Crystal quick growth device using solution method

A growth device and solution method technology, which is applied in the field of solution method crystal rapid growth device, can solve the problems of strong convection effect, difficulty in forming, affecting crystal quality, etc., and achieve the effect of fast crystal growth speed, convenient use and operation, and simple structure principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

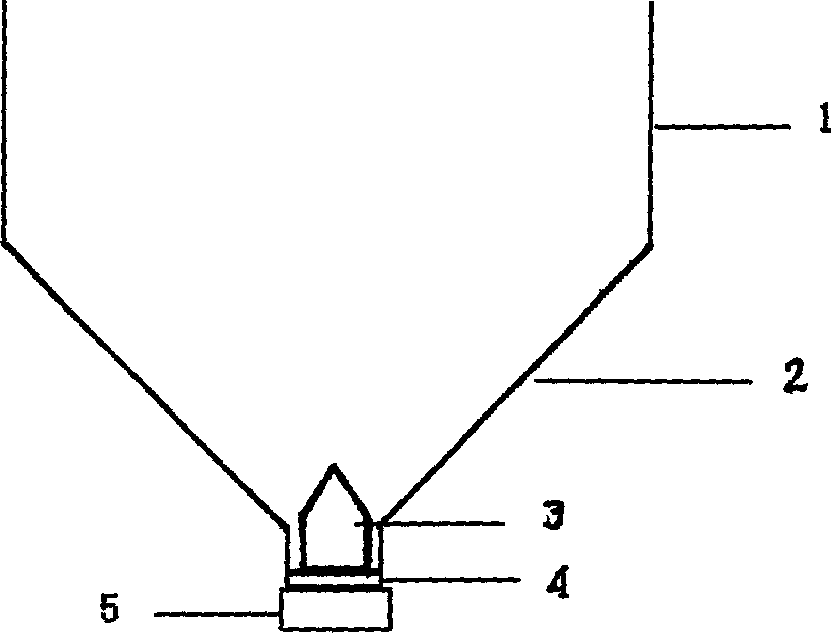

[0008] During the implementation of the present invention, a crystal growth cylinder is designed and formed on the technical basis of growing crystals by solution cooling method, and its main structure includes a cylindrical cylinder wall 1, a conical cylinder wall 2, a conical top glass cylinder 3, a circular cylinder bottom 4 and The heating plate 5 at the bottom of the cylinder is processed and manufactured to form a cylindrical cylinder type glass growth vessel (cylinder) with a conical bottom (cone facing downwards). The bottom of the growth container of the cylinder type structure is that the cone top is made with a flat-bottomed circular cylinder bottom 4, and the area of its flat bottom is relatively small, and the general diameter is 0.5~1.5cm, preferably 1.0cm. A solid conical top glass cylinder 3 is formed on the flat bottom of the circular tank bottom, the diameter of the cylinder should be 1.0-3.0mm smaller than the flat bottom diameter of the cylinder bottom, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com