Micro air bubble generation device and method, water treatment device using the same

A technology of water treatment equipment and generation device, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of water treatment methods, changes in decompression, and changes in ozone dissolution efficiency without revealing the generation method of micro bubbles, so as to maintain the ozone dissolution efficiency , Improve the operation economy and improve the effect of water treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

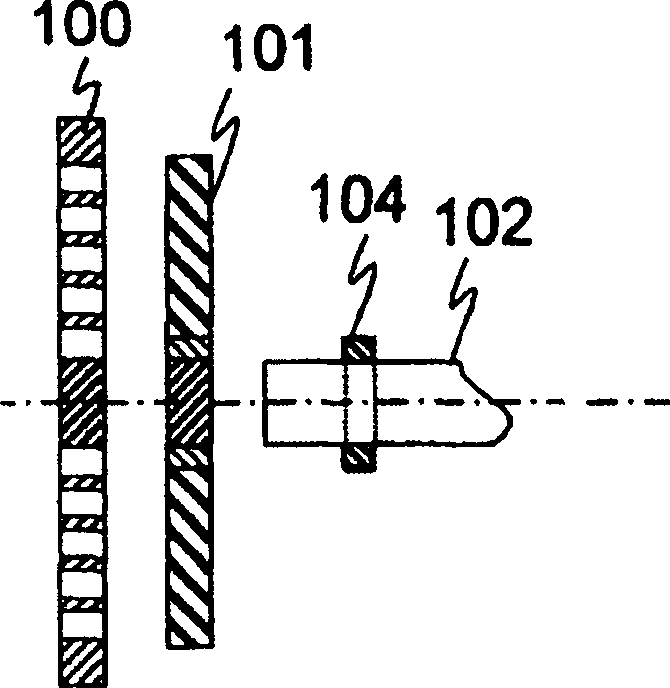

[0089] Below, refer to Figure 1 to Figure 12 Example 1 of the present invention will be described. figure 1 It is a configuration diagram of the microbubble generating device of this embodiment.

[0090] The micro-bubble generating device of the present embodiment, such as figure 1 As shown, the flow path 9a connected to the gas-liquid two-phase flow generating device not shown, the pump 1 connected to the flow path 9a, the converter not shown connected to the pump 1, the flow path 9b and the The perforated plate assembly 4 connected to the pump 1, the pressure gauge 5 provided on the flow path 9b, the driving device 7 provided on the perforated plate assembly 4, the flow path 9c connected to the perforated plate assembly 4, the pressure gauge 5 provided on the flow path 9c The flow meter 6 above, the control device 3, and the input device 8 connected to the control device 3 constitute. Here, in the gas-liquid two-phase flow, the liquid is water, and the gas is any one of ...

Embodiment 2

[0119] Below, refer to Figure 13 to Figure 16 Example 2 of the present invention will be described. Figure 13 It is a configuration diagram of the microbubble generating device of this embodiment.

[0120]The microbubble generator of this example is configured in the same manner as in Example 1, however, in this example, a porous plate assembly 40 is used instead of the porous plate assembly 4 . The structure of the perforated plate assembly 40 is that, behind the pump 1 in the flow path 9b, several branch flow paths are provided, and the porous plates 40 respectively having a fixed number of holes are arranged on each branch flow path through valves 70-1 to 70-n. -1~40-n. The plurality of porous plates 40-1 to 40-n are connected to the flow path 9c after merging. The valves 70-1 to 70-n are respectively connected to the control device 3 through signal lines, and the opening and closing of the valves 70-1 to 70-n are controlled. Here, in the case where the flow path 9c c...

Embodiment 3

[0133] Below, refer to Figure 17 to Figure 23 Embodiment 3 of the present invention will be described. Figure 17 to Figure 23 is a configuration diagram of the perforated plate assembly in this example.

[0134] The perforated plate assembly of this embodiment is the one in Example 1 Figure 2 to Figure 6 A variation of the perforated plate assembly 4 is shown.

[0135] Such as Figure 17 to Figure 23 As shown in the perforated plate 210, the circular plate is divided into several regions, and holes with different pore diameters are formed in each region, that is, holes with different cross-sectional areas are provided in each region. Alternatively, holes of the same cross-sectional area may be provided in each region of the porous plate 210 so that the holes have the same diameter and the number of holes per unit surface area is different. The flow path restricting plates are arranged on both sides of the porous plate 210, the semicircular flow path restricting plate 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com