Preparation method of special material for injection moulding composite silicon rubber insulator mixing refine rubber

A technology of injection molding compounding and silicone rubber insulation, applied in the field of preparation of silicone rubber insulators, can solve problems such as adverse effects on physical and mechanical properties, affecting the storage period of mixed rubber, etc. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

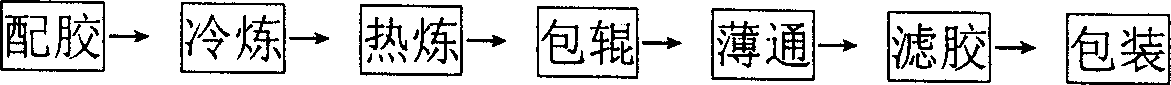

Method used

Image

Examples

Embodiment 1

[0018] The basic silicone rubber was prepared by using KOH as a catalyst to produce methyl vinyl high temperature rubber through vacuum dehydration and secondary dehydration process.

[0019] Preparation of flame-retardant filler aluminum hydroxide micropowder, wherein methyl phenyl hydroxy silicone oil is used as a high temperature resistant dispersant, vinyl triethoxysilane is used as a reinforcing agent for filler treatment, and the treatment method is: 100 parts of aluminum hydroxide, methyl 0.5-1.5 parts of phenylhydroxy silicone oil, 0.5-1.5 parts of vinyl triethoxysilane, the three raw materials are measured and added to a high-speed kneader, heated to 150°C with steam, and stirred for 2 hours.

[0020] According to the following formula: 100 parts of methyl vinyl high temperature adhesive; 25 parts of white carbon black; 5 parts of structure control agent hydroxyl silicone oil; 0.1 part of release agent; 120 parts of aluminum hydroxide; 3 parts of iron oxide red; 0.4 pa...

Embodiment 2

[0022] Prepare basic silicone rubber, flame retardant filler aluminum hydroxide micropowder with the same example as in Example 1, and then according to the following formula, 100 parts of methyl vinyl high temperature glue; 40 parts of white carbon black; 6 parts of structural control agent hydroxyl silicone oil; 0.2 parts of release agent 110 parts of aluminum hydroxide; 3 parts of iron oxide red; 0.4 parts of vulcanizing agent. Add 100 kg of methyl vinyl high-temperature adhesive and 0.2 kg of release agent into a 500L kneader. After turning on the machine and stirring evenly, add 40 kg in two For fumed silica, add 25 kg and 15 kg each time, and the interval time is based on the initial molding of the rubber material after stirring. At the same time, 6 kg of structuring control agent hydroxy silicone oil was added, and after stirring and molding, the temperature was raised to 170° C. for 1 hour, and then vacuumed for 0.5 hour, and the material was discharged and cooled. Aft...

Embodiment 3

[0024] Prepare basic silicone rubber and flame-retardant filler aluminum hydroxide micropowder with the same example as in Example 1, and then follow the following formula, 100 parts of methyl vinyl high-temperature glue; 35 parts of white carbon black; 6 parts of structural control agent hydroxyl silicone oil; 0.3 parts of mold release agent 115 parts of aluminum hydroxide; 3 parts of iron oxide red; 0.4 parts of vulcanizing agent. Add 100 kg of methyl vinyl high-temperature glue and 0.3 kg of mold release agent into a 500L kneader. After turning on the machine and stirring evenly, add 35 kg of fumed silica three times, adding 20 kg, 10 kg, and 10 kg each time. The interval time is subject to the initial molding of the rubber material after stirring. At the same time, 6 kg of structuring control agent hydroxy silicone oil was added, and after stirring and molding, the temperature was raised to 165°C for 1 hour, and then vacuumed for 0.5 hour, and the material was discharged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com