High-activity coefficient active picture element image sensor structure and producing method threof

An image sensor and fill factor technology, which is applied in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve the problems of low fill factor, reduce stress damage, improve sensitivity and fill factor, and solve the problem of fill factor low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

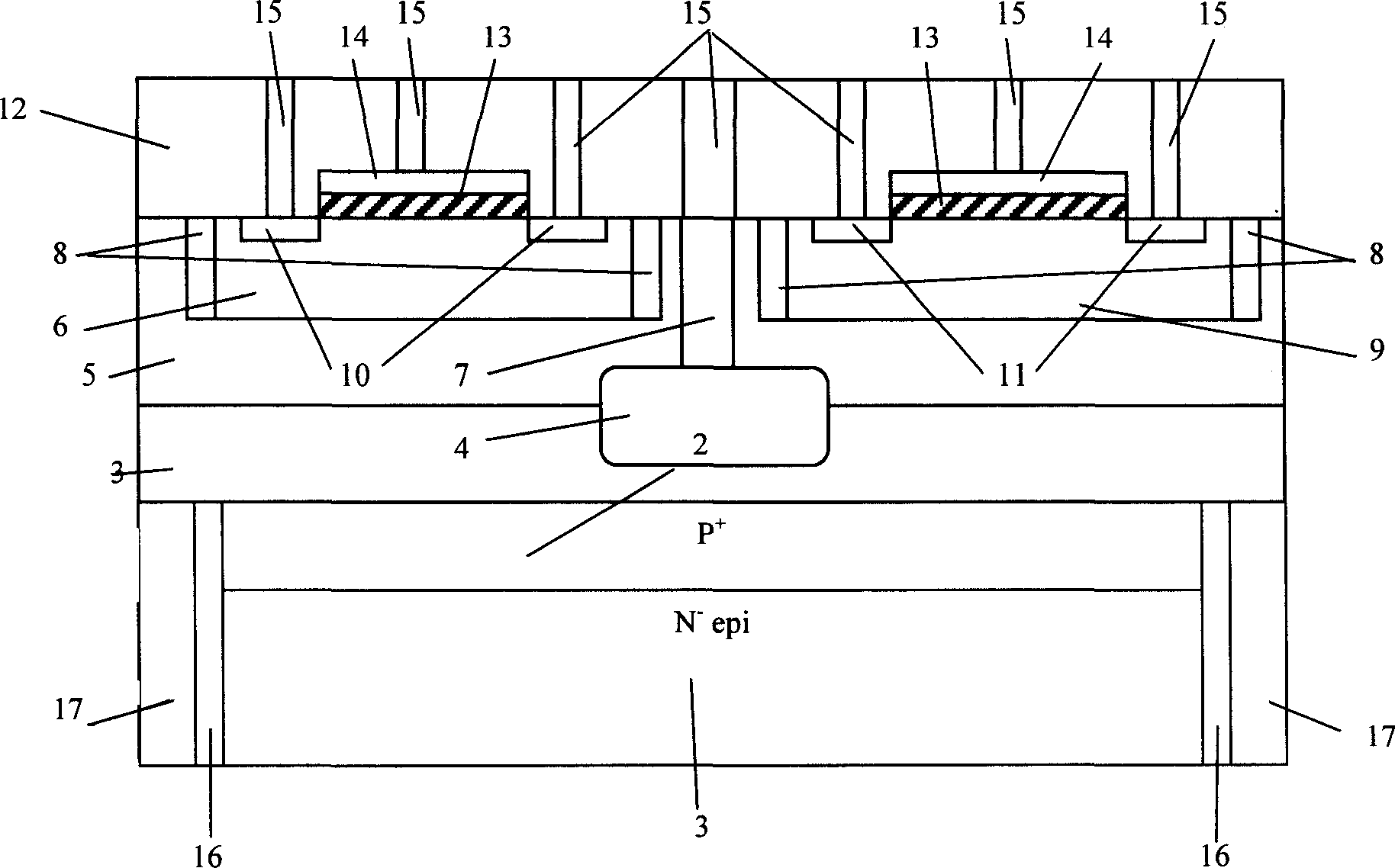

[0051] Specific embodiment two such as figure 1 Shown:

