Etching solution, method of etching and printed wiring board

An etching solution and etching technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problem of not being able to obtain sufficient inhibition effect, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

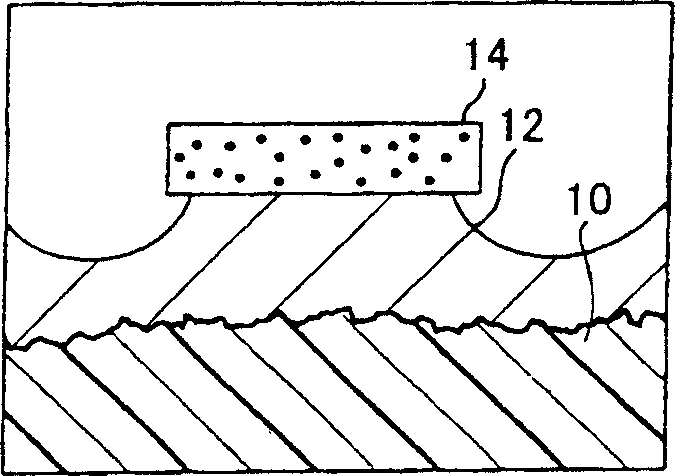

Image

Examples

Embodiment 1

[0158] (1) Preparation of etching solution

[0159] In the copper chloride solution (copper chloride copper ion concentration: 2 to 2.2 mol / L, hydrochloric acid: 2 to 3 mol / L), add 800 ppm of BTA (benzotriazole) as a BTA compound, and add it as an amphoteric surface Alkyldimethylaminoacetic acid betaine as an active agent and polyoxyethylene alkyl ether as a nonionic surfactant total 5000 ppm to prepare an etching solution.

[0160] When preparing this etching solution, first, add BTA (benzotriazole) as a BTA compound to a mixed aqueous solution of amphoteric surfactant and nonionic surfactant, and then stir until the BTA is completely dissolved in the surfactant containing In the aqueous solution, an additive is prepared accordingly, and then the additive is added to the copper chloride solution to prepare an etching solution.

[0161] (2) Formation of etching protection layer

[0162] A copper foil with a thickness of 70 μm for forming a copper wiring pattern is attached to one ...

Embodiment 2

[0178] A printed circuit board was manufactured in the same manner as in Example 1, except that an etching solution was prepared without adding a surfactant to the copper chloride solution, and the spray pressure in the etching conditions was 0.5 MPa to 0.6 MPa.

[0179] In addition, when preparing an etching solution, for example, a predetermined amount of BTA is added to a KOH aqueous solution of pH 13, and the solution is stirred until the BTA is completely dissolved in KOH, and the resulting solution is used as an additive. Then, the additive was added to the copper chloride solution to prepare an etching solution.

Embodiment 3

[0181] A printed circuit board was manufactured in the same manner as in Example 1, except that the concentration of BTA as a BTA-based compound in the copper chloride solution was 1005 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com