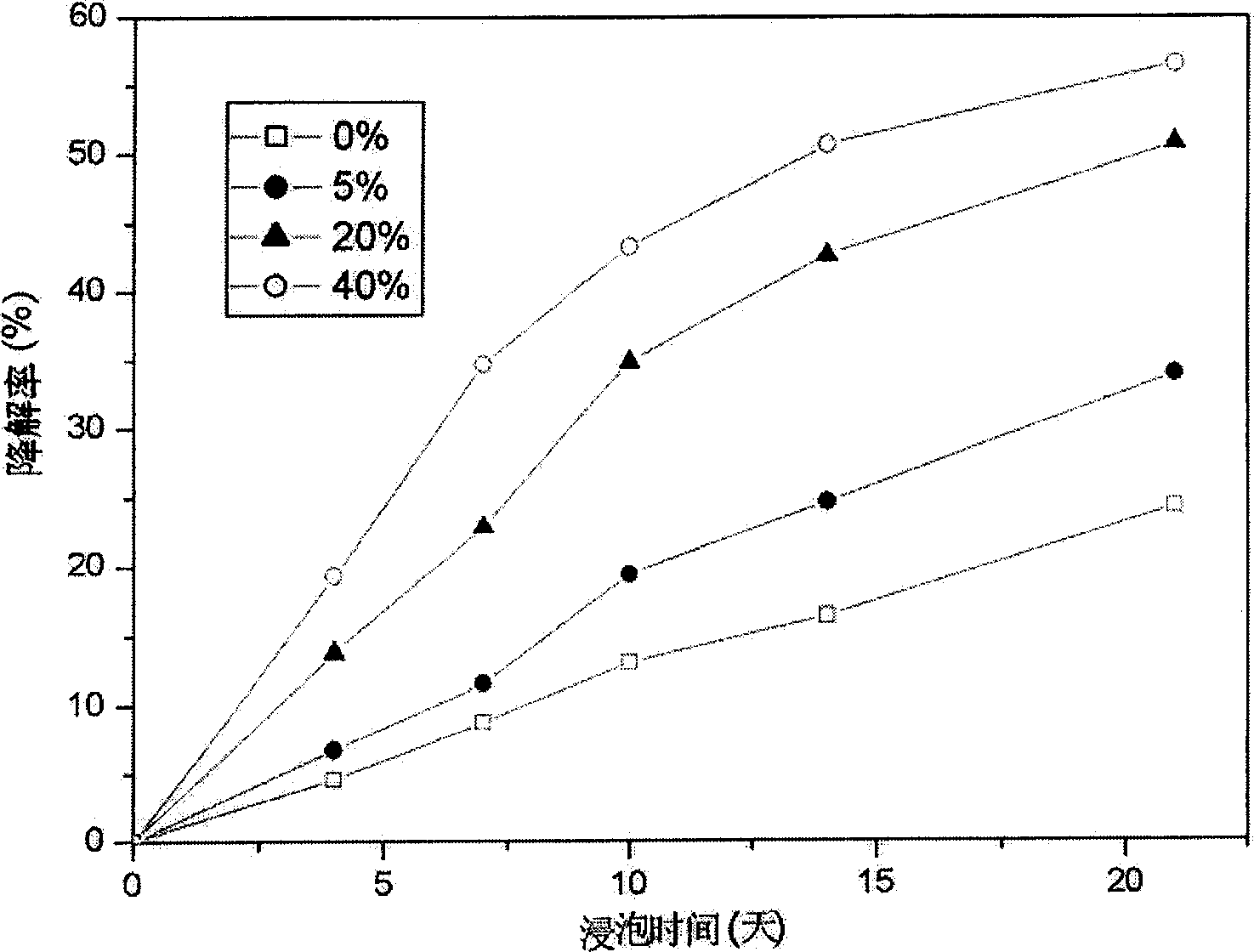

[0053] Tricalcium silicate and β-calcium sulfate hemihydrate powder are mixed at a mass ratio of 60:40 (the content of β-calcium sulfate hemihydrate is 40%) to obtain tricalcium silicate / β-calcium sulfate hemihydrate composite powder. The composite powder and the blending liquid are blended for 0.5-1 minute at a liquid-solid mass ratio of 0.8:1 to obtain the tricalcium silicate / β-calcium sulfate hemihydrate composite bone defect filling material. This material is not injectable, the initial setting and final setting time are 9 minutes and 12 minutes respectively; after curing for 28 days, the compressive strength is 37...

Embodiment 2

[0055] 1) Blending liquid preparation

[0056] Weigh 1.0 g of analytically pure gelatin and dissolve it in 99.0 g of deionized water to obtain a 1.0% gelatin solution, sterilize, seal in a sterile bottle, and set aside.

