Bionic water-collecting composite braided fabric and its preparation method and use

A woven cloth and water collection technology, applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of inability to meet the needs of water, low water collection efficiency, and high cost, and achieve improved efficiency, good outdoor stability, and difficulty in Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Preparation of hydrophilic / hydrophobic polymer fibers:

[0053] 80 parts by weight of nylon 4 and 20 parts by weight of titanium dioxide particles (commercially available) with an average particle diameter of 100 μm are mixed uniformly, and then added to a common spinning machine to melt and spin out a fiber with a semicircular cross-section of 1 mm in diameter. Many fine protrusions of titanium dioxide particles are formed on the surface.

[0054] 80 parts by weight of polypropylene resin (commercially available) and 20 parts by weight of an average particle diameter of 100nm silicon dioxide particles (commercially available) are mixed uniformly, and then added to the spinning machine to melt and spin out a fiber with a semicircular cross-section of 2mm in diameter , the surface of this fiber is smooth and flat.

[0055] 2) Prepare composite woven cloth:

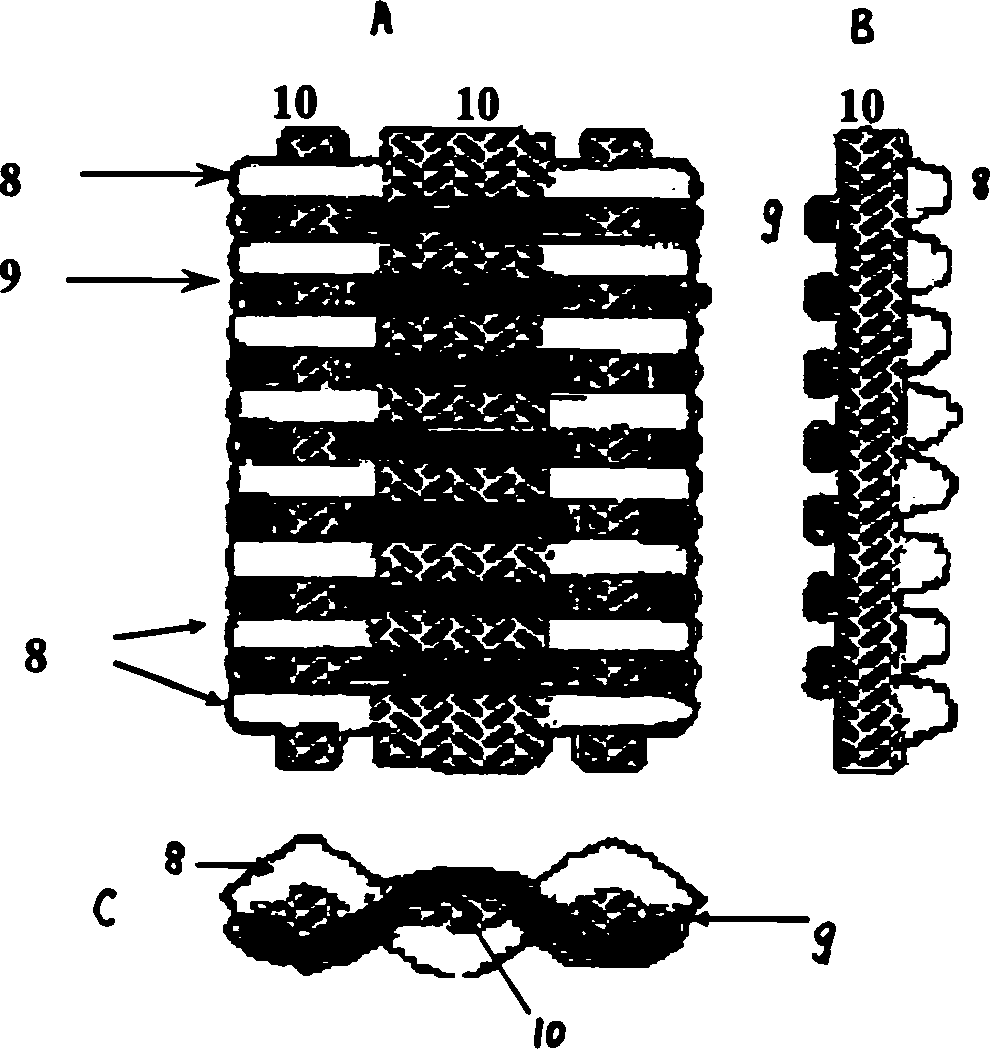

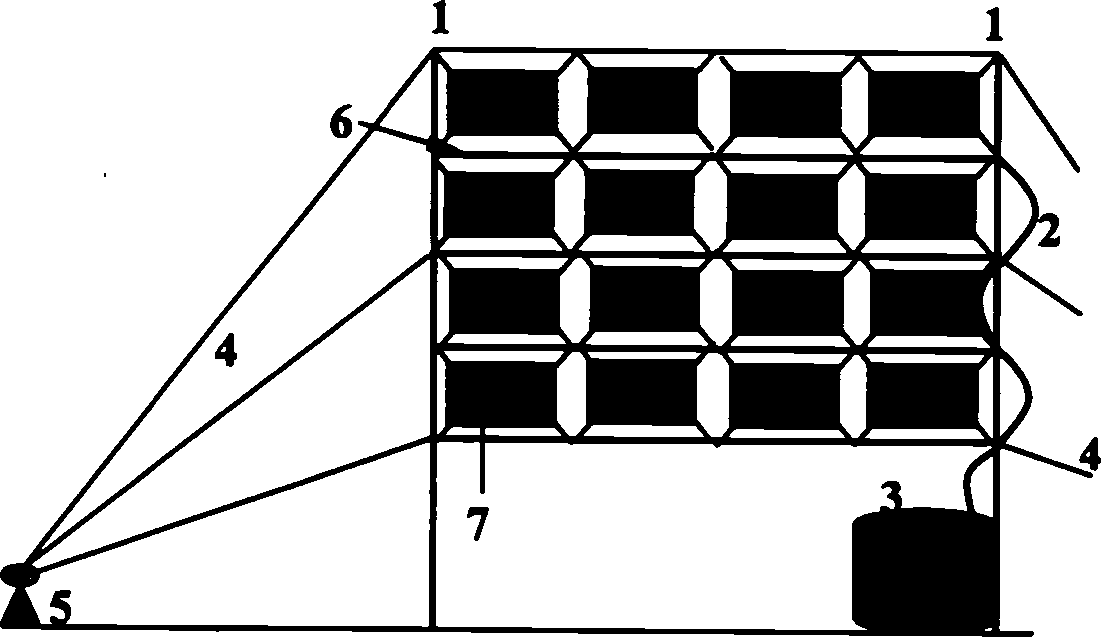

[0056] On the weaving machine, the two kinds of polymer fibers made in step 1) such as figure 1 Weaving as s...

Embodiment 2

[0059] 1) Preparation of hydrophilic / hydrophobic polymer fibers:

[0060] 70 parts by weight of polyvinylpyrrolidone and 30 parts by weight of titanium dioxide particles (commercially available) with an average particle diameter of 50 μm are uniformly mixed, and then added to a common spinning machine to melt and spin fibers with a semicircular cross-section of 2 mm in diameter. Many fine protrusions of titanium dioxide particles are formed on the surface.

