Vacuum cylinder for producing cystosepiment

A sheet production and vacuum cylinder technology, which is applied to the field of vacuum cylinders for foam sheet production, can solve the problems that foam sheet products cannot be fully and effectively foamed, affect the thermal insulation performance of products, and the density of foam sheets is high, and achieves low density and high cell size. Uniform density and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

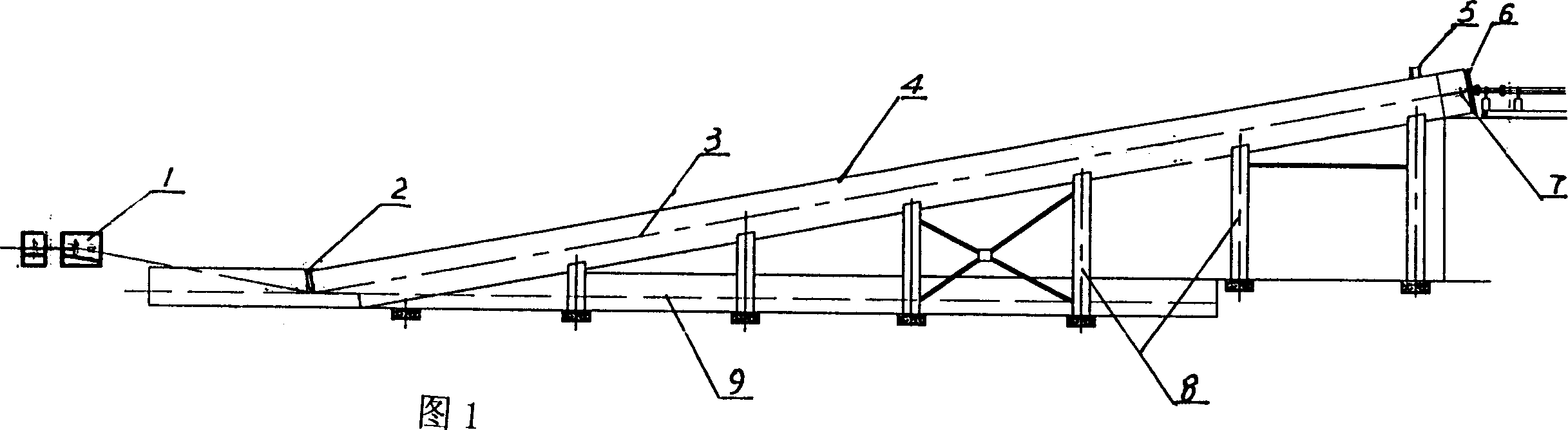

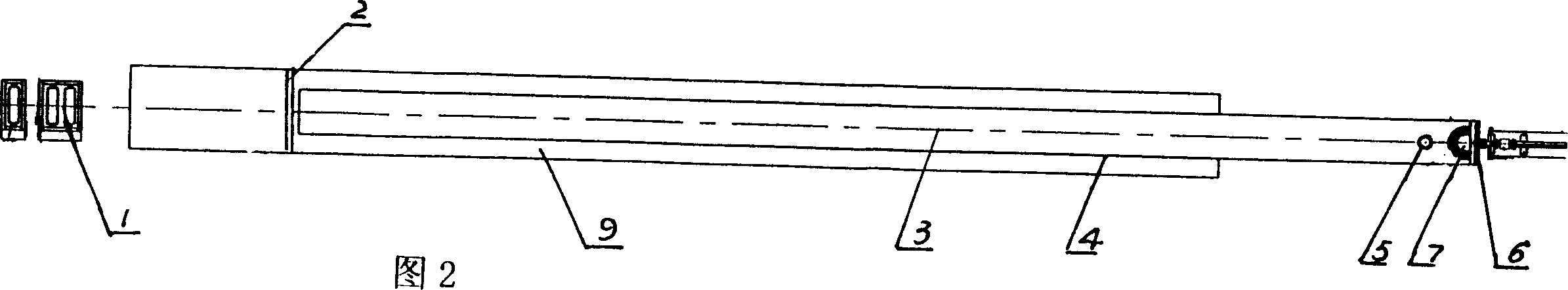

[0010] With reference to accompanying drawing 1~2, the structure of the vacuum cylinder used for foam board production comprises vacuum cylinder 4, conveyer belt 3, support column 8, water tank 9, conveyer belt 3 is arranged in the vacuum cylinder 4, and support column 8 is housed in the vacuum cylinder 4 bottom, The vacuum cylinder 4 is obliquely installed on the support column 8, the height difference between the high position and the low position is 2-10 meters, the upper part of the vacuum cylinder 4 is provided with a vacuum suction port 5, the vacuum suction port 5 is connected with the vacuum pump, and the lower part of the vacuum cylinder 4 is equipped with a water tank 9 , the vacuum cylinder 4 communicates with the water tank 9, a water seal baffle 2 is provided in the low vacuum cylinder 4, a vacuum sealing plate 6 is installed at the high end of the vacuum cylinder 4, the high position of the vacuum cylinder 4 is the entrance of the foaming plate, and the low positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com