[0057] 2) Preparation of tricalcium silicate / β-calcium sulfate hemihydrate composite self-curing material:

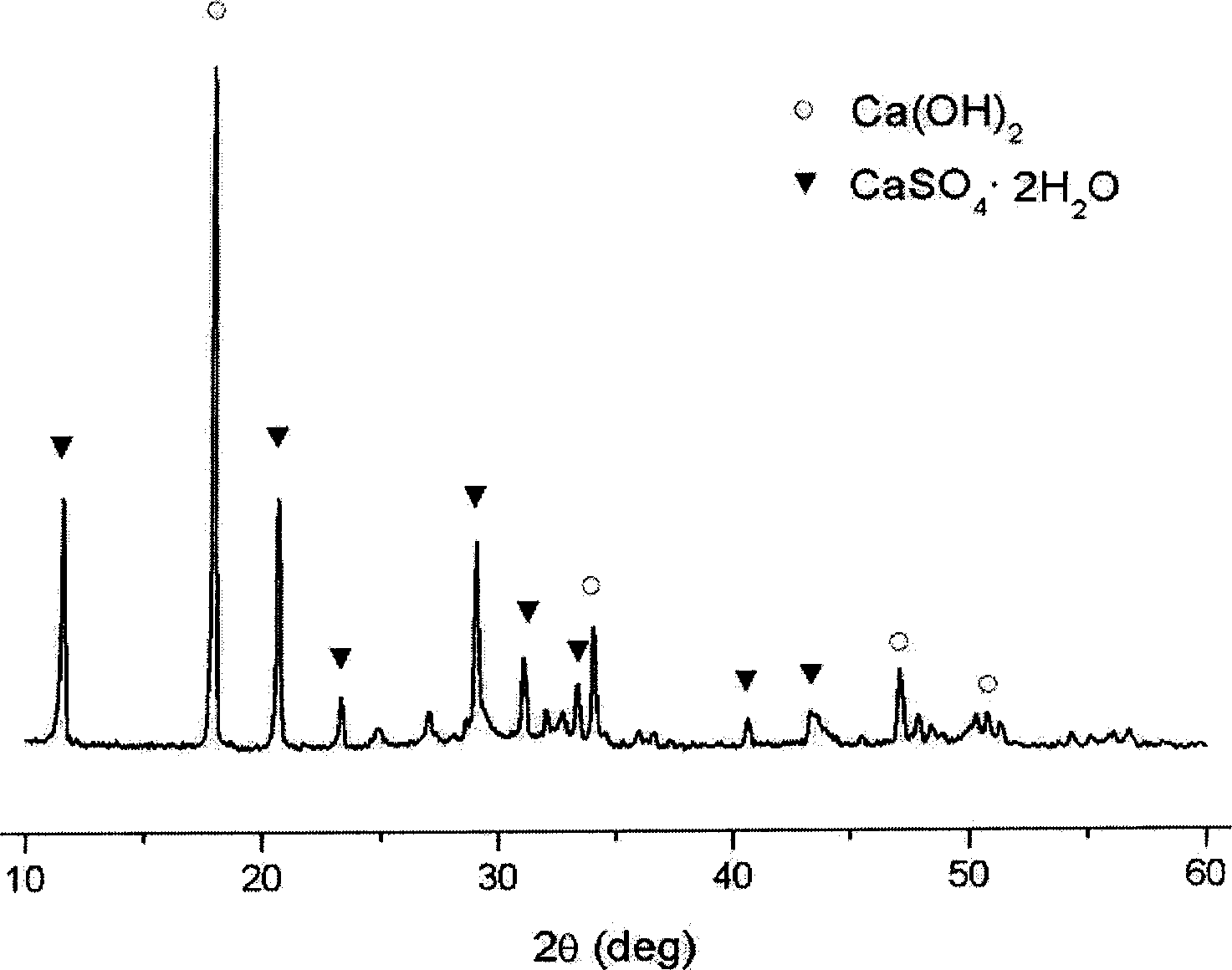

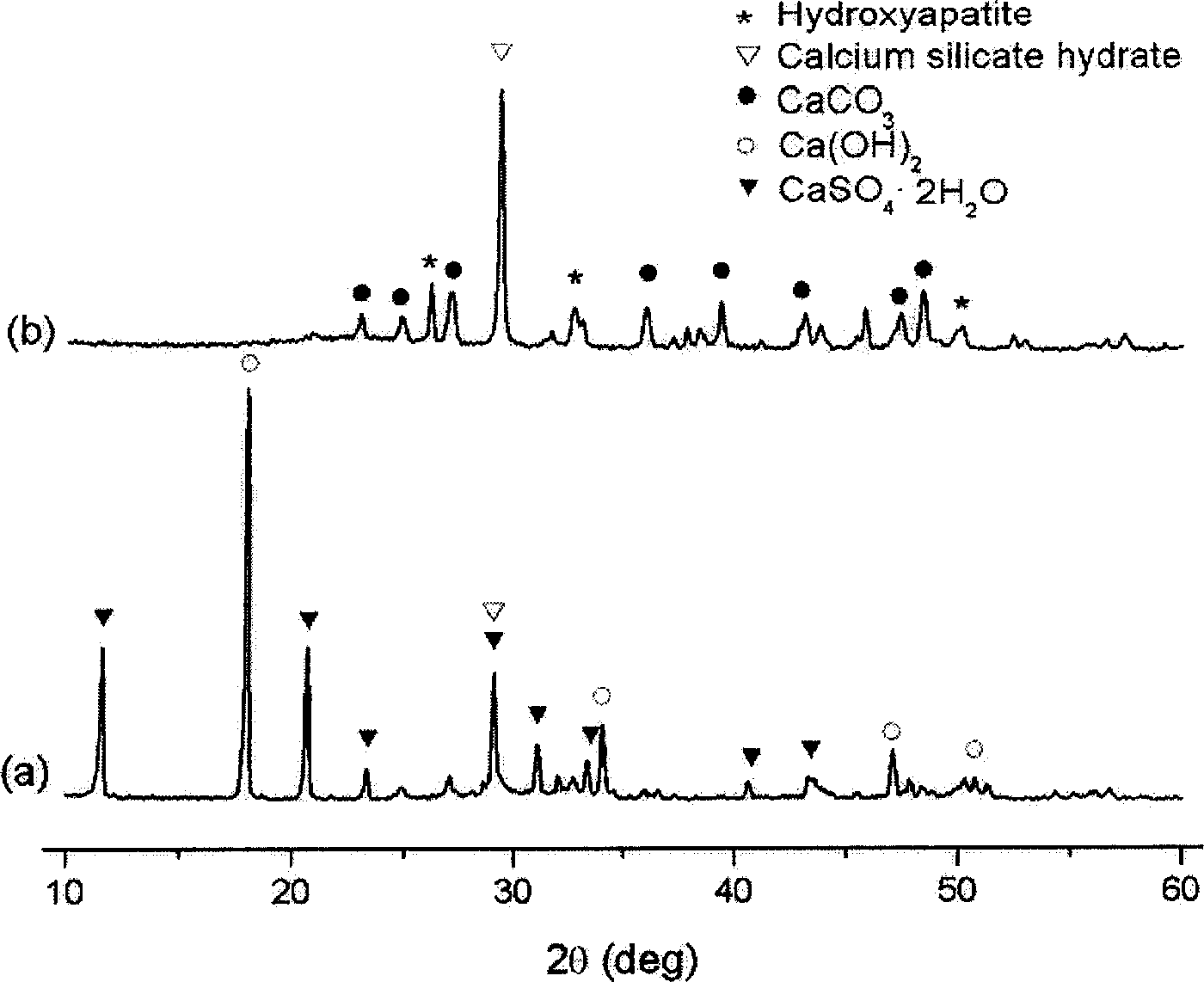

[0058] Tricalcium silicate and β-calcium sulfate hemihydrate are mixed in a mass ratio of 70:30 (the content of β-calcium sulfate hemihydrate is 30%) to obtain tricalcium silicate / β-calcium sulfate hemihydrate composite powder. The composite powder and the blending liquid are blended for 0.5-1 minute according to the liquid-solid mass ratio of 1:1, and the tricalcium silicate / β-calcium sulfate hemihydrate composite self-curing material is obtained. figure 1 For this reason, the XRD pattern of the composite self-curing material after curing for 7 days, L / P=1.0, it can be seen from the figure that the cured material contains calcium sulfate dihydrate a...

Embodiment 3

[0060] 1) Blending liquid preparation

[0061] Prepare 2L of simulated body fluid, place it in a plastic bottle, and store it at 5-10°C.

[0062] 2) Preparation of tricalcium silicate / α-calcium sulfate hemihydrate composite self-curing material:

[0063] Tricalcium silicate and α-calcium sulfate hemihydrate are mixed in a mass ratio of 7:3 (the content of α-calcium sulfate hemihydrate is 30%) to obtain tricalcium silicate / α-calcium sulfate hemihydrate composite powder. The composite powder and the simulated body fluid are mixed for 0.5-1 minute according to the liquid-solid mass ratio of 1:1 to obtain the tricalcium silicate / α-calcium sulfate hemihydrate composite self-curing material. This material has good injectability, the initial setting time and final setting time are 20 minutes and 35 minutes respectively; after curing for 28 days, the compressive strength is 51MPa. The material can be injected and has both mechanical strength and is suitable for oral cavity and minim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com