A device for titanium metal oxycarburizing

A technology of oxycarburizing and titanium metal, which is applied in the field of titanium metal oxycarburizing devices and titanium surface hardening equipment, can solve the problems of limited improvement in wear resistance, affecting the performance of titanium alloy substrates, and shallow carburizing layers. Achieve the effect of guaranteeing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

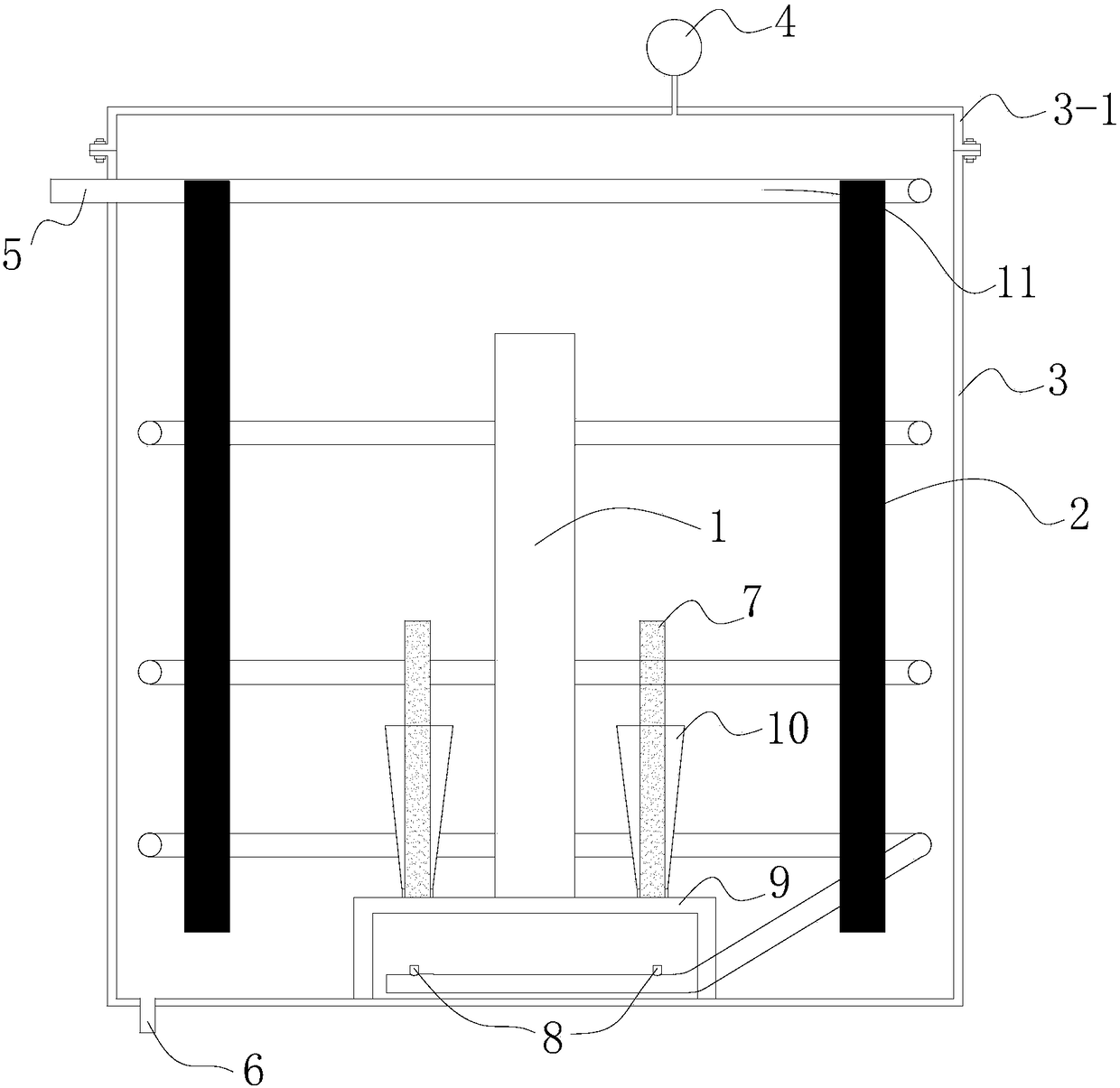

[0016] see figure 1 : The present invention is used for the device of titanium metal oxycarburizing, comprises vacuum chamber 3, and described vacuum chamber 3 top is provided with air inlet 5 and pressure gauge 4, and the bottom of vacuum chamber 3 is provided with pump group 6, is characterized in that , the vacuum chamber 3 is also provided with a heating element 2; the inner wall of the vacuum chamber 3 is coiled with an intake air preheating pipe 11 communicating with the air inlet 5, and the air intake preheating pipe 11 comes from the vacuum chamber 3, the air inlet 5 on the top of the vacuum chamber circles downwards in a circle around the inner wall of the vacuum chamber, and the air intake preheating pipe 11 circles to the bottom of the vacuum chamber 3, and the air outlet of the air intake preheating pipe 11 is arranged below the material rack 9. Titanium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com