[0061] 80 parts by weight of polypropylene resin and 20 parts by weight of the average particle diameter of 50nm silica particles (commercially available) are mixed uniformly, and then added to the spinning machine to melt and spin out the fiber of the semicircular cross-section of 3mm in diameter, this fiber The surface is smooth and flat.

[0062] 2) Prepare composite woven cloth:

[0063] On the weaving machine, the two kinds of polymer fibers made in step 1) such as figure 1 Weaving as shown, the wefts are alternate...

Embodiment 3

[0066] 1) Preparation of hydrophilic / hydrophobic polymer fibers:

[0067] 90 parts by weight of polymethyl methacrylate (commercially available) and 10 parts by weight of titanium dioxide particles (commercially available) with an average particle diameter of 5 μm are mixed evenly, and then added to a common spinning machine to melt and spin a semicircle with a diameter of 1.5 mm A fiber with a cross-section, the surface of which forms many fine protrusions of titanium dioxide particles.

[0068] 90 parts by weight of polyurethane resin (commercially available) and 10 parts by weight of an average particle diameter of 5nm silicon dioxide particles (commercially available) are mixed uniformly, and then added to the spinning machine to melt and spin out a fiber with a semicircular cross-section of 2.5mm in diameter , the surface of this fiber is smooth and flat.

[0069] 2) Prepare composite woven cloth:

[0070] On the weaving machine, the two kinds of polymer fibers made in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com