Carbon-based fuel cell

A fuel cell, organic fuel technology, used in fuel cells, battery electrodes, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] exist image 3 In , a test assembly comprising a fuel cell 10 of the present invention is shown. The fuel cell 10 consists of a dense disc of YSZ (from Tosoh Corp.) coated with a thin layer of anode and cathode catalyst material to form the electrodes 12,14. Detailed steps involved in catalyst preparation and fuel cell 10 construction are explained in Example 2.

[0045] By having interface and Labview TM The software PC 50 obtains current and voltage output data from the fuel cell 10 . Gaseous exhaust products were analyzed by an SRI 8610C gas chromatograph54 and a Pfeiffer QMS200 mass spectrometer56. Analysis of gaseous products such as CO and CO2 allows determination of fuel conversion efficiency and by-product formation.

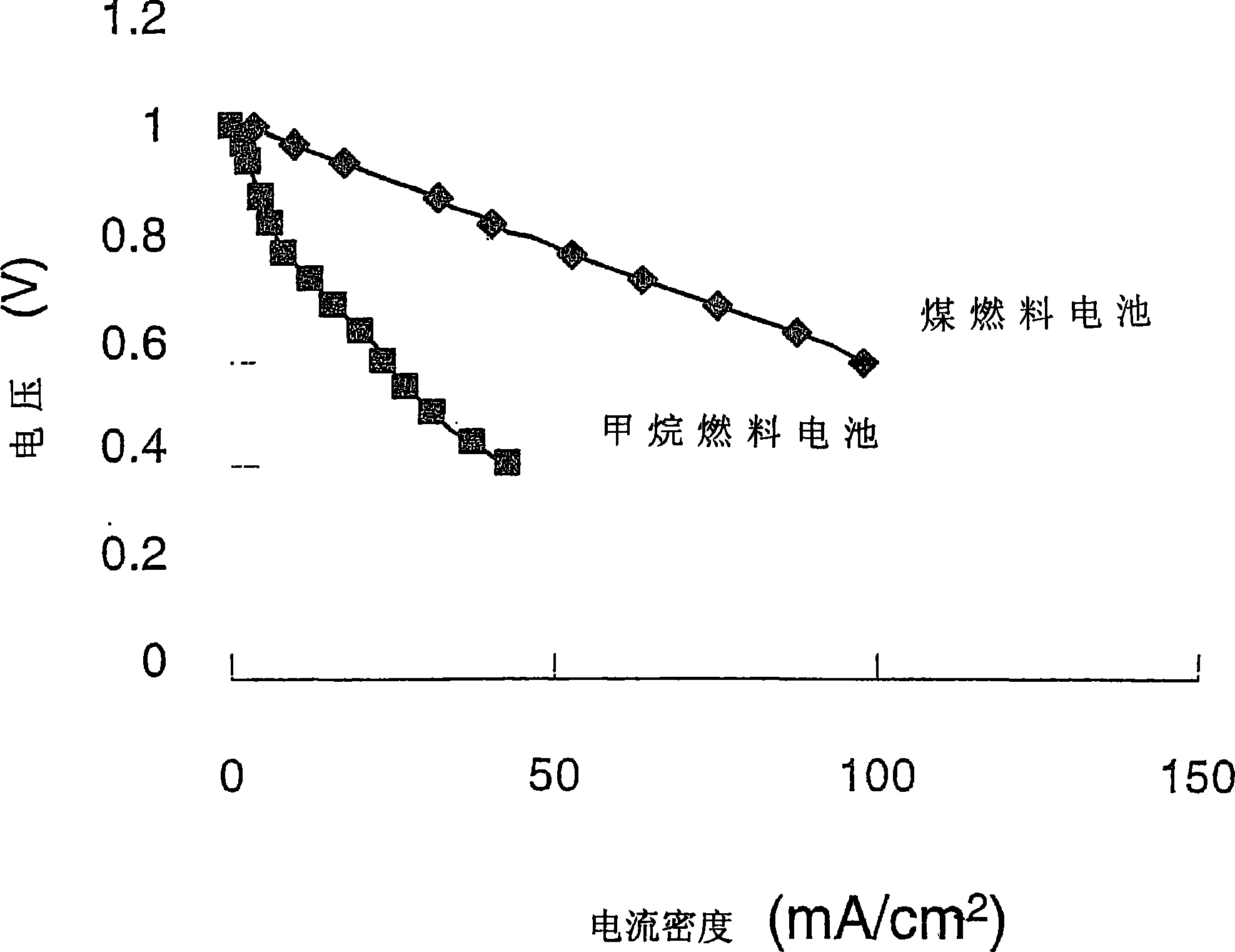

[0046] refer again figure 2 , shows the use of pure CH 4 Performance (I-V curves) of fuel cell 10 fueled with Ohio No. 5 coal (Table 1). Using coal as solid organic fuel, the coal is loaded into the tubular box 24 through the inlet 25 and ...

Embodiment 2

[0075] A YSZ disk (YSZ disk) with a thickness of 1 mm was purchased from Tosoh Inc. and used as the solid oxide electrolyte 18 . Ni(NO 3 ) 2 and NH 4 ReO 4 Impregnation prepares the materials that form the anode 14 and electrochemical oxidation catalyst assembly. The nominal weight percents of Ni and Re on the anode material are 5wt% (wt% means weight percent) and 2wt%, respectively. The anode / electrochemical oxidation catalyst material was pasted on the surface of a YSZ disc (1000 microns) with glycerin and calcined at 1000°C for 4 hours. This procedural process is repeated twice for making the thin layer forming the anode 14 .

[0054] A first electrode material was prepared by mixing lanthanum strontium manganese oxide (LSM-20, NexTech Materials) with YSZ powder in a 1:1 ratio. The cathode 12 was formed by pasting this first electrode material on a YSZ disc using glycerin, and calcined at 950° C. for 4 hours.

Solid Oxide Fuel Cell Assembly

[0055] Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com