High length-diameter ratio titania nanometer tube array preparation method

A technology of nanotube array and high aspect ratio, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of long anodic oxidation time, achieve uniform distribution, increase electrochemical reaction speed, and fast growth rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

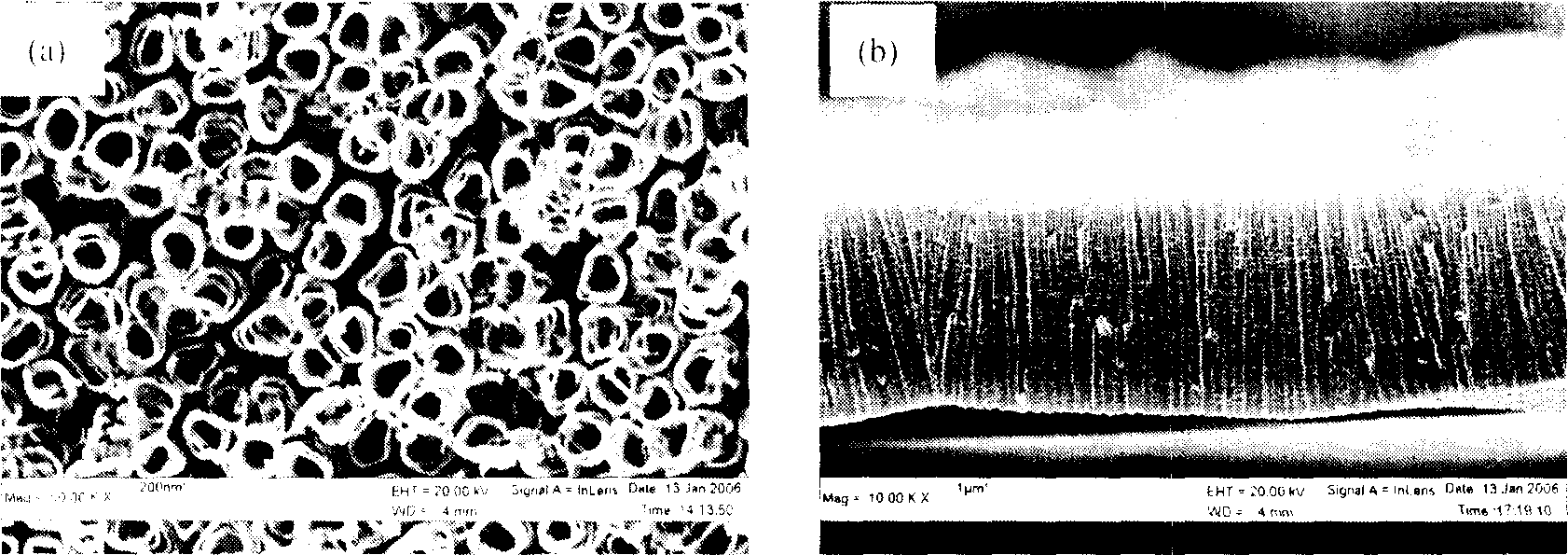

[0021] Polish the industrially pure titanium plate or titanium alloy with metallographic sandpaper until there is no scratch on the surface, then ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and dry it before use. At room temperature, use a stainless steel plate or a titanium plate as a counter electrode, take 125ml of electrolyte, and apply an anode voltage for electrochemical anodic oxidation. The samples were taken out, rinsed with deionized water, ultrasonically cleaned, and dried. The composition and experimental conditions of the electrolyte are shown in Table 1. figure 1 with figure 2 are the nanotube arrays prepared according to the conditions of Examples 1 and 2 in Table 1, respectively. It can be seen from the figure that the nanotube array is an upright, hollow, and orderly porous structure with basically the same upper and lower dimensions, with an open upper end and a closed bottom end. Titanium alloy adopts Ti-6Al-4V...

Embodiment 18~21

[0024] Similar to Example 1, the difference is that the commercially pure titanium plate or titanium alloy is ground and polished with metallographic sandpaper until there is no scratch on the surface, then ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, and dried before use. At room temperature, use a stainless steel plate or a titanium plate as a counter electrode, take 125ml of electrolyte, and apply an anode voltage for electrochemical anodic oxidation. The samples were taken out, rinsed with deionized water, ultrasonically cleaned, and dried. The composition and experimental conditions of the electrolyte are shown in Table 2. Titanium alloy adopts Ti-5Al-2.5Sn or Ti-Ni-Nb.

[0025] Reality

apply

example

Electrolyte composition

content

(%)

oxidation

(V)

anode

oxidation

time

(h)

(nm)

film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com