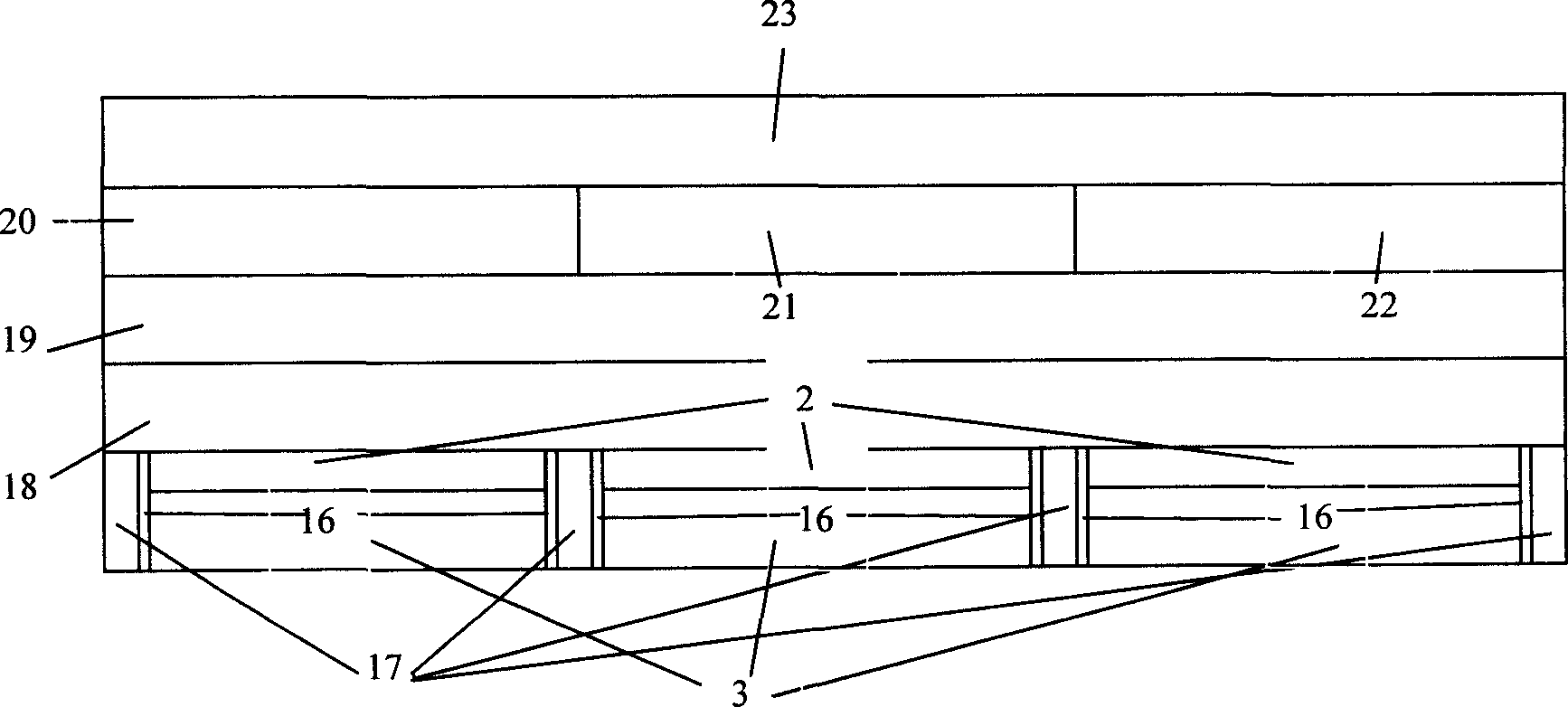

[0052] If the color pixel is different from the first embodiment, the silicon base is different from the upper structure of the P+ layer 2, and an ethyl silicate TEOS layer 18 and a silicon nitride SiN layer 19 can also be arranged in sequence on the P+ layer 2; A blue filter BCF layer 20 , a red filter RCF layer 21 and a green filter GCF layer 22 are arranged on the SiN layer; a photoresist PR layer 23 is arranged on the top.

[0053] The specific implementation manner of the process flow of the manufacturing method of the active pixel image sensor structure with high fill factor of the present invention is as follows, taking Embodiment 1 as an example:

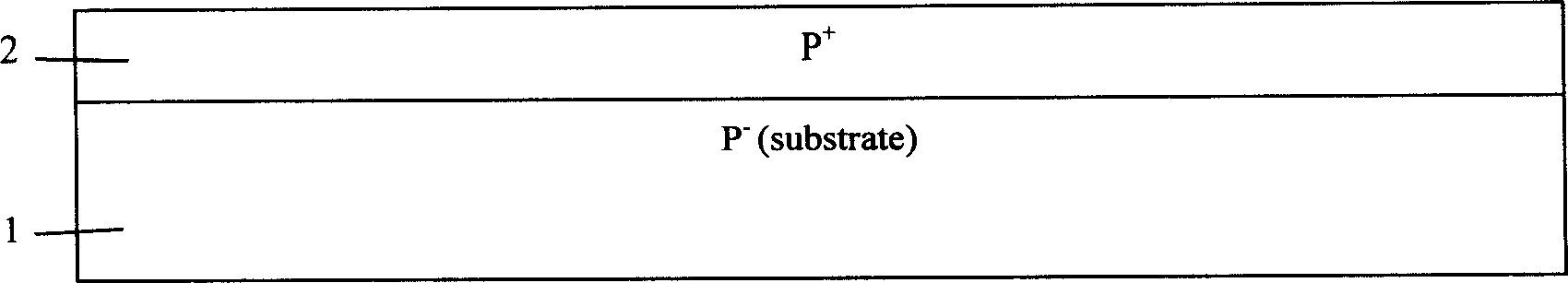

[0054] First, if image 3 As shown, on the P-substrate 1, a layer of SiO was grown by thermal oxygen 2 , with a thickness of 300 angstroms to 350 angstroms. The purpose is to reduce the damage of the P-substrate 1 by ion implantation, and at the same time reduce th...

Embodiment 2

[0060] The specific implementation method of the process flow of the manufacturing method of the active pixel of the second embodiment is as follows: figure 2 Shown on the P+ layer 2 is TEOS[Si(C 2 h 5 o 4 )] 18→SiN19→blue filter layer (BCF) 20→red filter layer (RCF) 21→green filter layer (GCF) 22→photoresist (PR) 23. Because of the high fill factor of this structure, microlenses may not be required.

[0061] The structure of the active pixel structure image sensor of the present invention makes full use of the two sides of the silicon base, wherein the back side is used to manufacture photodiodes for converting incident light into electrical signals, and the front side is used to manufacture signal processing circuits. The filling factor of the entire pixel array is close to 100%, thereby improving the quantum efficiency; and compared with the traditional CMOS image sensor structure, the invented active pixel structure image sensor can obtain a smaller dark area because o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com