Selectivelly-desulfurized dense-phase tower drier

A selective, non-desulfurization technology, applied in the field of sintered pellets, which can solve the problems of reduced flue gas temperature and condensation, complicated configuration of auxiliary equipment, and large space occupation, so as to reduce energy consumption, save investment and space, and save operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

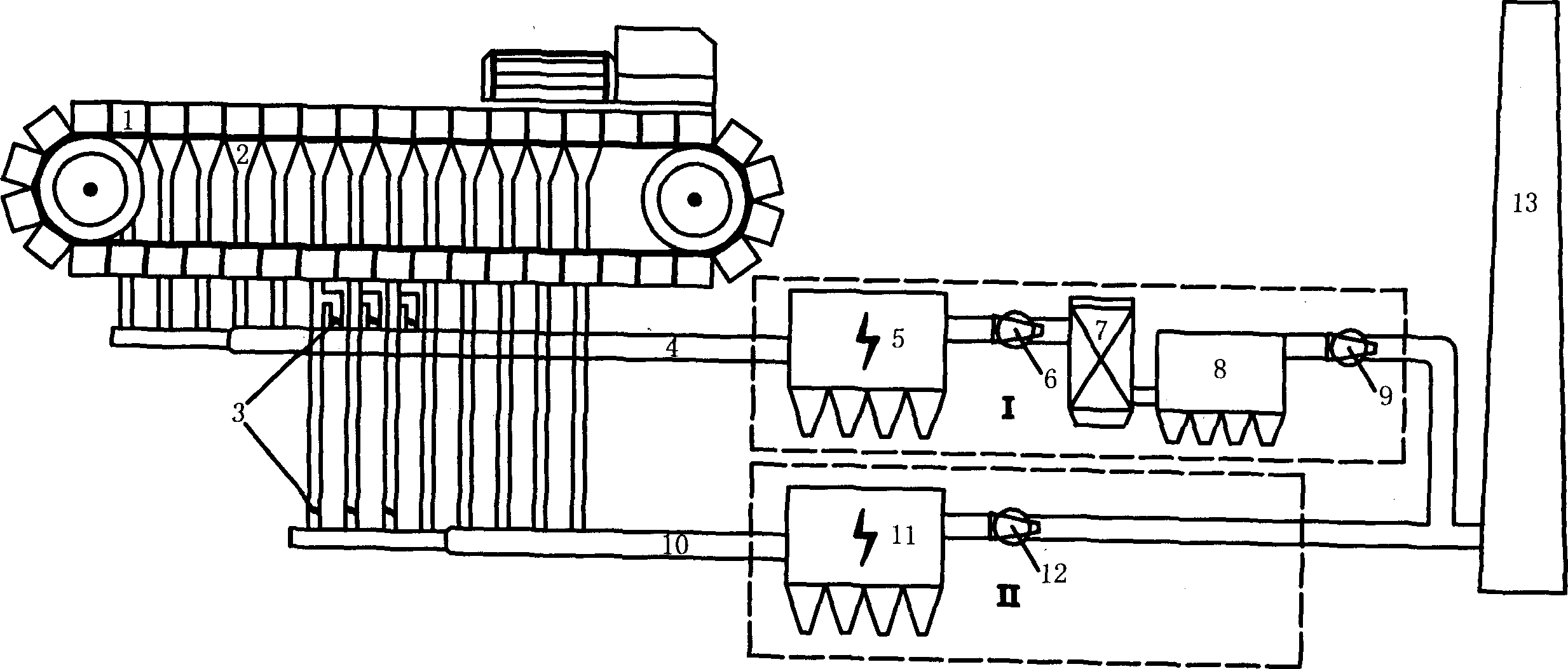

[0016] figure 1 It is a specific embodiment of the present invention. The flue gas produced by sintering machine 1 is divided into two parts, containing SO 2 The part with higher concentration enters the large flue 4 of the desulfurization system through the air collecting hopper 2 under the suction of the desulfurization system exhaust fan 6, and contains SO 2 The part with lower concentration enters the non-desulfurization large flue 10 through the air collecting hopper 2 under the suction effect of the non-desulfurization exhaust fan 12 . A flue flapper valve 3 is installed on the flue of the desulfurization system I and non-desulfurization system II, so that the flue gas can be switched between the desulfurization system I and the non-desulfurization system II to prepare for SO in the flue gas. 2 change in concentration. The desulfurized flue gas enters the desulfurization system electrostatic precipitator 5 through the large flue 4 of the desulfurization system, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com