Pump capable of eliminating air resistor

A technology of air resistance and vacuum pumps, which is applied to pumps, parts of pumping devices for elastic fluids, and drive pumps, etc. It can solve the problems of complex pumps and inconvenient clutch operating mechanisms, and achieve simple and reliable control, small size, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention is further described in detail.

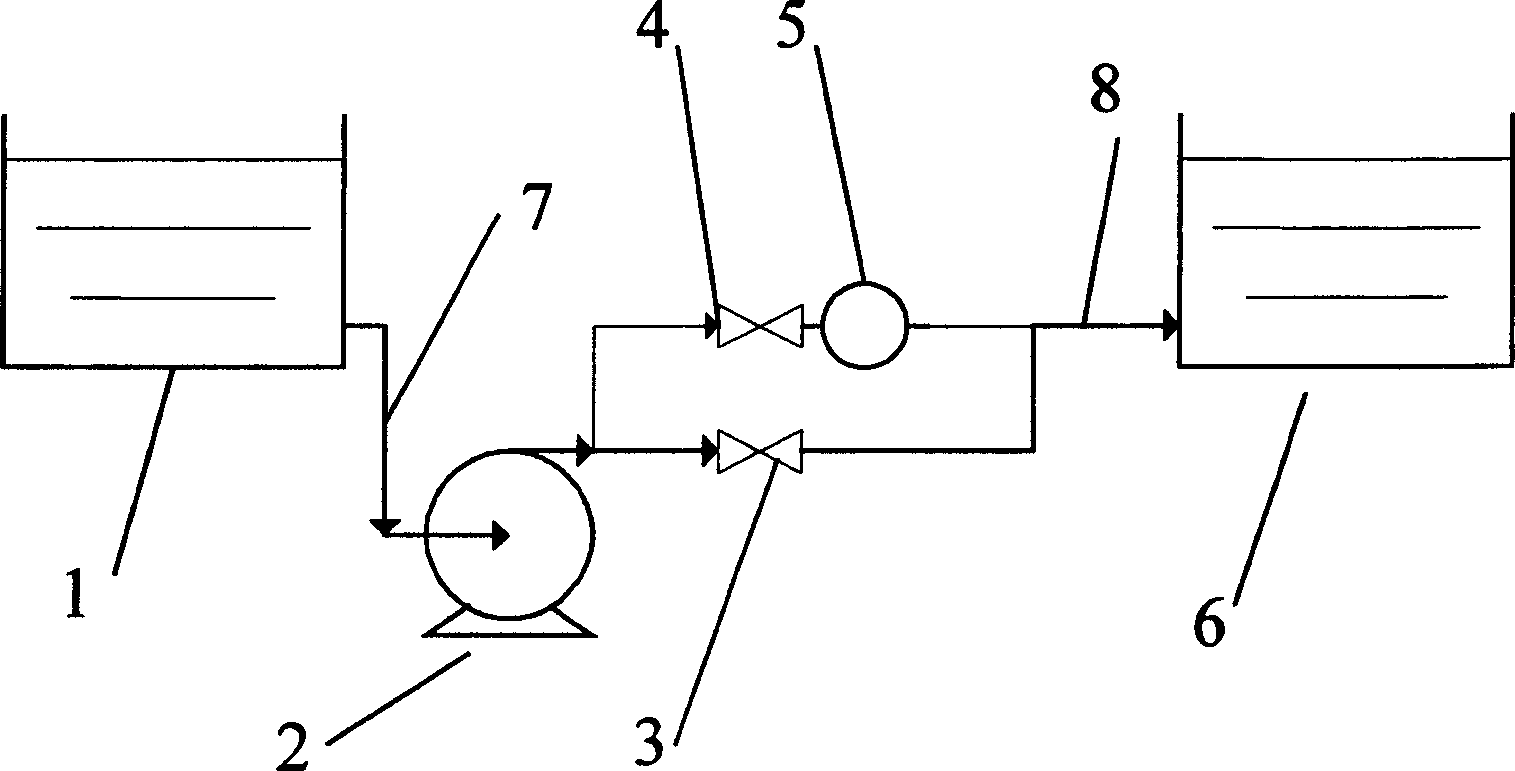

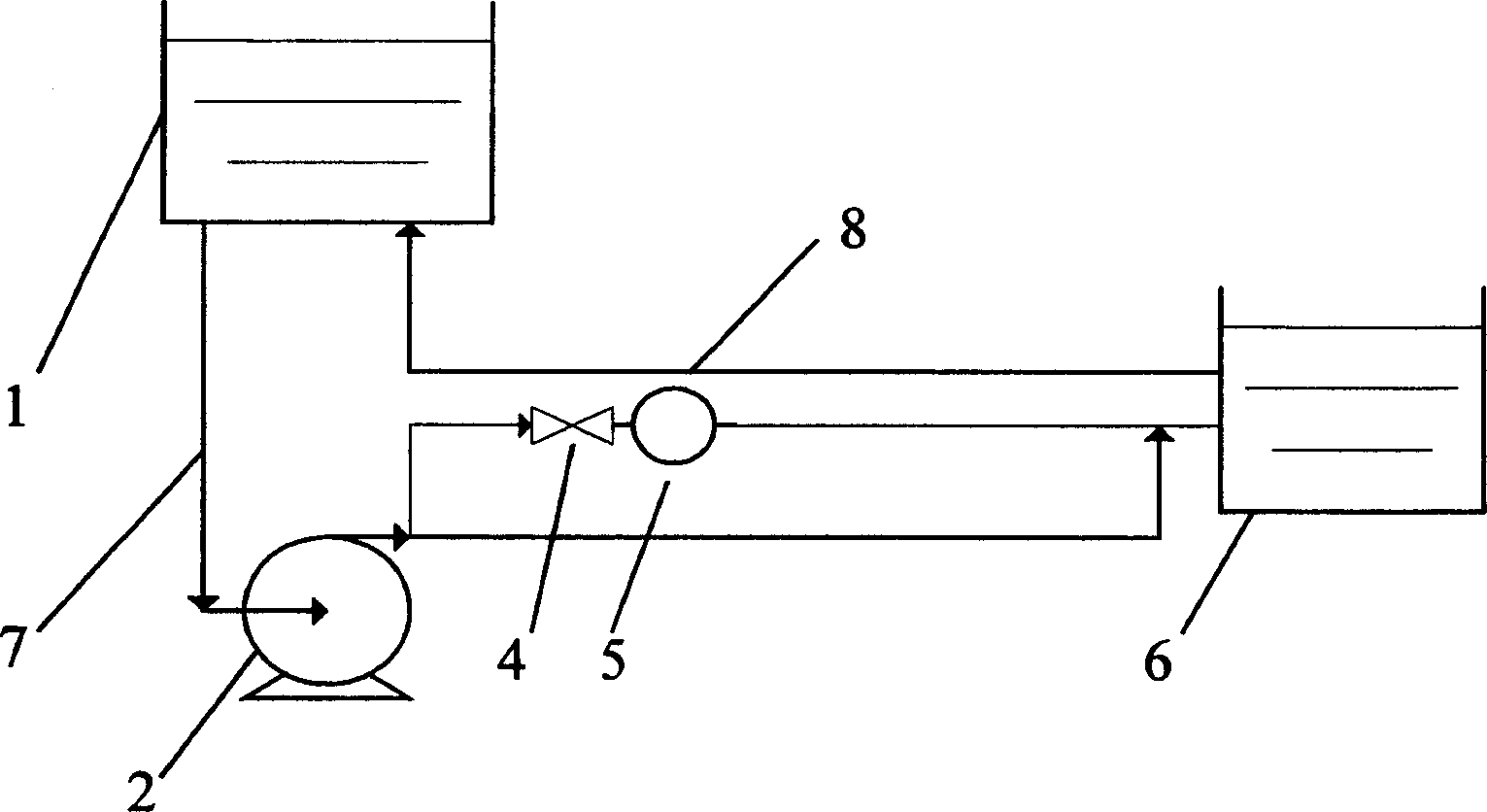

