Method for projecting and screening microelectronic-packed tin ball

A screening method and tin ball technology, applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of low screening efficiency, multi-row overlap, low screening accuracy, etc., and achieve high screening efficiency, low probability of missed detection, The effect of high screening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

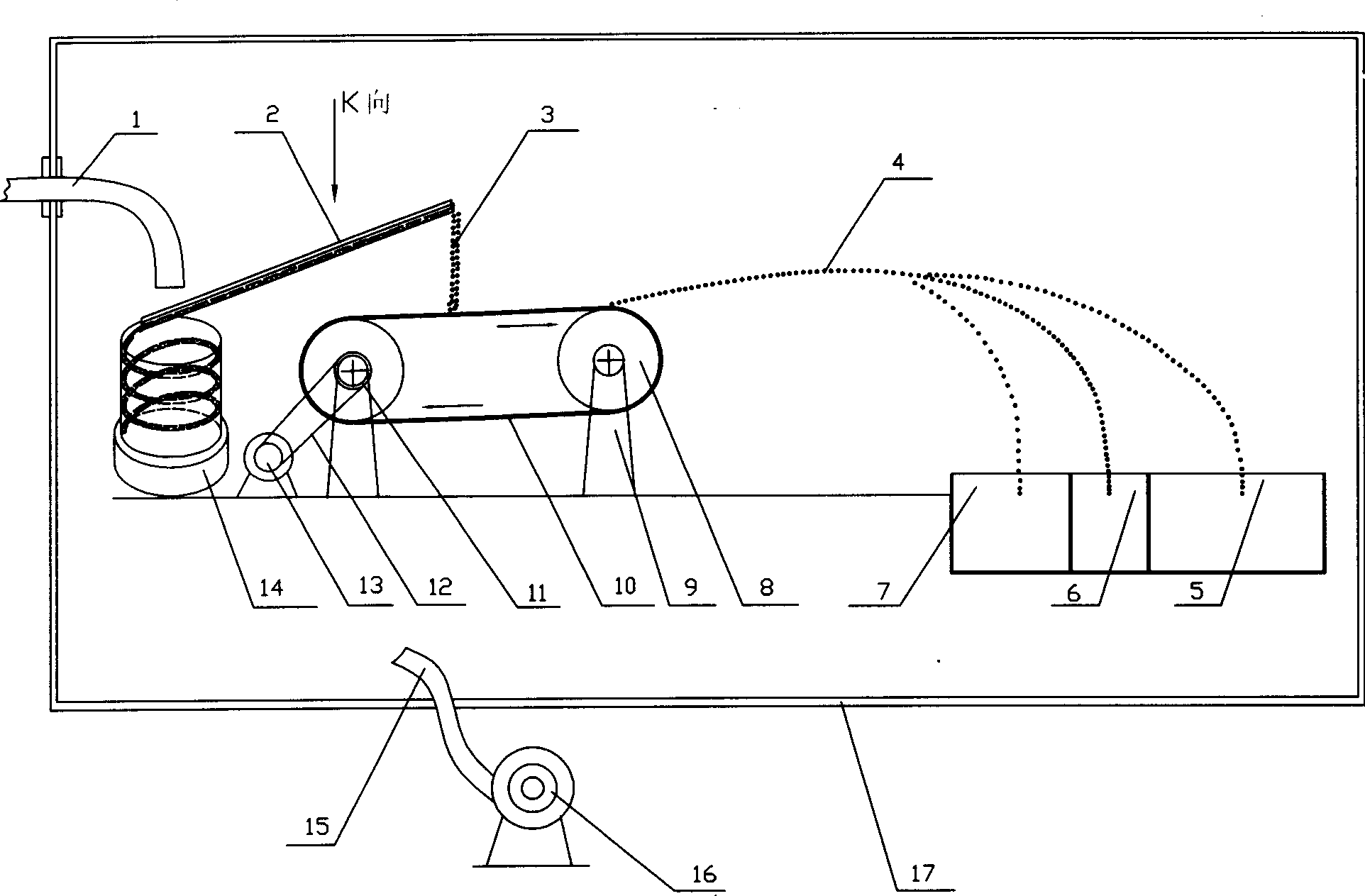

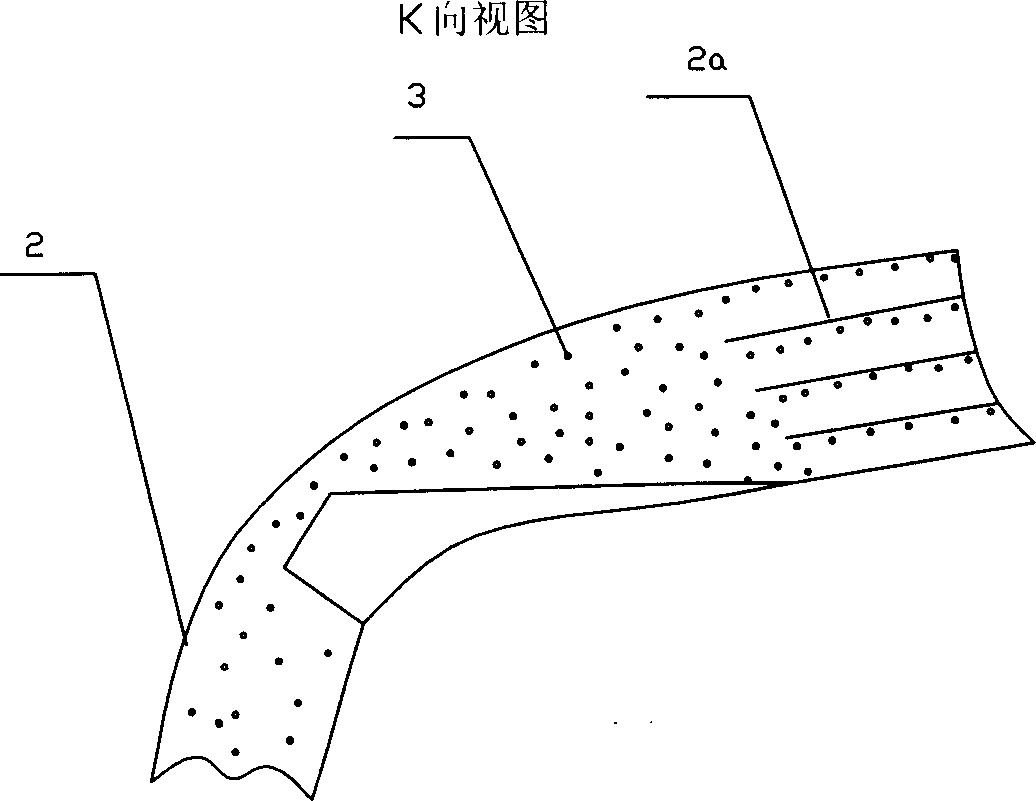

[0011] Embodiment 1: as figure 1 Shown, a mechanical vibrating screw feeding device 14 is set on the supporting surface in the vacuum cover 17, and vibrating feeding hopper 2 is connected above it, and the feeding hopper 2 is provided with sub-discharging passage 2a (as figure 2 shown), in order to make the solder balls 4 oscillate in a single row along the sorting channel 2a. Also be provided with a motor 13 and a pair of drive roller 8 on the support surface, drive roller 8 is connected on the support surface by support frame 9, the output shaft of motor 13 is connected with the synchronous pulley 11 on the drive roller by synchronous belt 12 Connection and cooperation, the transmission roller is connected with a conveyor belt 10, and the mouth of the feed hopper 2 is matched with the middle of the conveyor belt 10, so that the solder balls will not fall into the conveyor belt. The conveyor belt 10 can have a certain upward inclination angle, and the solder balls 3 is thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com