Pneumatic and oil-burning mixed powder vehicle

A technology of hybrid electric vehicles and fuel oil, which is applied in the direction of hybrid electric vehicles, fluid hybrid electric vehicles, pneumatic power devices, etc., can solve the problems of high labor intensity, vehicle deviation, fuel waste, etc., and achieve strong road adaptability and reduce The effect of tire wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

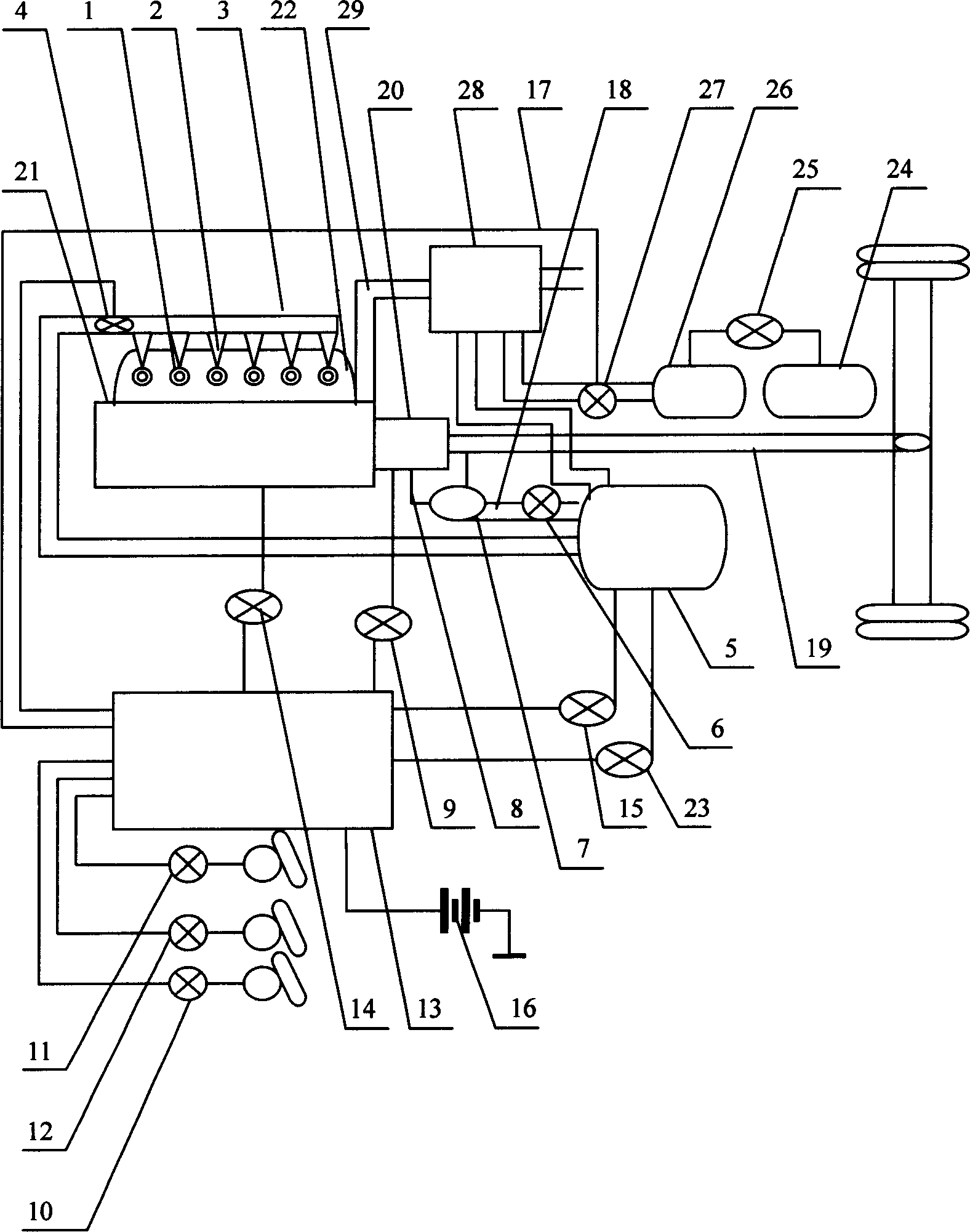

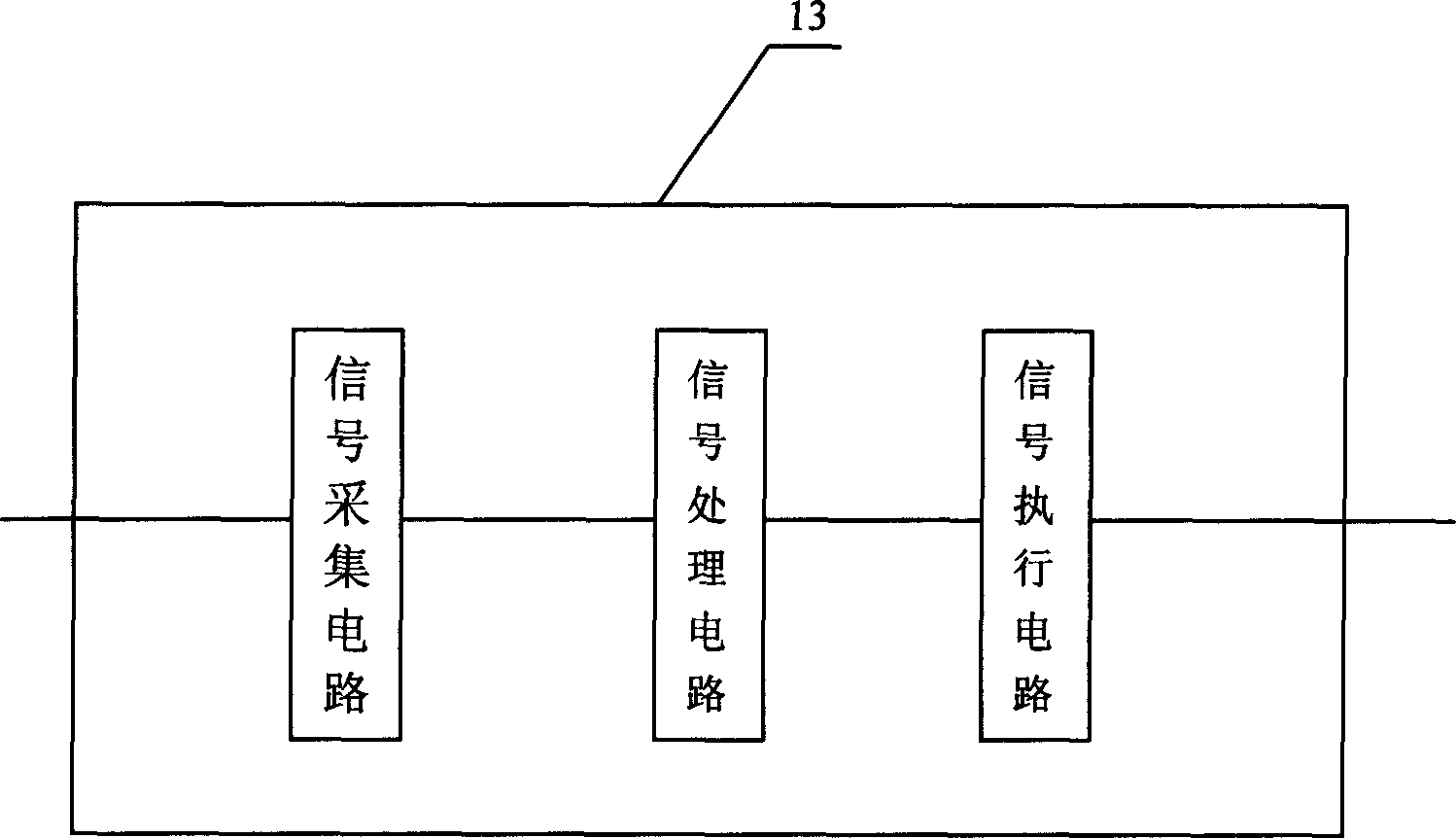

[0011] Depend on figure 1 Schematic diagram of the structure and figure 2 As can be seen from the block diagram of the signal processor, the present invention adds an exhaust check valve seat hole 1 at the corresponding positions of each cylinder head 22 of the engine 21, and the exhaust check valve seat hole 1 directly connects with each cylinder of the engine 21. Combustion chambers communicate. The one-way valve 2 is installed on the exhaust one-way valve seat hole 1, and the one-way valve 2 is connected to the electronically controlled high-pressure air valve 4 and the air storage tank 5 by the high-pressure air pipe 3; There are safety valve, one-way valve, drain valve, low air pressure sensor switch 15 and high air pressure sensor switch 23. A pressure regulating overflow valve 25 is provided on the vehicle brake air source storage tank 24 and is connected to the water storage tank 26 through a pipe. The water storage tank 26 is installed on the vehicle frame and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com