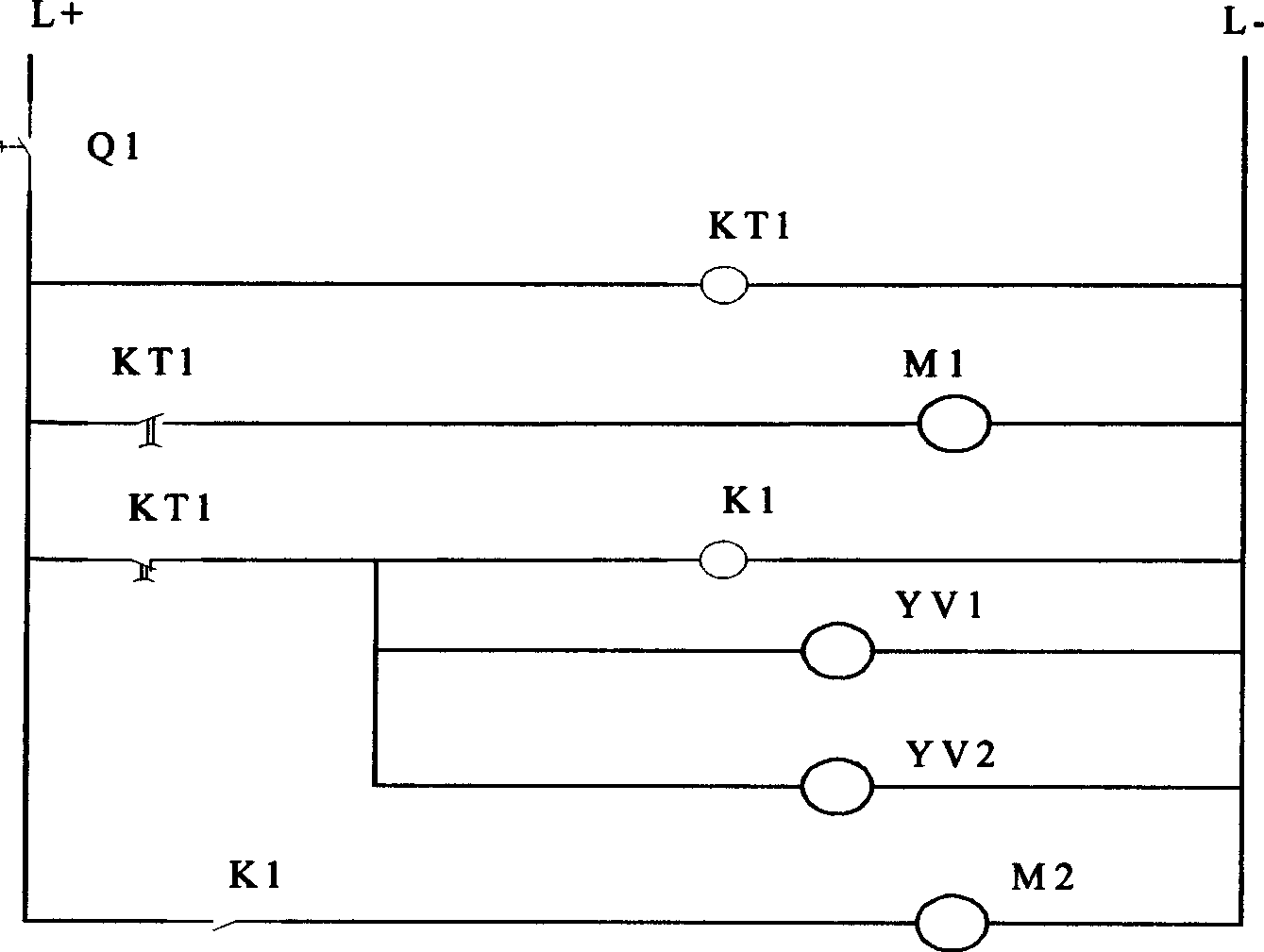

[0017] Such as figure 2 As shown, in this embodiment, the combined pump device includes a water tank 1, a pump 2, a vacuum pump 5, a water tank 6, and a control circuit. The inlet and outlet of the pump 2 are connected to the water inlet pipe 7 and the water outlet pipe 8 respectively, and the water inlet pipe 7 and the water outlet pipe 8 are respectively connected to the water tank 1 and the water tank 6, wherein the pump 2 is a magnetic pump, and the vacuum pump 5 is a micro vacuum pump. Because the waterway in this embodiment is a circulating waterway, the water tank 6 communicates with the water tank 1, and the water outlet pipe 8 is connected in parallel with a miniature vacuum pump M2. The water inlet pipe of the vacuum pump 5 is connected with a solenoid valve YV 1 3. The solenoid valve YV 1 The circuit of 3 is connected in parallel with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com