Cosmetic sheet

A patch and adhesive layer technology, which is applied in the direction of cosmetic preparations, dressing preparations, bone diseases, etc., can solve the problem of unsatisfactory removal of keratinized plugs, insufficient removal of keratinized plugs, and inability to satisfy users. issues such as high demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

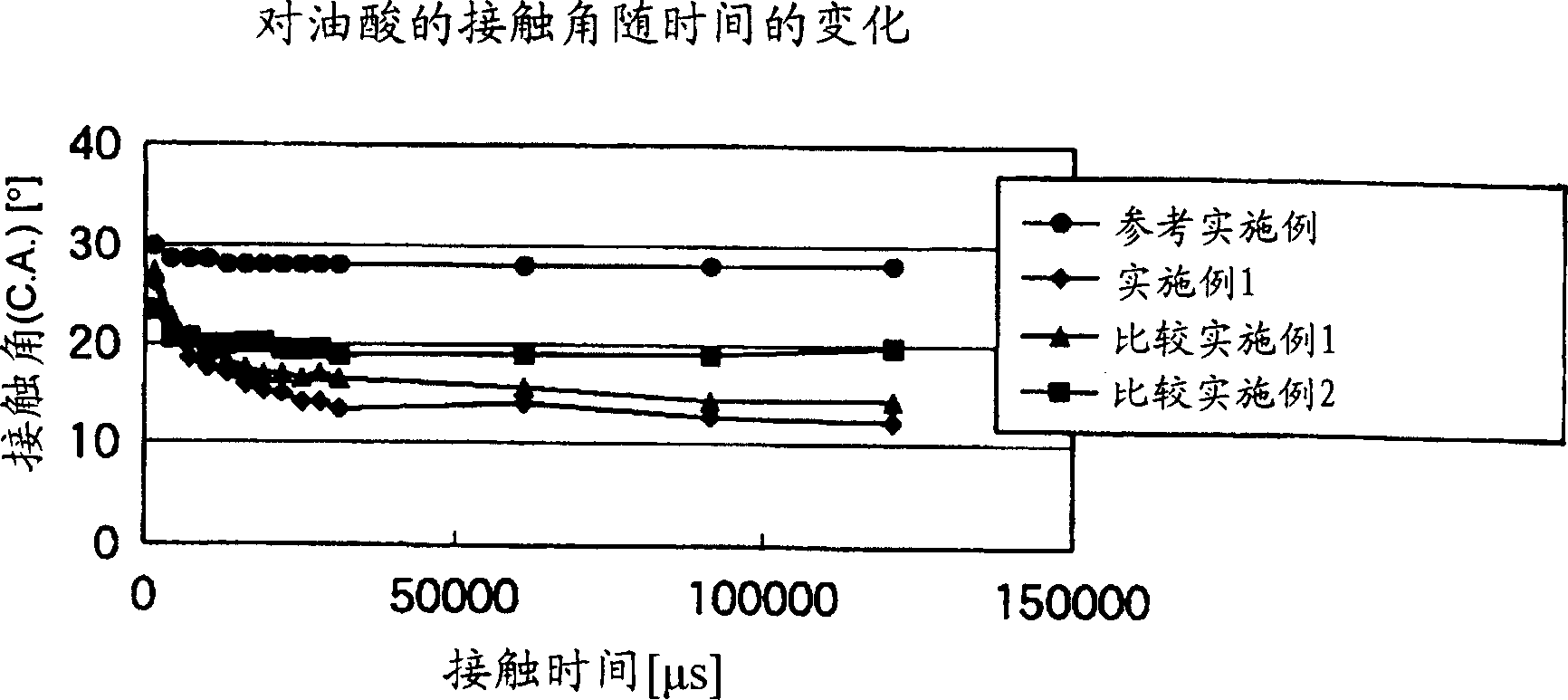

Embodiment 1

[0074] Use 58% by weight of polyvinylpyrrolidone with a weight average molecular weight of 1,200,000 as the water-soluble polymer, and 6% by weight of sorbitan oleic acid monoester (20 mol adduct of ethylene oxide, HLB15.0) as the polyoxyethylene oxide Sorbitan fatty acid ester, 34% by weight of silicic anhydride, and 2% by weight of titanium oxide, these compounds were stirred and mixed with an appropriate amount of purified water to prepare a coating solution. The coating solution was applied on the release-treated surface of a polyethylene film (thickness 50 μm), one surface of which had been treated with polysiloxane, thereby obtaining 110 g / m 2 The application amount and uniform thickness, thus forming a skin adhesive layer. Spunlaced non-woven fabric made of polyester fibers (unit weight: 40g / m 2 ) was covered on the skin adhesive layer, and then the whole was dried at 105° C. for 3 minutes to prepare a cosmetic patch with a three-layer structure. In the resulting cosm...

Embodiment 2

[0101] Use 56% by weight of polyvinylpyrrolidone with a weight-average molecular weight of 1,200,000 as the water-soluble polymer, and 6% by weight of sorbitan oleic acid monoester (20 mol adduct of ethylene oxide, HLB15.0) as the polyoxyethylene oxide Sorbitan fatty acid ester, 34% by weight of silicic anhydride, 1% by weight of titanium oxide, and 3% by weight of medicinal carbon. These compounds and an appropriate amount of purified water were stirred and mixed to prepare a coating solution. The coating solution was coated on the release-treated surface of polyethylene film (thickness 50 μm) whose surface had been treated with polysiloxane to obtain 110 g / m 2 The application amount and uniform thickness, thus forming a skin adhesive layer. Spunlaced non-woven fabric made of polyester fibers (unit weight: 40g / m 2 ) was covered on the skin adhesive layer, and then the whole was dried at 105° C. for 3 minutes to prepare a cosmetic patch with a three-layer structure. In the ...

Embodiment 3

[0116] Use 58% by weight of polyvinylpyrrolidone with a weight average molecular weight of 1,200,000 as the water-soluble polymer, and 6% by weight of sorbitan oleic acid monoester (20 mol adduct of ethylene oxide, HLB15.0) as the polyoxyethylene oxide Sorbitan fatty acid ester, 34% by weight silicic anhydride, and 2% by weight titanium oxide. These compounds and an appropriate amount of purified water were stirred and mixed to prepare a coating solution. The coating solution was coated on the release-treated surface of polyethylene film (thickness 50 μm) whose surface had been treated with polysiloxane to obtain 110 g / m 2 The application amount and uniform thickness, thus forming a skin adhesive layer. Spunlaced non-woven fabric made of polyester fibers (unit weight: 40g / m 2 ) was covered on the skin adhesive layer, and then the whole was dried at 105° C. for 1.5 minutes to prepare a cosmetic patch with a three-layer structure. In the obtained cosmetic patch, the water con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com